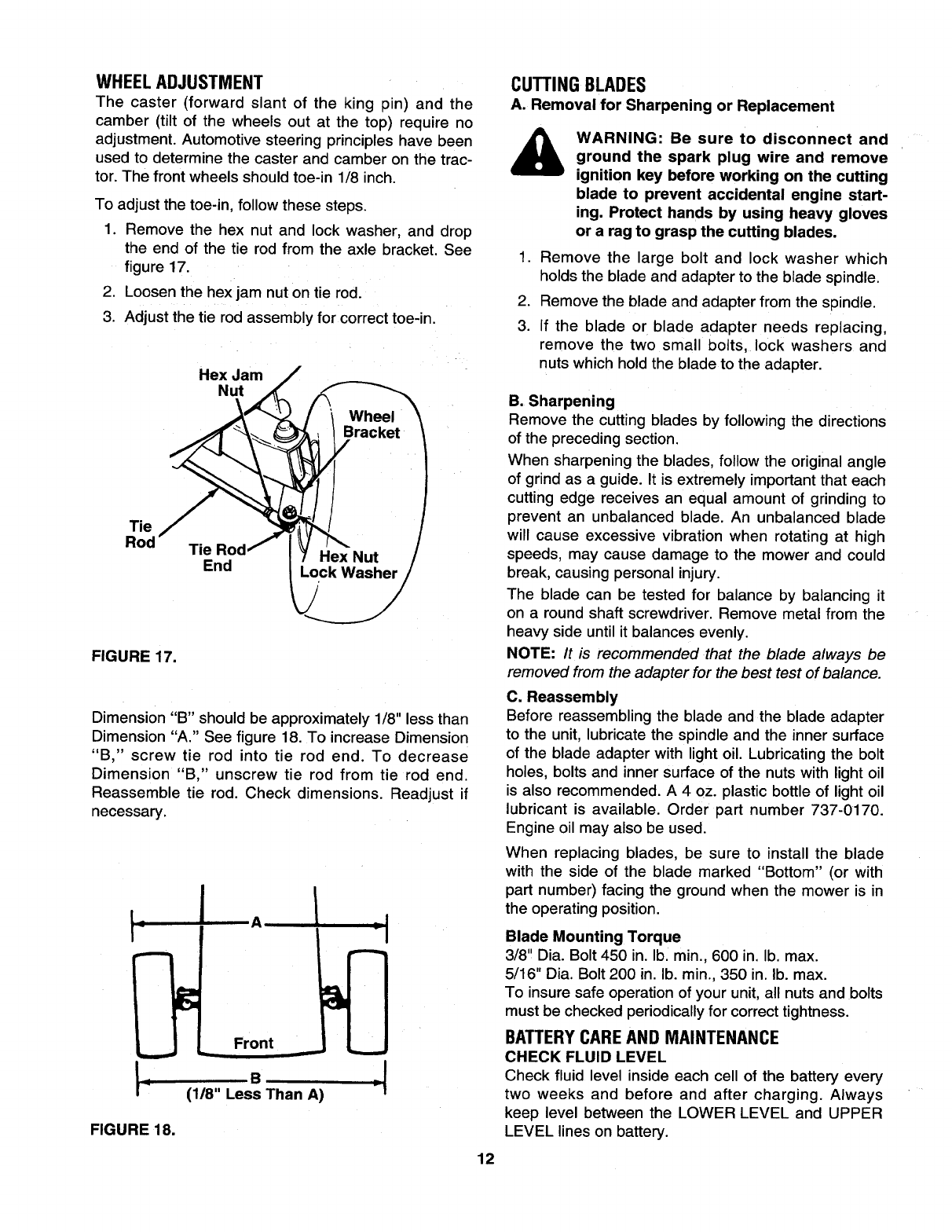

WHEEL ADJUSTMENT

The caster (forward slant of the king pin) and the

camber (tilt of the wheels out at the top) require no

adjustment. Automotive steering principles have been

used to determine the caster and camber on the trac-

tor. The front wheels should toe-in 1/8 inch.

To adjust the toe-in, follow these steps.

1. Remove the hex nut and lock washer, and drop

the end of the tie rod from the axle bracket. See

figure 17.

2. Loosen the hex jam nut on tie rod.

3. Adjust the tie rod assembly for correct toe-in.

Hex Jam

NutI

o Tie Rod _

End

FIGURE 17.

/

, Bracket

!,

\ /

Hex Nut

Lock Washer /

J.__j

Dimension "B" should be approximately 1/8" less than

Dimension "A." See figure 18. To increase Dimension

"B," screw tie rod into tie rod end. To decrease

Dimension "B," unscrew tie rod from tie rod end.

Reassemble tie rod. Check dimensions. Readjust if

necessary.

Front

I °

4 (1/8" Less Than A)

i .I

I

FIGURE 18.

12

CUTTING BLADES

A. Removal for Sharpening or Replacement

&

WARNING: Be sure to disconnect and

ground the spark plug wire and remove

ignition key before working on the cutting

blade to prevent accidental engine start-

ing. Protect hands by using heavy gloves

or a rag to grasp the cutting blades.

1. Remove the large bolt and lock washer which

holds the blade and adapter to the blade spindle.

2. Remove the blade and adapter from the spindle.

3. If the blade or blade adapter needs replacing,

remove the two small bolts, lock washers and

nuts which hold the blade to the adapter.

B. Sharpening

Remove the cutting blades by following the directions

of the preceding section.

When sharpening the blades, follow the original angle

of grind as a guide. It is extremely important that each

cutting edge receives an equal amount of grinding to

prevent an unbalanced blade. An unbalanced blade

will cause excessive vibration when rotating at high

speeds, may cause damage to the mower and could

break, causing personal injury.

The blade can be tested for balance by balancing it

on a round shaft screwdriver. Remove metal from the

heavy side until it balances evenly.

NOTE: It is recommended that the blade always be

removed from the adapter for the best test of balance.

C. Reassembly

Before reassembling the blade and the blade adapter

to the unit, lubricate the spindle and the inner surface

of the blade adapter with light oil. Lubricating the bolt

holes, bolts and inner surface of the nuts with light oil

is also recommended. A 4 oz. plastic bottle of light oil

lubricant is available. Order part number 737-0170.

Engine oil may also be used.

When replacing blades, be sure to install the blade

with the side of the blade marked "Bottom" (or with

part number) facing the ground when the mower is in

the operating position.

Blade Mounting Torque

3/8" Dia. Bolt 450 in. lb. min., 600 in. lb. max.

5/16" Dia. Bolt 200 in. lb. rain., 350 in. lb. max.

To insure safe operation of your unit, all nuts and bolts

must be checked periodically for correct tightness.

BATTERYCAREAND MAINTENANCE

CHECK FLUID LEVEL

Check fluid level inside each cell of the battery every

two weeks and before and after charging. Always

keep level between the LOWER LEVEL and UPPER

LEVEL lines on battery.