Section 5: Maintenance 17

2. Unscrew plastic gear oil fill plug from

top of transmission.

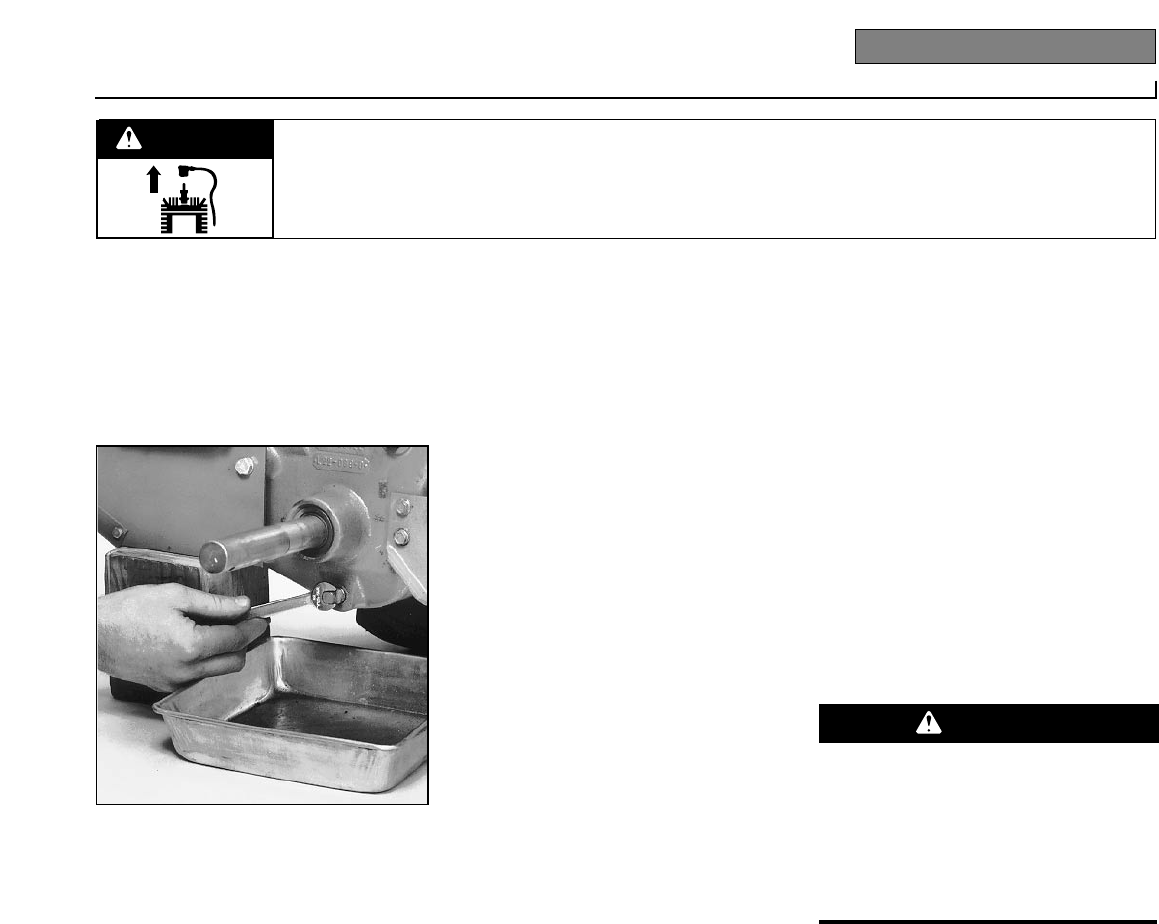

3. Place a clean pan below the transmis-

sion drain plug (see Figure 5-3) and then

remove the drain plug. Oil will flow from

the drain hole (it may flow slowly, espe-

cially in cold temperatures).

4. Remove transmission gear oil level

check plug located a few inches above left-

side wheel shaft.

5. When oil stops flowing, tilt transmis-

sion forward to drain oil from rear of

transmission.

6. After draining oil, clean threads of drain

plug, apply non-hardening, removable

gasket sealant to threads, and securely

reinstall drain plug.

