Heater must be located so that any water leaks will not

damage the structure of adjacent area. PVC pipe may

be glued directly into header unions.

FLOW RATES

MODEL PIPE SIZE MIN.GPM *MAX.GPM

185 1-1/4"-1-1/2" - 2 20 125

265 1-1/4"-1-1/2" - 2 25 125

335 1-1/4"-1-1/2" - 2 35 125

405 1-1/4"-1-1/2" - 2 40 125

*When flow rates exceed maximum GPM an external

auxiliary bypass valve is required. See external bypass

valve section for details.

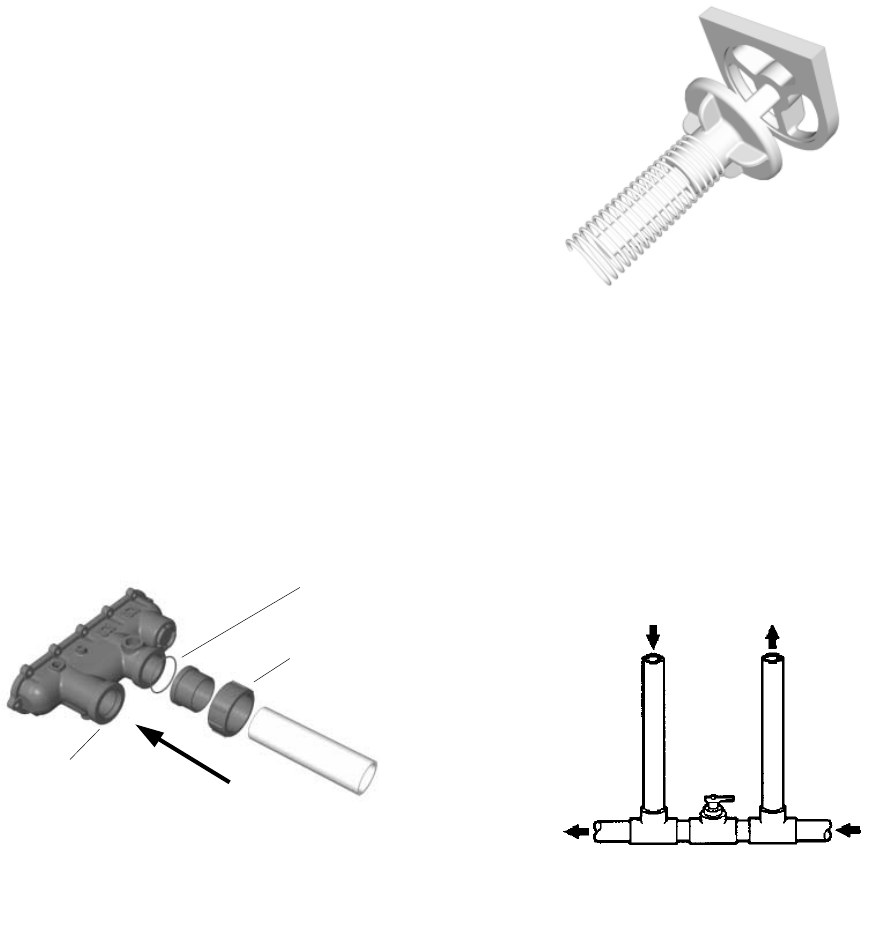

CONNECTIONS

Before attaching the 2-inch unions to the inlet/outlet

header, make sure the o-rings are properly seated in the

grooves. Use AquaLube or equivalent non-petroleum

based lubricant on the o-ring. Tighten the unions hand

tight. Glue PVC piping directly to the unions.

INLET/OUTLET HEADER

Flange Gasket

Fig. #2002.1

UNITHERM GOVERNOR OPERATION

The patented Unitherm Governor is a thermostatic

mixing valve specifically designed to maintain constant

heater internal temperature between 105° to 115°F

despite continually changing flow rates from the filter

and changing pool temperatures. This narrow range is

needed to prevent damaging condensation on the burn-

ers which will occur if the heater runs for any length of

time below 100°F. It is also needed to inhibit scale

formation in the tubes by maintaining temperatures

well below accelerated scaling temperatures.

16

INTERNAL AUTOMATIC BY-PASS VALVE

In addition to the Unitherm Governor, a built-in

automatic by-pass valve is provided in the in/out

header. While the Unitherm Governor responds to the

changes in water temperature in the heater, the internal

by-pass valve automatically responds to changes in

water pressure in the piping system. Proper amount of

water flow is maintained through the heater under

varying pressures dictated by the conditions of the

pump and filter.

Fig.#2003

EXTERNAL AUXILIARY BYPASS VALVE

(Where Required)

An auxiliary bypass valve should be used when flow

rates exceed 125 GPM (usually a high performance

pump size larger than two horsepower will exceed this

flow rate). This valve is required to complement the

function of the automatic bypass valve, particularly

when starting the heater in winter or early spring when

the spa or pool temperature is down below 50°F. It also

serves to eliminate needless pressure drop through the

heater and accompanying reduction in the flow rate to

the spa jets, etc.

From Heater To Heater

To Pool From Pool

AUXILLARY BYPASS VALVE

(DO NOT USE GATE VALVE)

Fig. # 8150.0s

AUXILIARY BYPASS VALVE ADJUSTMENT

To set bypass: With clean filter, adjustment is made

by feeling the inlet and outlet pipes at the heater. Outlet

pipes should be slightly warmer than inlet and comfort-

able to the touch. If pipe is hot, close bypass; if cold,

open bypass.

Plumbing from the heater back to the pool must not have

any valves or restriction that could prevent flow when the

pump is operating.

CAUTION: A source of additional heated water, i.e. solar

systems, must be connected to the heater outlet pipe. If

this is connected to the heater inlet, incorrect pool water

temperature readings will be displayed on the heater

control panel.

Header Flange

Inlet