Rev. B

Workman MD/MDXPage 6 -- 28Electrical System

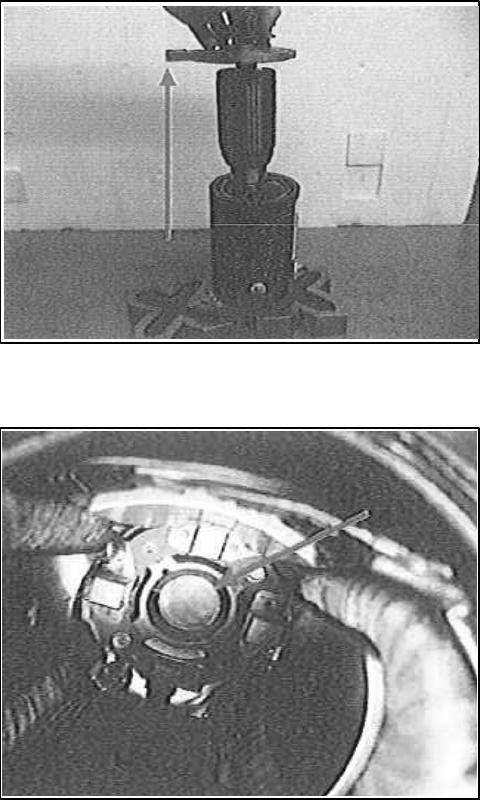

4. Pull drive head end along with attached armature

from the frame housing.

Figure 35

5. Position the motor so the commutator end head is fa-

cing upwards and remove the two (2) screws thatsecure

the c ommutator end head. Lift commutator end head

from frame housing.

6. Locate and retrieve wave washer from between

armature and commutator end head.

IMPORTANT: Use clean, dry, lint--free rags when

cleaning the starter/generator. When using com-

pressed air, air should be filtered and should not ex-

ceed 15 PSI (103 kPa).

7. Clean inside of the frame housing with compressed

air.

IMPORTANT: Remove bearings from armature only

if they are to be replaced. Use proper b earing re-

moval and installation tools.

8. Clean bearings using a clean cloth. Inspect bearings

for damage. Replace both bearings if either bearing

meets any of the following conditions:

A. Bearings do not spin smoothly, are noisy when ro-

tated o r have excessive end or axial play.

B. The bearing balls or rolling surfaces are pitted or

worn.

C. The bearings are rusted, worn, cracked or show

abnormal color due to overheating.

NOTE: Individual components in the frame housing are

not available separately. Replace housing or complete

starter/generator if damage exists in frame and field as-

sembly.

Figure 36