30 Assembly

MAN0450 (10/28/2005)

ASSEMBLY

GENERAL ASSEMBLY INSTRUCTIONS

Backhoe assembly is the responsibility of the WOODS

dealer. The backhoe should be delivered to the owner

completely assembled, lubricated and adjusted for nor-

mal operating conditions.

Set backhoe up as received from the factory with these

instructions and illustrations.

The backhoe must only be mounted with a tractor 3-

point hitch using WOODS 3-Point Mount kit or a

WOODS sub-frame kit. See WOODS 3-Point Mount

manual for mount installation instructions.

When mounting this backhoe on a tractor using a sub-

frame mount, special assembly instructions (which are

contained in another manual furnished with the sub-

frame) apply to some of the assembly procedures.

The backhoe is shipped partially assembled. Assembly

will be easier if components are aligned and loosely

assembled before tightening hardware.

NOTE: References to right, left, forward and rearward

directions are determined from the backhoe operator

seat position facing rearward.

Figure 18. Backhoe Directions

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Only mount this backhoe on Category 1 tractors

with 800 lb. lift capacity at 24" behind 3-point lift

arm hitch balls.

Keep hands and body away from pressurized

lines. Use paper or cardboard, not hands or other

body parts to check for leaks. Wear safety goggles.

Hydraulic fluid under pressure can easily penetrate

skin and will cause serious injury or death.

Make sure that all operating and service person-

nel know that if hydraulic fluid penetrates skin, it

must be surgically removed as soon as possible by

a doctor familiar with this form of injury or gan-

grene, serious injury, or death will result. CON-

TACT A PHYSICIAN IMMEDIATELY IF FLUID

ENTERS SKIN OR EYES. DO NOT DELAY.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

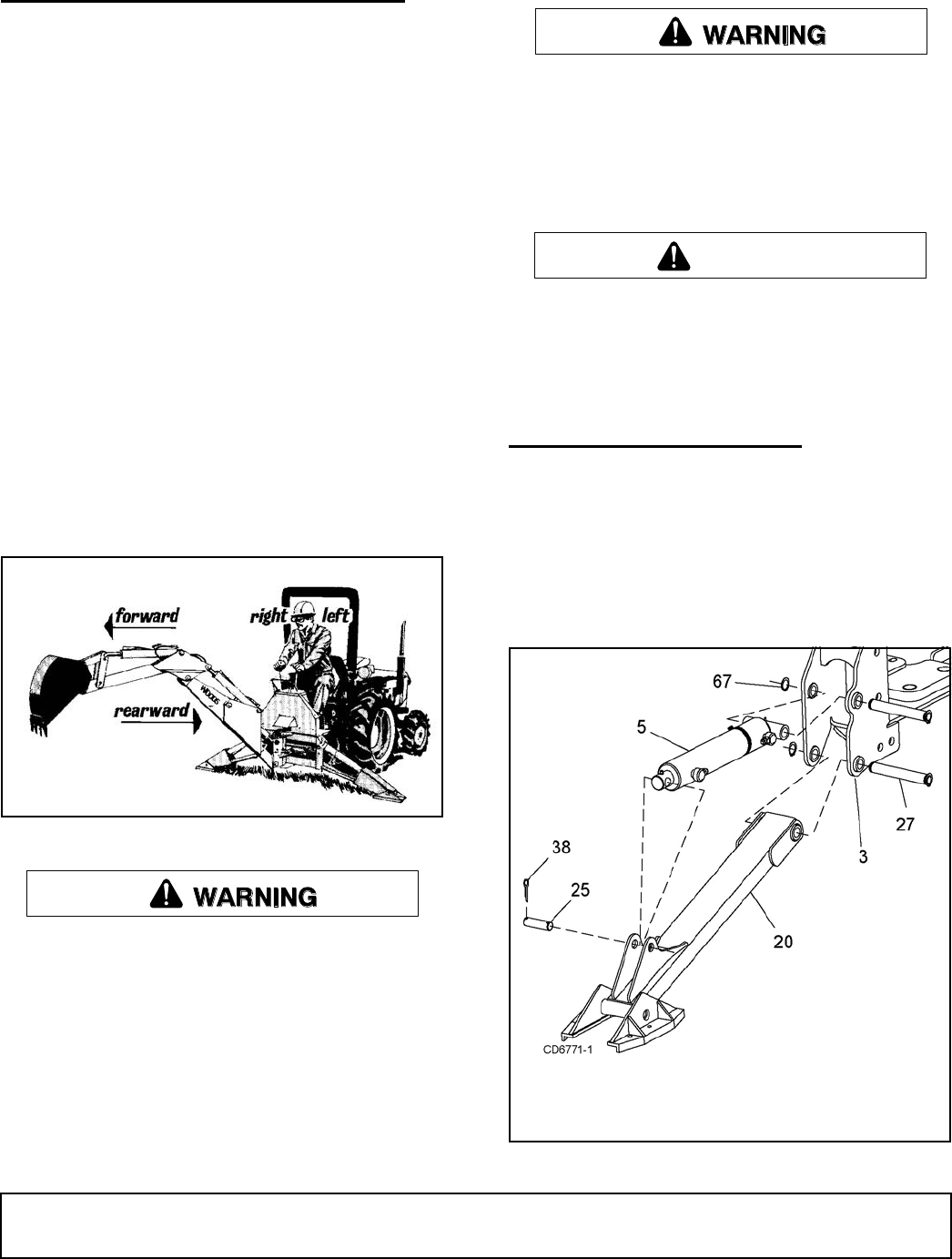

STABILIZER INSTALLATION

Remove stabilizer arms from pallet.

Remove pivot pins (27) from their shipping position.

Attach stabilizer arm (20) to main frame (3) with pivot

pin (27) and secure with snap ring (67).

Attach stabilizer cylinder (5) to stabilizer arm with pivot

pin (25) and secure with two cotter pins (38).

Figure 19. Stabilizer Arm Assembly - Left Side

CAUTION

3. Main frame

5. 2-1/2 x 11" Hyd cylinder

20. Stabilizer arm

25. Pin, .88 x 3.06"

27. Pivot pin, 1 x 6.67"

38. 3/16 X 1-1/2 Cotter pin

67. Ring, .042 x .925 ext.