22

English

8. Maintenace

(1)

MA1

MA2

MA3

MA4

MA5

■ OILING PORT

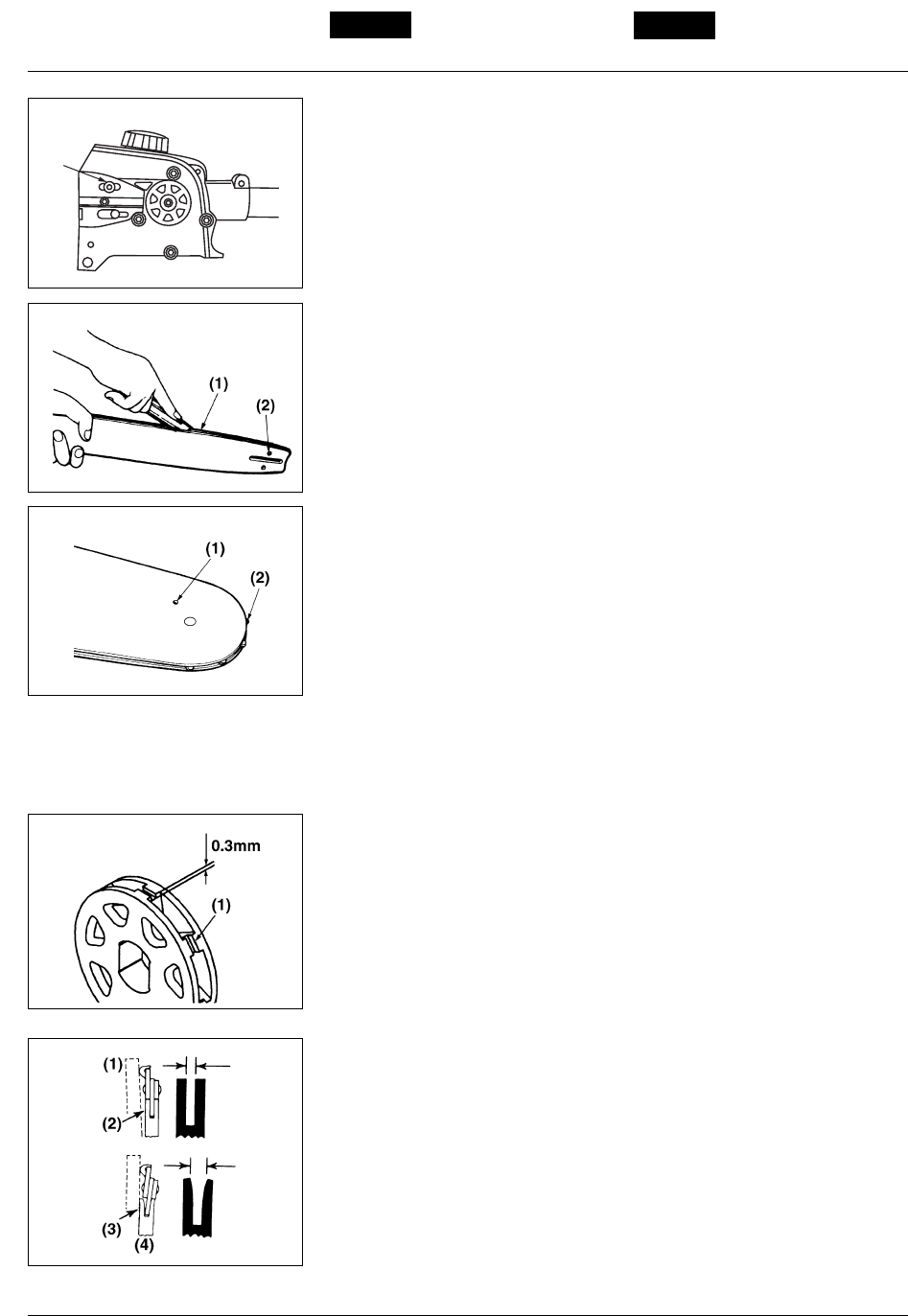

Dismount the guide bar and check

the oiling port for clogging. (MA1)

(1) Oiling port

■ GUIDE BAR

Remove sawdust in the bar groove

and the oiling port. (MA2)

(1) Groove

(2) Oiling port

(Type: Sprocket nose)

Grease the nose sprocket from the

feeding port on the tip of the bar.

(MA3)

(1) Grease port

(2) Sprocket

■ OTHERS

Check for fuel leakage and loose

fastenings or damage to major parts,

especially housing joints and guide

bar mounting. If any defects are

found, make sure to have them

repaired before operating again.

■ SPROCKET

Check for extensive wear, and

replace it when the teeth are worn

over 0.3mm. (MA4)

(1) Sprocket

■ GUIDE BAR

The bar rail should always be a

square. Check for wear of the bar

rail. Apply a ruler to the bar and the

outside of a cutter. If a gap is

observed between them, the rail is

normal. Otherwise, the bar rail is

worn. Such a bar needs to be

corrected or replaced.(MA5)

(1) Ruler (2) Gap

(3) No gap (4) Chain tilts

中 文

■出油口

拆下导板并检查出油口有无堵塞。

(MA1)

(1)出油口

■导板

清理导板凹槽和出油口中的锯屑。

(MA2)

(1)凹槽

(2)出油口

(类型:链齿前端)

从导板顶端的供油口对链齿前端进行润

滑。(MA3)

(1)润滑口

(2)链齿

■其它

请检查是否有燃料泄漏、紧固件的松动

或主要部件的损坏,尤其是各个罩的结

合处以及导板的安装情况。如果发现任

何问题,请务必在再次操作机器之前将

其维修好。

■链齿

请检查链齿有无过度磨损。当齿的磨损

达0.3mm以上时应进行更换。

(MA4)

(1)链齿

■导板

・板轨应保持方形,请检查板轨的磨损

情况。将尺放平于板和刀具的外侧,

如果中间有缝隙,说明板轨正常;否

则表明板轨有磨损。请修整好有磨损

的板,或将其更换。(MA5)

(1)尺

(2)缝隙

(3)无缝隙

(4)链倾角

8. 检修