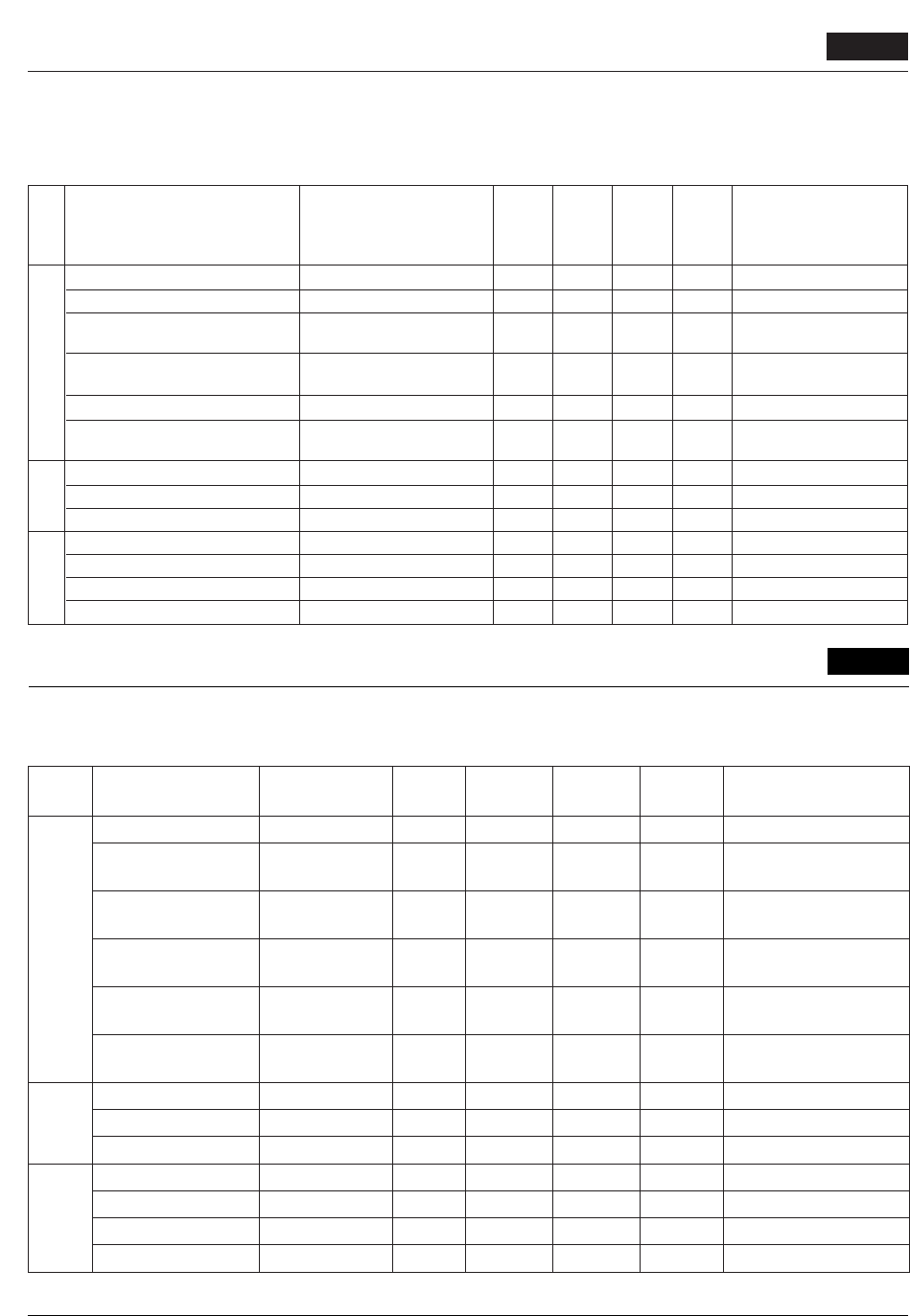

21

Every Every Every

25 50 100

System/compornent Procedure Before hours hours hours note

use after after after

fuel leaks, fuel spillage wipe out ✔

fuel tank, air filter, fuel filter inspect/clean ✔✔ replace, if necessary

see ■ADJUSTING replace carburetor

idle adjusting screw ✔

IDLING SPEED (p.20) if necessary

clean and readjust GAP: .025in(0.6~0.7 mm)

spark plug ✔

electrode gap replace, if necessary

cylinder fins, intake air cooling vent clean ✔

muffler, spark arrester, clean,

✔

cylinder exhaust port remove piled up carbon

throttle lever, ignition switch check operation ✔

gear case grease ✔

screws/nuts/bolts tighten/replace ✔✔not adjusting screws

oiling port clean ✔

guide bar clean ✔

sprocket inspect/replace ✔

saw chain inspect/replace ✔

ENGINE

SHAFT

CUTTING UNIT

■ MAINTENANCE CHART

Maintenance, replacement, or repair of the emission control device

and systems may be performed by any non-road engine repair

establishment or individual.

8. Maintenance

English

中 文

系统/部件 步 骤 使用前 每使用25 每使用50 每使用100 补 充

小时后 小时后 小时后

引擎 燃料泄漏、燃料溢出 擦拭干净 ✓

燃料箱、空气滤清器、 检查/清洁 ✓ ✓ 如有必要请进行更换。

燃料滤清器

空转调节螺钉 请参见■调节 ✓ 如果必要请更换化油器。

空转速度(p.20)

火星塞 进行清洁并重新 ✓ 间隙:0.6_0.7mm,

调节电极间隙 如有必要请进行更换。

汽缸散热片、进气冷 进行清洁 ✓

却孔

消音器、汽缸排气口 进行清洁, ✓

清除积累的碳

轴 加油柄、点火开关 检查操作 ✓

齿轮箱 进行润滑 ✓

螺钉/螺母/螺栓 进行紧固/更换 ✓ ✓ 不调节螺钉

切割机 机油口 进行清洁 ✓

导板 进行清洁 ✓

链齿 检查/更换 ✓

锯链 检查/更换 ✓

8. 检修

任何非公路引擎维修商或个人都可以进行发射控制设备和系统的检修、更换或维修。

■检修表