Owner Service 19

15916 (Rev. 3/30/2007)

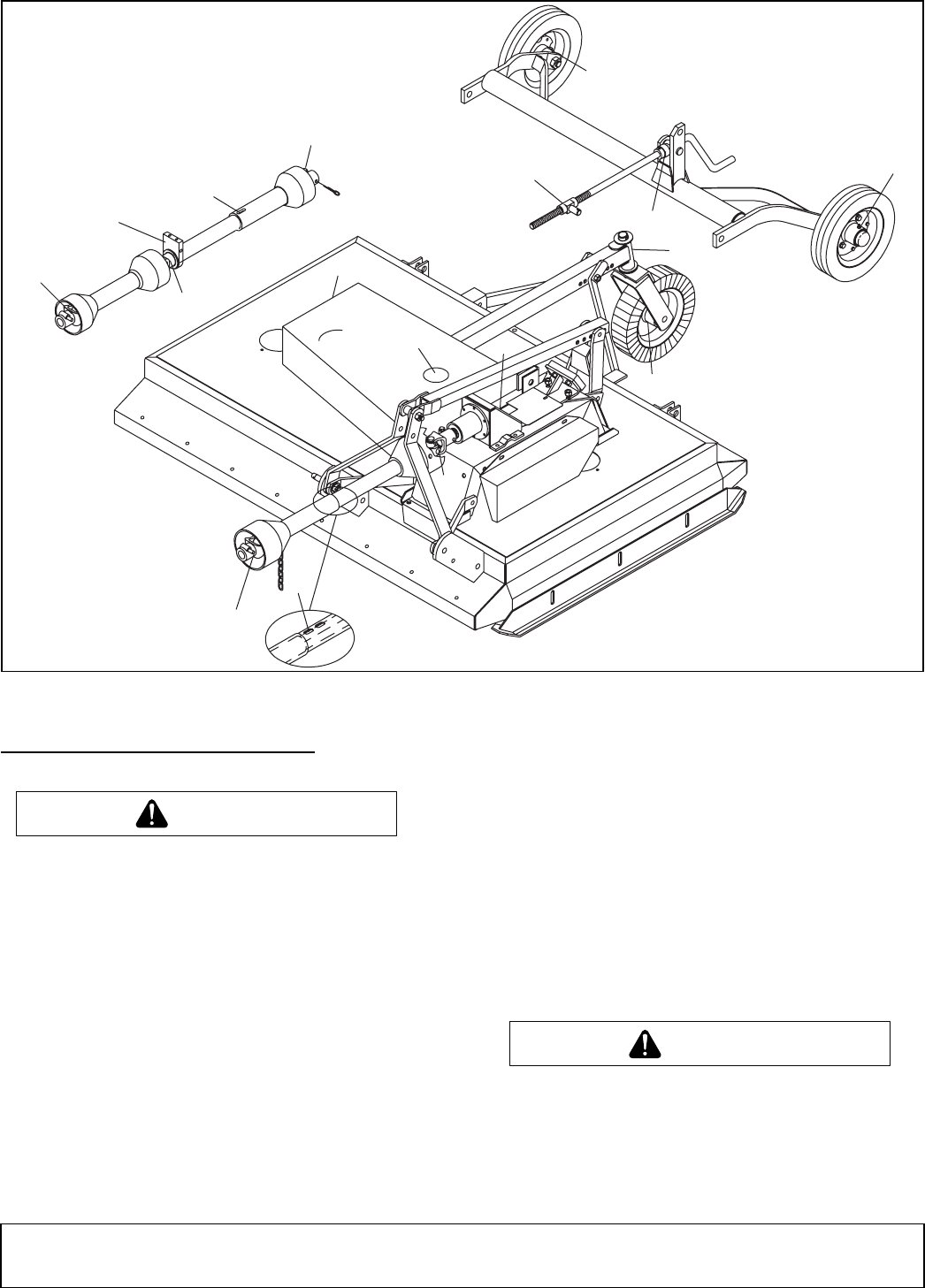

Figure 7. Lubrication Points

BLADE SERVICING (FIGURE 8)

On pull-type units, a pin is installed to prevent

the height adjustment crank from detaching. Do

not operate or service unit unless pin is installed.

Blocking the cutter before working underneath provides

additional safety. If a mechanical or hydraulic failure

occurs, the blocks will support the cutter and prevent

anyone under it from being crushed.

Inspect blades, each time before operating cutter, for

condition and proper installation. Check to be sure

blades are snug but still swivel on blade pin (see Blade

Installation, page 20). Replace any blade that is bent,

excessively nicked, worn or has any other damage.

Small nicks can be ground out when sharpening.

Blade Removal (Figure 8)

Rotate crossbar until blade pin assembly is directly

below access hole in rear of cutter frame. Remove bolt

(1) and blade pin lock clip (2). Slide keyhole plate (3)

out of blade pin groove and remove. Remove spacers

and drive pin out of crossbar.

NOTICE

■ If blade pin is seized in crossbar and extreme

force will be required to remove it, support cross-

bar from below to prevent damage to spindle.

Your dealer can supply genuine replacement

blades. Substitute blades may not meet original

equipment specifications and may be dangerous.

MOUNTED

PULL-TYPE

6

9

8

7

5

4

3

2

1

14

1

13

12

10

11

CD3847

7

9

PULL-TYPE

WARNING

CAUTION

CAUTION