User manual W3532

- 17 -

hinge arm from the cutting mechanism and release the

draw of the arm. Draw out the cutting mechanism to

the left or right side. The assembly is performed in

the opposite procedure.

Adjustment of the height of the cutting

mechanism

When adjusting the cutting mechanism it is necessary to:

1. place the self-moving rotary cutter on a plain area

2. set the cutting mechanism to the lower position

3. loosen the arresting bolts of the draw bars of the front

hinge of the cutting mechanism

4. set the cutting mechanism into the required position

5. tighten the bolts of the draw bars of the front hinge

Replacement of driving belts

The power from the engine to the cutting mechanism is

transferred by means of the V-belt and the belt with double-

sided teeth. The driving belts must be replaced as soon as they

start to show symptoms of wear. Use only original belts!

Adjustment of the driving belt Engine – cutting

mechanism

The belt is permanently fastened with a spring-biased pulley

and, therefore, no additional adjustment or tensioning is

necessary.

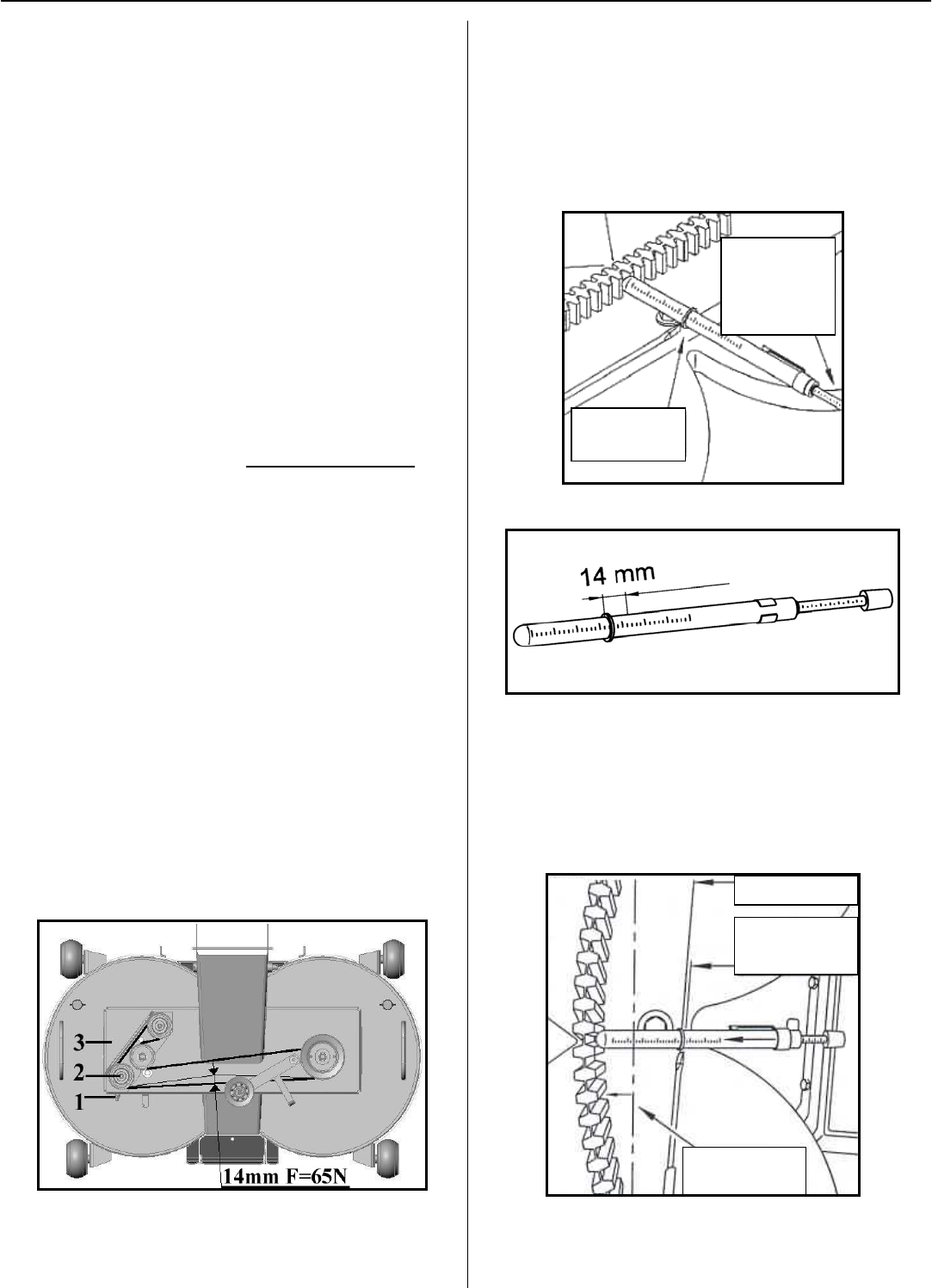

Adjustment of the driving belt for blade drives,

Fig.16

The tensioning of this belt is performed by the adjustment of

the nut (1) after the loosening of the bolt of the pulley (2) on

the lower side of the board (3).

A correctly tightened belt has a bend of 14 mm (in the middle

of the distance between the toothed belt pulley) with the

loading 65 N. After the tightening of the belt, tighten the

pulley bolt (2). After tightening, check the value of the

tightening of the belt.

Fig.16

Method of measurement and TENSION

TESTER No. 7401-0076 (possible to deliver on an

order basis)

Place the measuring preparation on the cover Fig.17 so that the

measuring device is in contact with the toothed belt – without

pressure. Shift the O ring up to the cover. Re-adjust the smaller

O-ring to the beginning of the power scale, Fig.17. Re-adjust

the greater O-ring to the required value by 14 mm, Fig. 18.

Fig.17

Fig.18

Catch the measuring instrument at the handle (read handle) and

press against the toothed belt for as long as the O-ring is in

contact with the wall of the cover Fig.19 and 20. Remove the

measuring instrument and ascertain to which value the O-ring

was shifted on the scale in N (v kg). In the case of the correct

tightening of the toothed belt on measuring route 14 mm, you

will achieve loading of 65 N (6.5 kg).

Fig.19

Measuring

ring must be

in contact with

the tested

body

Reference

point

Reference point

Move O-ring to the

reference point

Measurement

value