7. Use a clean funnel to slowly add SAE

140 or SAE 85W-140 weight gear oil (API

rating of GL-4 only) to the transmission.

The transmission holds approximately 3-

1/4 pints (52-54 ounces). Tilt the tiller

slightly backwards to make sure the gear

oil reaches the rear (tine) end of the trans-

mission. Stop adding gear oil when it

begins to flow from the oil level check hole

on the side of transmission.

8. Securely reinstall oil level check plug.

9. Securely reinstall gear oil fill plug on

top of transmission.

10. Reinstall wheel and remove prop.

ENGINE OIL SERVICE

Check motor oil level before starting

engine each day and after each 5 hours of

continuous operation. Running engine

when oil level is low will quickly ruin

engine.

It is recommended that you change motor

oil after every 10 hours of operation and

even sooner when operating in extremely

dirty or dusty conditions.

A. To Check Motor Oil Level:

1. Move tiller to level area and stop

engine.

2. Level engine by putting Depth Regula-

tor Lever into second notch from top.

3. Clean area around oil dipstick or oil fill

tube (whichever applies) to prevent dirt

from falling into crankcase.

4. On engines with an oil fill tube, remove

filler cap and add oil (if required) until it

reaches top of tube. Reinstall filler cap.

5. On engines with a dipstick, remove,

wipe clean, and reinstall finger-tight.

Remove dipstick again and check reading.

Add oil (if required) to FULL mark. Do not

overfill. Refer to Engine Owner’s Manual

for complete details.

B. To Change Motor Oil:

Change motor oil as instructed in separate

Engine Owner’s Manual.

AIR CLEANER SERVICE

The engine air cleaner filters dirt and dust

out of the air before the air enters the car-

buretor. Operating the engine with a dirty,

clogged air filter can cause poor perfor-

mance and damage the engine. Never

operate the engine without an air cleaner

installed. Inspect and service the air

cleaner more often if operating in very

dusty or dirty conditions.

Service the air cleaner as instructed in the

Engine Owner’s Manual.

SPARK PLUG SERVICE

Inspect and clean or replace the spark

plug after every 100 operating hours or

annually. Clean the plug and set the gap

as described in Engine Owner’s Manual.

SPARK ARRESTER SCREEN SERVICE

If the engine muffler is equipped with a

spark arrester screen, remove and clean it

according to the time intervals and

instructions in the separate Engine

Owner’s Manual.

ENGINE CLEANING

The engine must be kept clean to assure

smooth operation and to prevent damage

from overheating. Refer to the Engine

Owner’s Manual for specific repair and

cleaning instructions. All inspections and

services must be done with the engine

shut off and cool to the touch.

CARBURETOR/GOVERNOR CONTROL

ADJUSTMENTS

The carburetor was adjusted at the factory

for best operating speed. Refer to the

separate Engine Owner’s Manual for any

adjustment information or see your autho-

rized engine service dealer.

The governor controls the maximum safe

operating speed and protects the engine

and all moving parts from damage caused

by overspeeding. Do not tamper with the

engine governor settings. Seek an autho-

rized service dealer if a problem exists.

THROTTLE CONTROL ADJUSTMENT

If the engine does not respond to various

throttle lever settings, refer to the separate

Engine Owner’s Manual for service infor-

mation or contact your local authorized

engine service dealer.

WHEEL GEAR CABLE ADJUSTMENT

When the Wheel Gear Lever is in DISEN-

GAGE, the wheels will roll freely (free-

wheel). The wheels should not roll freely

when the lever is in ENGAGE. If the

Figure 5-3: Remove drain plug to drain

transmission gear oil (also remove oil fill

plug and oil level check plug).

Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to come to

a complete stop, remove ignition key on electric start models, disconnect spark plug wire and move wire

away from spark plug.

Failure to follow these instructions can result in serious personal injury or property damage.

WARNING

Operators shall not tamper with the

engine governor settings; the governor

controls the maximum safe operating

speed to protect the engine and all

moving parts from damage caused by

overspeed. Authorized service shall be

sought if a problem exists.

WARNING