Add only distilled water. Never add additional acid

or any other chemicals to the battery after initial acti-

vation.

NOTE: After operating the lawn tractor for a long peri-

od of time, check the fluid level in the battery as it can

overheat and lose fluid.

CHARGING THE BATTERY

The engine is equipped with an alternator which

charges battery when tractor is operated. Under nor-

mal conditions, the battery only needs to be charged

before, during and after off-season storage. Follow

the instructions under "Off-Season Storage."

To charge the battery: Make certain fluid level in

each cell is between LOWER LEVEL and UPPER

LEVEL. Use a 12 volt automotive charger which is

rated less than 10 amps.

12.5 H.P. Lawn Tractor: Charge for 14 to 16 hours.

DO NOT CHARGE LONGER THAN 30 HOURS.

18 H.P. Lawn Tractor: Charge for a minimum of 3

hours and a maximum of 5 hours.

REMOVING / INSTALLING / JUMP STARTING

WARNING: When removing or installing

the battery, follow these instructions to

prevent the screwdriver from shorting

against the frame.

Removing the Battery: Disconnect negative cable

first, then positive cable.

Installing the Battery: Connect positive cable first,

then negative cable.

Jump Starting

1. First, connect end of one jumper cable to the posi-

tive terminal of the good battery, then the other

end to the positiveterminal of the dead battery.

2. Connect the other jumper cable to the negative

terminal of the good battery, then to the FRAME

OF THE UNIT WITH THE DEAD BATTERY.

TIRES

Recommended operating tire pressure is approxi-

mately 12 p.s.i. (check sidewall of tire for tire manu-

facturer's recommended pressure). Maximum tire

pressure under any circumstances is 30 p.s.i. Equal

tire pressure should be maintained on all tires.

When installing a tire to the rim, be certain rim is

clean and free of rust. Lubricate both the tire and rim

generously. Never inflate to over 30 p.s.i, to seat

beads.

WARNING: Excessive pressure (over 30

p.s.i.) when seating beads may cause

tire/rim assembly to burst with force suf-

ficient to cause serious injury.

BELTREMOVAL AND REPLACEMENT

WARNING: Disconnect the spark plug

wire and ground it against the engine.

Block the wheels of the unit.

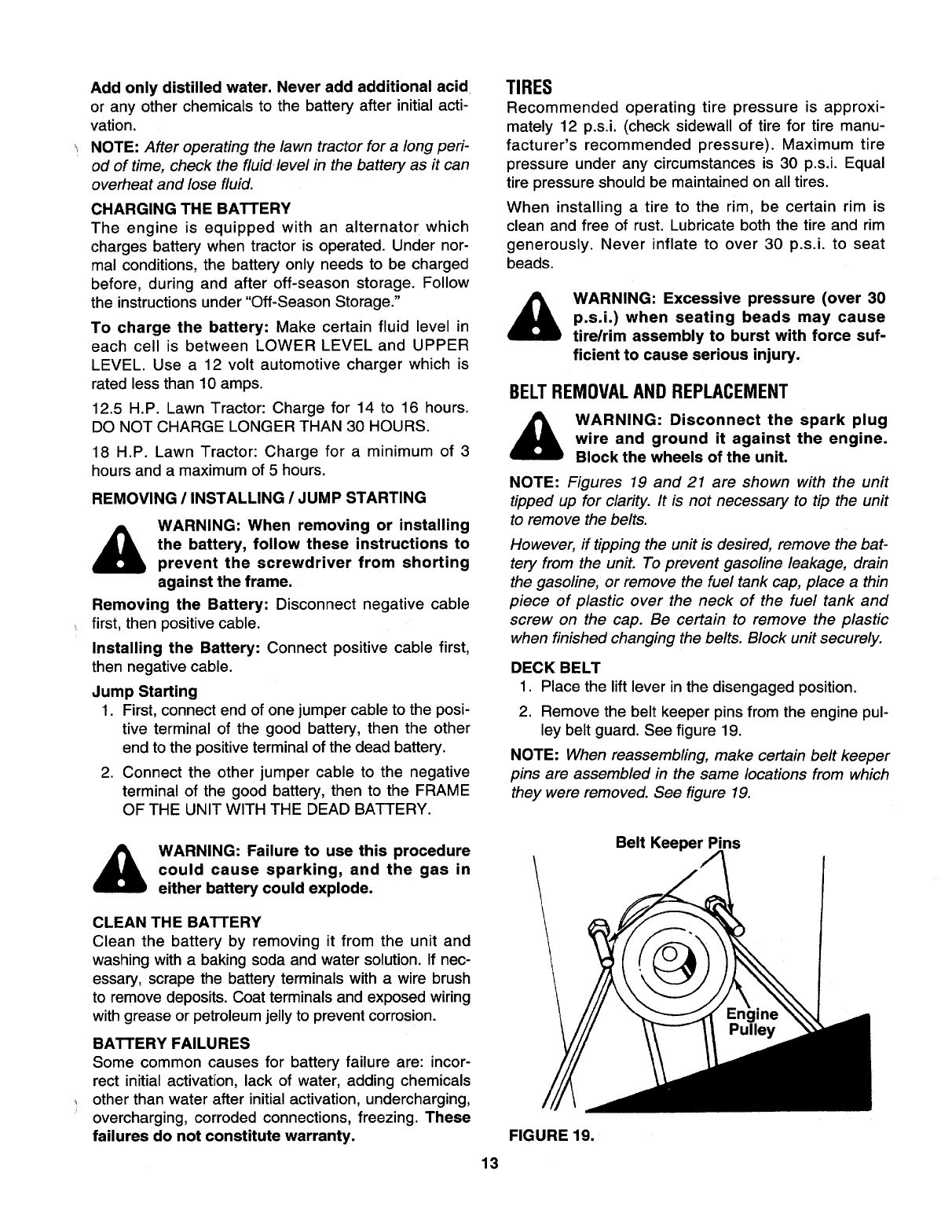

NOTE: Figures 19 and 21 are shown with the unit

tipped up for clarity. It is not necessary to tip the unit

to remove the belts.

However, if tipping the unit is desired, remove the bat-

tery from the unit. To prevent gasoline leakage, drain

the gasoline, or remove the fuel tank cap, place a thin

piece of plastic over the neck of the fuel tank and

screw on the cap. Be certain to remove the plastic

when finished changing the belts. Block unit securely.

DECK BELT

1. Place the lift lever in the disengaged position.

2. Remove the belt keeper pins from the engine pul-

ley belt guard. See figure 19.

NOTE: When reassembling, make certain belt keeper

pins are assembled in the same locations from which

they were removed. See figure 19.

&

WARNING: Failure to use this procedure

could cause sparking, and the gas in

either battery could explode.

Belt Keeper Pins

CLEAN THE BATTERY

Clean the battery by removing it from the unit and

washing with a baking soda and water solution. If nec-

essary, scrape the battery terminals with a wire brush

to remove deposits. Coat terminals and exposed wiring

with grease or petroleum jelly to prevent corrosion.

BATTERY FAILURES

Some common causes for battery failure are: incor-

rect initial activation, lack of water, adding chemicals

other than water after initial activation, undercharging,

overcharging, corroded connections, freezing. These

failures do not constitute warranty.

FIGURE 19.

13