Workman MDX Page 3 -- 7 Briggs & Stratton Gasoline Engine

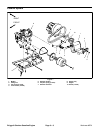

Removal (Fig. 5)

1. Make sure machine is parked on a level surface with

the engine OFF.

2. Raise cargo box and support with prop rod.

3. Thoroughly clean junction of intake hose and carbu-

retor adapter on engine and air cleaner assembly.

4. Remove air cleaner components as needed using

Figure 5 as a guide. Discard any removed gaskets and

clean gasket mating surfaces.

Installation (Fig. 5)

IMPORTANT: Any leaks in the air filter system will

allow dirt into engine and will cause serious engine

damage. Make sure that all air cleaner components

are in good condition and are properly secured dur-

ing assembly.

1. Assemble all removed air cleaner components using

Figure 5 as a guide.

A. Install new gaskets (items 10 and 14) if they were

removed.

B. If flange head screws (item 9) were loosened or

removed, torque screws from 60 to 65 in--lb (6.8 to

7.3 N--m).

C. Make sure that air cleaner vacuator valve is

pointed toward ground and slightly toward engine af-

ter assembly.

D. Make sure to secure intake hoses with hose

clamps.

2. Lower and secure cargo box.

Figure 6

1. Air cleaner

2. Carburetor adapter

3. Breather hose

4. Intake hose

3

1

2

4

Briggs & Stratton

Gasoline Engine