User manual W3532

- 14 -

empty, wash and attach it again on order to be dried very

quickly. If there are any reminders of grass on the walls of the

bag, it is necessary to clean it so that the material can breathe.

Wash the plastic parts of the body with water and a sponge

dipped in washing detergent and pay attention so that the

engine and parts of the electrical installation are not in

contact with water.

Fig.12

Never use a high-pressure cleaner or aggressive detergent

for washing the body, engine and electric actuator.

If these principles are not complied with, there is the risk

of the expiration of the warranty.

Storage and not using the machine for long

periods

Store the self-moving rotary cutter in a dry place protected

against atmospheric influences and cover it, if possible. If the

machine will not be used for a long time (longer than one

month) it is necessary to disconnect the red cable from the

accumulator and follow the instructions in the Manual for the

engine). Emptying the fuel tank

Regularly check that the voltage in the accumulator has

not decreased below 12V. Charge it, if necessary

5. Maintenance

Important!

With respect to the protection of the environment, take

care to prevent the escape of oil, fuel or other harmful

substances.

All repairs, maintenance and treatment of the machine is

to be performed when the engine is not active when the

ignition key is removed.

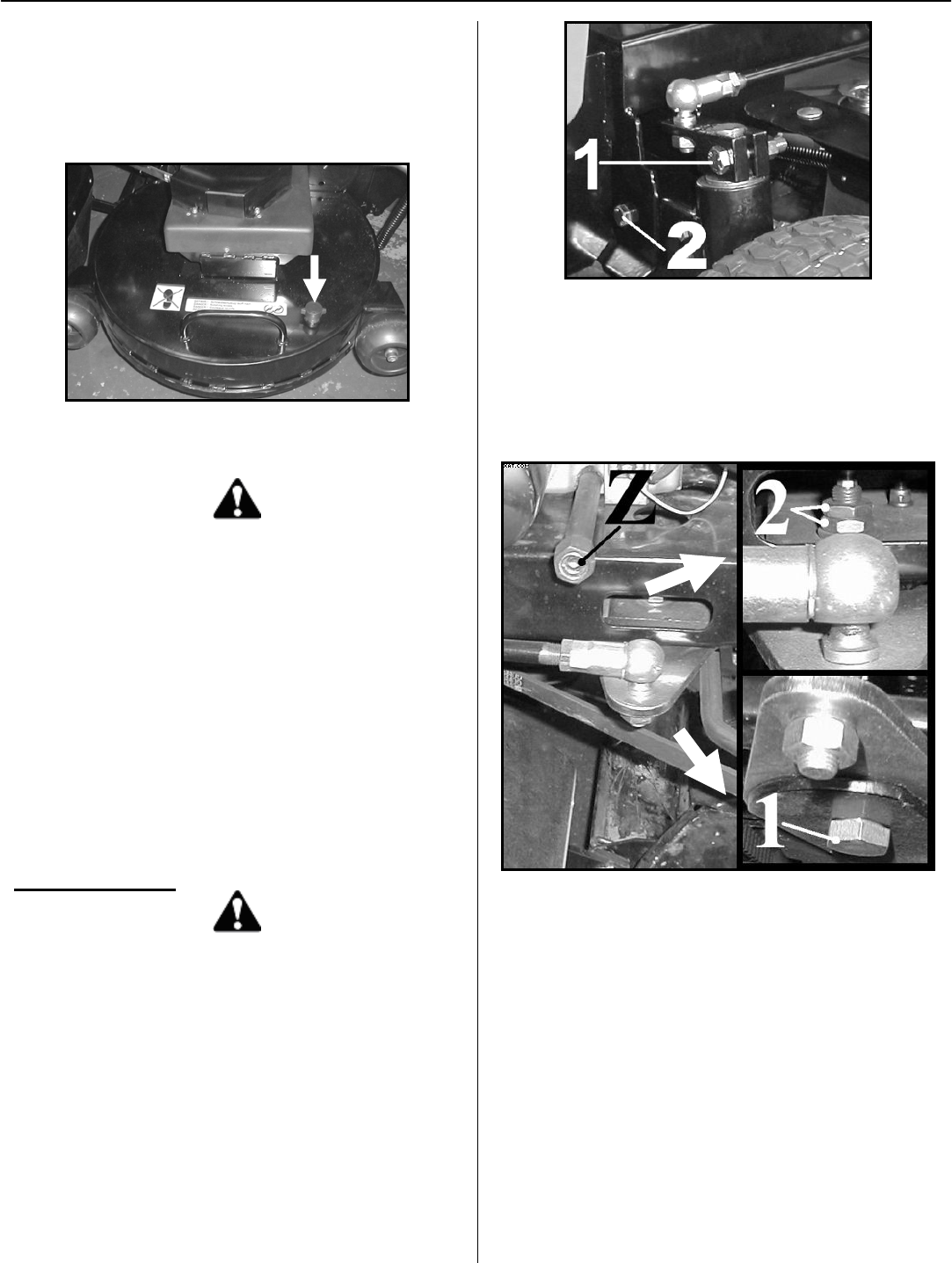

Front axle - Fig.13

After five hours of operation, tighten the bolt (1) on the arm of

the left vertical pin. The bolts (2) serve for setting the

clearance of the front axle in the frame.

Fig.13

Gearing – Fig.14

After 5 hours of operation of the machine, adjust the free

gearing by turning the accessible pin downward from the

machine. Using the pin (1) it is possible to turn after loosening

the two nuts (2). After setting the clearance of the nut, fully

tighten.

Fig.14

Engine

Proceed according to the instructions of the Service and

Maintenance Manual (air cleaner, fuel cleaner, replacement of

oil, cleaning of ignition sparks, etc.).

The engine oil is discharged into the prepared vessel by

unscrewing cap “Z” on the discharging hole Pic.14. During

the replacement or discharging of oil always hold the neck

of the discharging tube with an hexagonal wrench, so as not

to loosen the tube when removing the cap! Otherwise there is

the risk of the unwanted escape of oil!

Electromagnetic clutch – Fig.15

The clearance between the rotor and the body of the

electromagnetic clutch must be within the range 0.35-0.5 mm

(the higher value is for summer operation). The adjustment is

performed by tightening (loosening) the 3 bolts position 1

Fig.15.