Dealer Service 25

MAN0450 (10/28/2005)

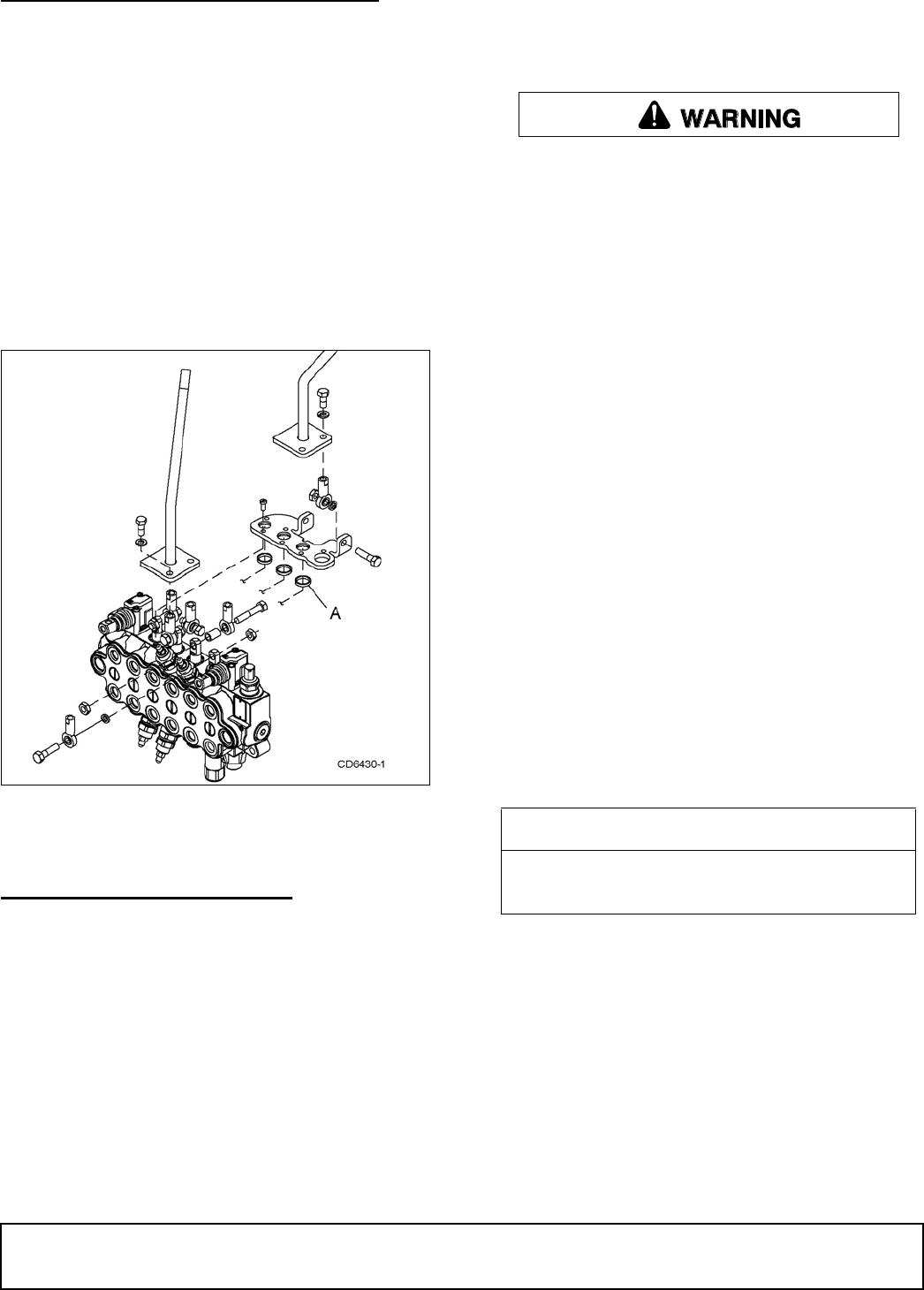

ADJUST CONTROL VALVE LINKAGE

Reconnect control linkage to valve.

Control handles should be positioned as shown.

When completing a maintenance function on the valve,

perform a functional test by placing control handles in

their various positions and make certain the correct

operation occurs corresponding to the decals on the

operator's console. Pay specific attention to the float

position of the boom. Do not operate backhoe if func-

tions differ from the decal.

If the functions differ from the decal, check to make

sure control linkage is correctly installed and check

plumbing schematics to make sure hoses are correctly

connected.

Figure 14. Control Lever Adjustment

BH80-X

HYDRAULIC VALVE REPAIR

Refer to Figure 15.

Valve repair should be accomplished in a clean work

place. Individual components for many of the assem-

blies are not available as repair parts. This will simplify

repair and allow you to replace complete assemblies.

Pressure Settings on Port Relief Valves

Pressure settings on port relief valves are pre-set at

the factory. Although they are adjustable, they must not

be reset in the field using backhoe hydraulic system.

The backhoe pump will separate or crack if system

pressure exceeds the maximum.

Relief valve adjustment requires a test bench and

accurate gauges.

Adjusting System Relief Valve Pressure

Adjustment of system relief pressure must be

done by a qualified, experienced dealership. Incor-

rect adjustment can result in system failures and

serious personal injury.

NOTE: Before changing the pressure setting on the

valve, determine tractor hydraulic system pressure.

Many tractors do not create 2000 psi. If your tractor

does not create 2000 psi, changing the relief valve set-

ting will not improve the backhoe performance.

Place a pressure gauge in the pump pressure line at

the relief valve. When installing pressure gauge, be

sure to use steel fittings that will withstand working

pressure up to 5000 psi.

Remove cap nut (6a). Adjusting screw (6c) has a hex

socket - rotate screw clockwise to increase pressure

and counter-clockwise to decrease pressure.

Start tractor and engage PTO (for pump kits) set throt-

tle at PTO speed. Set system relief valve pressure at

2470 psi. When pressure is adjusted, shut tractor PTO

and tractor off. Replace cap nut (6a) on system valve.

Replacing Port Relief Valves

It is not necessary to remove valve from console to

replace port relief valve cartridges. Remove console

cover and replace them. Be sure you install valve car-

tridges set at the correct pressure. Valves are similar

and can be easily mixed up.

Segment Replacement

Relieve system pressure and remove valve from back-

hoe. Remove tie rods and separate the valve sections.

Replace defective sections as necessary. Make sure

you install two spacers between each section of each

tie rod. Note the location of O-rings (9 & 10). They must

be placed in the location between valve sections as

shown in Figure 15.

When assembling valve sections, use care when torqu-

ing nuts on tie rods. This must be done in steps - that is

to say, gradually increasing the tightening torque up to

Port Relief Valve Pressure Setting

4AA 2470 psi

4BB 2610 psi