6-7-06 - Fifth Proof

5-3

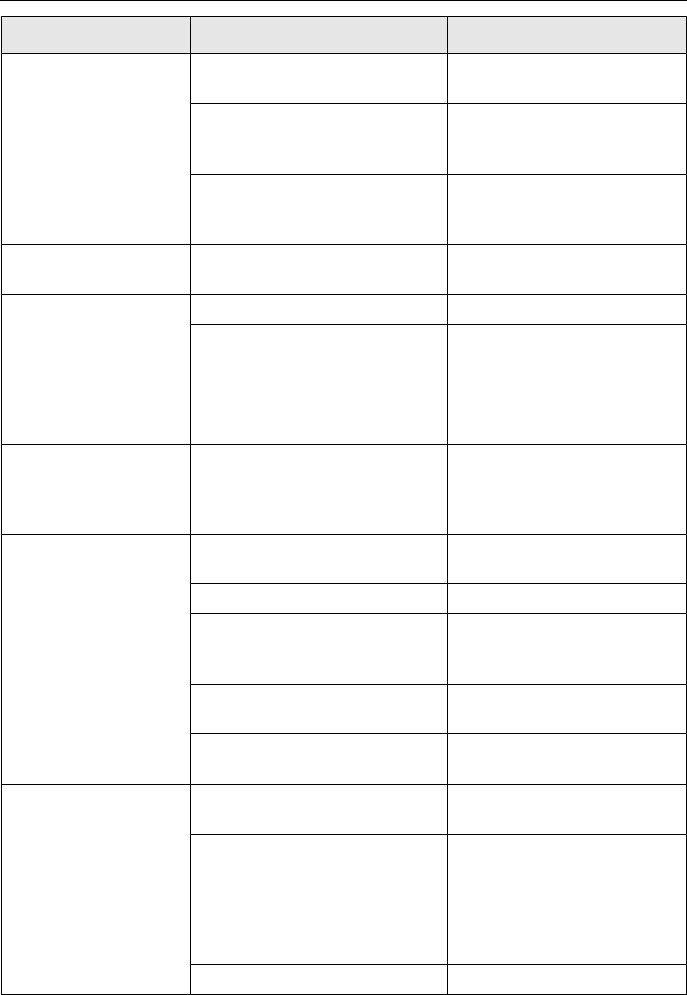

Troubleshooting

*Tested with warm oil and no more than 530 lbs (240 Kg) in the bucket. Measure the

downward drop at the attachment lock pins on the back of the mount plate.

Engine overheats. • Engine load is excessive. • Reduce ground speed.

• Reduce speed of attachment.

• Engine oil level in crankcase is

low.

• Add the appropriate engine

oil to crankcase. See engine

manual for oil specifications.

• Cooling fins and air passages

under engine blower housing

are plugged.

• Remove obstruction from

cooling fins and air passages.

Abnormal engine

vibration.

• Engine mounting bolts are

loose.

• Tighten engine mounting

bolts.

With the machines

engine turned off, the

boom creeps downward

more than 3" per hour

(less than 3" per hour is

normal for this

machine).*

• Valve spool leakage. • Contact Service Dealer.

• Cylinder seals are leaking. • Replace cylinder seals.

With the machines

engine turned off, boom

drops downward quickly

and then stops.

• Cylinder seals are leaking. • Replace cylinder seals.

The machine does not

travel in either forward or

reverse directions.

• Engine is not running at full

speed.

• Advance throttle to full engine

speed.

• Hydraulic fluid is cold. • Fully warm hydraulic fluid.

• Hydraulic fluid level is low. • Check and fill the hydraulic

fluid tank with the appropriate

hydraulic fluid.

• Fuel tanks are empty and

engine stops.

• Fill fuel tanks with fuel.

• If all above has been checked. • Contact authorized service

dealer.

Track is “cogging”. • Travelling in reverse with a

heavy load.

• Slow down travel.

• Reduce load on machine.

• Track tension spring fully

compressed.

• Stop travel and reverse

direction to allow the tension

spring to decompress.

• Check for debris in track that

could cause the track tension

spring to fully compress.

• Track tension not set properly. • Reset track tension.

Problem Possible Causes Corrective Action