Rev. A

Workman MD/MDX Drive TrainPage 5 -- 15

Driven Clutch Service (Serial Number Below 310000000)

NOTE: Vehicles with a serial number below 310000000

are equipped with a Comet brand driven clutch.

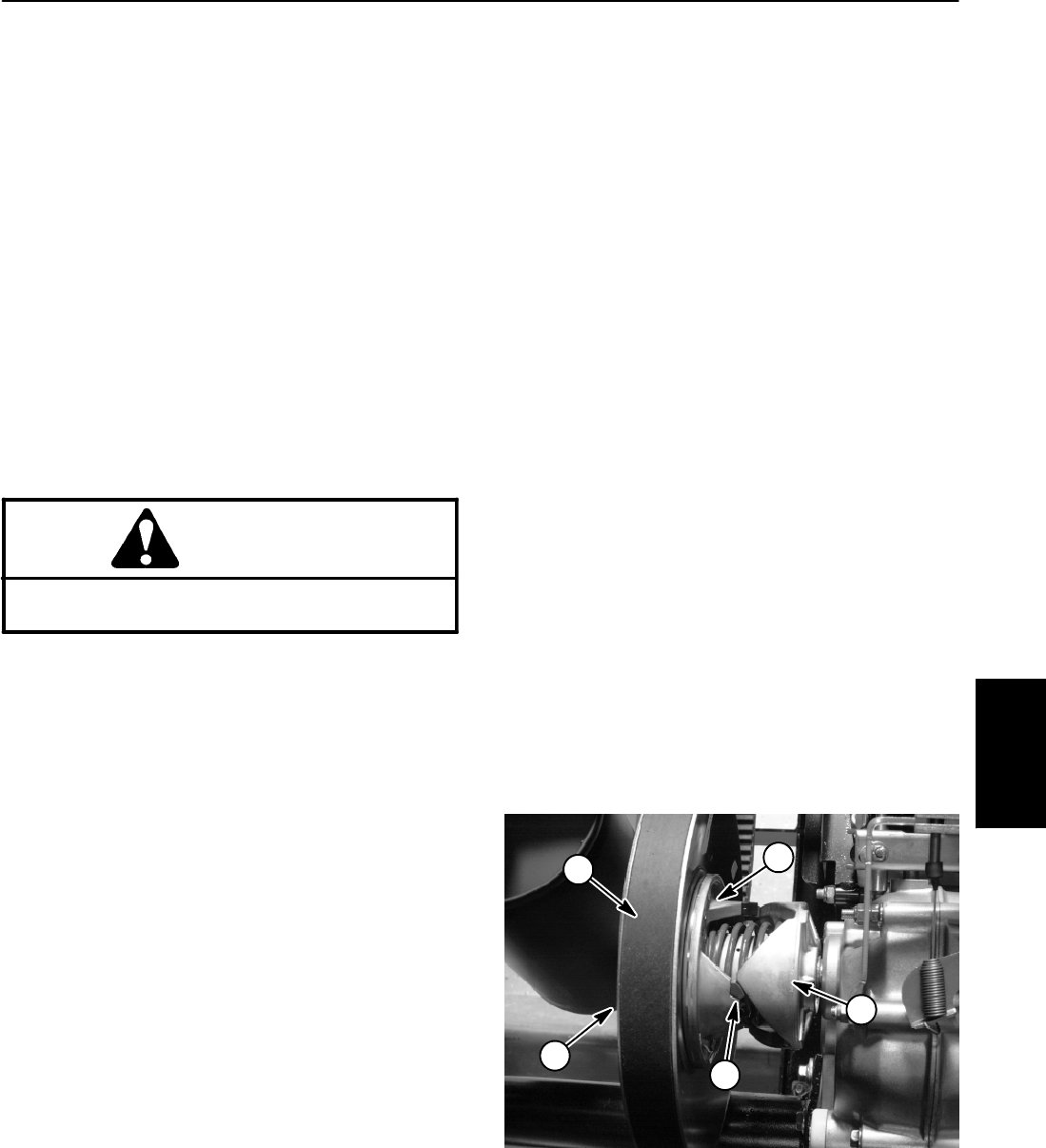

Ramp Button Replacement (Fig. 21)

1. Park vehicle on a level surface, stop engine, set

parking brake and remove key from the ignition switch.

Raise and support cargo box.

2. Remove drive belt from the driven clutch (see Ser-

vice Drive Belt in Service and Repairs section of Engine

Chapter).

3. Turn fixed and moveable sheaves in opposite direc-

tions so button is separated sufficiently enough from the

ramp to allow removal.

4. Place small block of wood between the outer ramps

to keep the ramps apart.

CAUTION

To prevent burns, hold a llen wrench with locking

pliers when heating allen wrench.

5. Clamp long end of a 2 mm allen wrench with locking

pliers. Heat short end of the allen wrench until it is red

hot.

6. Insert hot end of the allen wrench into the button so

it melts around the end of the wrench. Hold wrench in

place until the button hardens.

7. Pull and twist on the allen wrench to remove the but-

ton from the ramp.

NOTE: If the new button is difficult to install, sand its

mounting tab as necessary. If the button is loose, apply

Loctite #242 (or equivalent) on its mounting tab.

8. Install new button to ramp. Push button in straight

with a screw driver by prying against the ramp.

9. As needed, remove and install remaining buttons.

10.Carefully remove block of wood that was placed to

keep the clutch ramps apart.

11.Install drive belt to the driven clutch.

12.Lower and secure cargo box.

Check Driven Clutch Spring Tension (Fig. 21)

1. Park machine on a level surface, stop engine, set

parking brake and remove key from the ignition switch.

Raise and support cargo box.

2. Place transaxle in gear to prevent the fixed sheave

from moving.

3. Remove drive belt from the driven clutch.

IMPORTANT: U se protective strips of soft metal

when clamping the moveable sheave with locking

pliers to prevent damage to the sheave.

4. Clamp moveable sheave with locking pliers.

5. Measure spring torsion.

A. Pull scale tangentially to the outer diameter of the

moveable sheave.

B. When the button on the ramp of the moveable

sheave is 0.125 inch (3.18 mm) from the ramp of the

fixed sheave, read the scale.

C. The reading should be 16 to 20 lbf (71 to 89 N).

6. If the above specification is not met, replace the driv-

en clutch.

7. Install drive belt to driven clutch.

8. Lower and secure cargo box.

1. Moveable sheave

2. Ramp (fixed cam)

3. Button

4. Fixed sheave

5. Drive belt

Figure 21

3

2

1

5

4

Drive Train