8 Section 2: Assembly

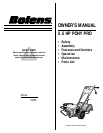

3. If oil does not flow from the check

hole, add oil as follows:

NOTE: Do not use automatic transmission

fluid or motor oil in the transmission.

(a) Clean area around the fill hole (N,

Figure 2-10) and unscrew gear oil fill

plug.

(b) If adding only a few ounces of gear oil,

use API rated GL-4 or GL-5 gear oil

having a viscosity of SAE 140, SAE

85W-140 or SAE 80W-90. If refilling

an empty transmission, use only GL-4

gear oil having a viscosity of SAE

85W-140 or SAE 140.

(c) Using a clean funnel, slowly add gear

oil until it flows from the gear oil level

check hole (N, Figure 2-10).

(d) Reinstall and tighten securely the gear

oil fill plug (M, Figure 2-9).

STEP 5: ADD MOTOR OIL TO ENGINE

The tiller is shipped without oil in the

engine.

IMPORTANT: Do not start the engine

without first adding motor oil. Severe

engine damage will result if the engine is

run without oil.

1. Refer to the separate Engine Owner’s

Manual for motor oil specifications and

capacities.

2. With the unit on level ground, move

the Depth Regulator Lever (L, Figure 2-8)

up or down until the engine is level.

3. Add motor oil as described in the

Engine Owner’s Manual.

4. Move the Depth Regulator Lever all the

way down until the highest notch is

engaged. This places the tines in the

“travel” position.

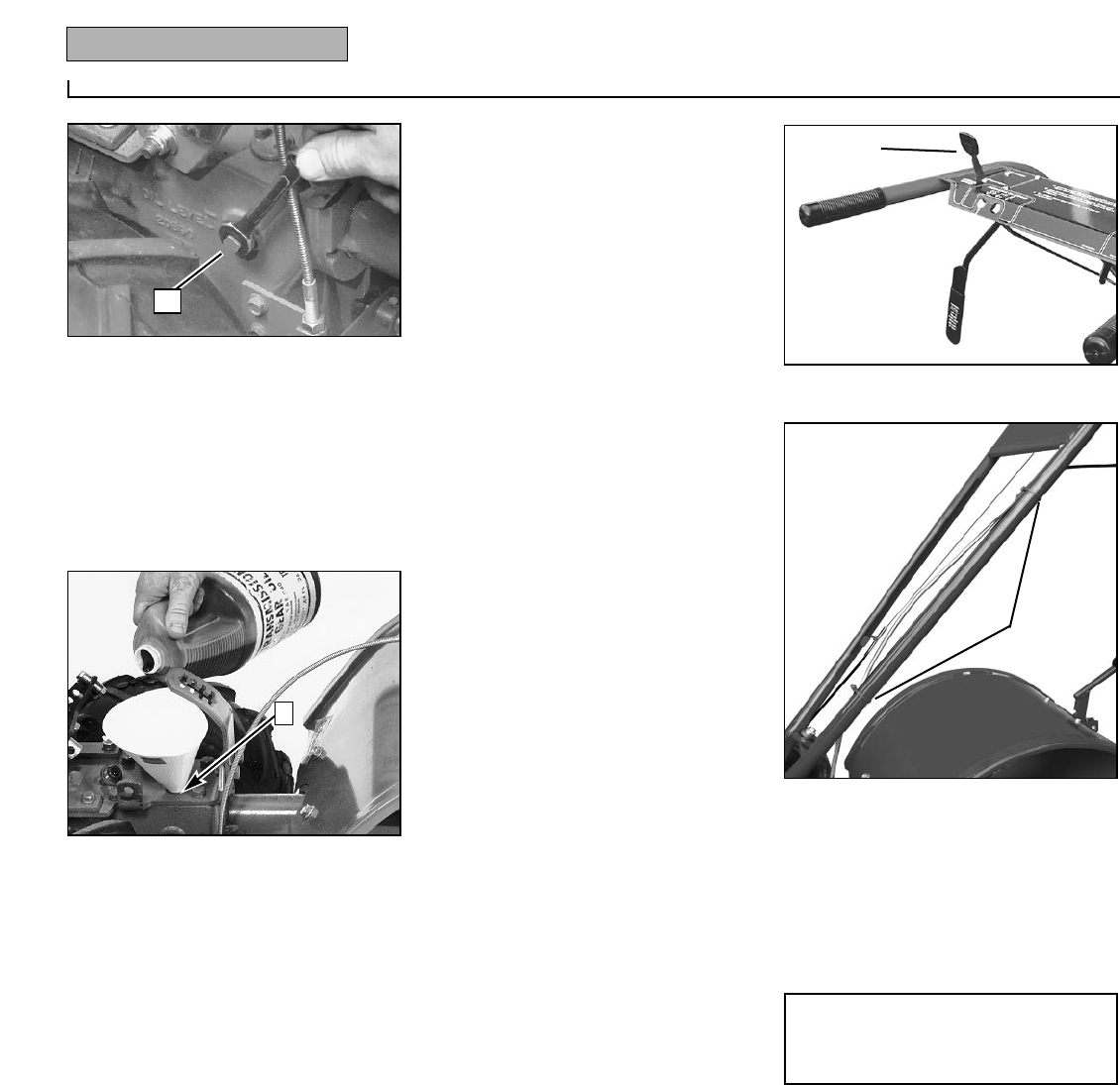

STEP 6: ATTACH WHEEL GEAR LEVER

1. Insert the Wheel Gear Lever (P, Figure

2-11) up through the slot in the control

panel that is labeled “WHEEL GEAR.”

2. Insert two #10-32 x 1/2" round head

screws down through the “+” marks on

the control panel decal and securely attach

the wheel gear mounting bracket using

two #10 lockwashers and #10-32 nuts.

3. Using a board, tap the Wheel Gear

Lever knob securely onto the lever.

4. Secure the wheel gear cable to the left-

side handlebar with two plastic ties

(S, Figure 2-12), located about two feet

apart. Snip off any excess tie length with

scissors.

STEP 7: CHECK AIR PRESSURE

IN TIRES

Use a tire pressure gauge to check the air

pressure in both tires. Deflate or inflate

both tires equally to 15-to-20 PSI (pounds

per square inch). Be sure that both tires

are inflated equally or the unit will pull to

one side.

STEP 8: CHECK HARDWARE FOR

TIGHTNESS

Inspect the hardware on the unit and

tighten any loose screws, bolts and nuts.

This completes the assembly steps.

Be sure to read the rest of this Manual

before you operate your tiller.

Figure 2-9: Gear oil level check plug.

M

Figure 2-10: Adding gear oil.

Figure 2-11: Attach Wheel Gear Lever.

P

N

Figure 2-12: Attach wheel gear cable with

cable ties (S).

S