INTELLI-JET CLEANING PROCEDURE

If you experience a sticky rotational jet, perform the following

cleaning procedure. In most of these cases debris is present in the

jet bearings and must be cleared to achieve proper operation. Note:

This procedure is considered normal maintenance for this type of jet.

Procedure

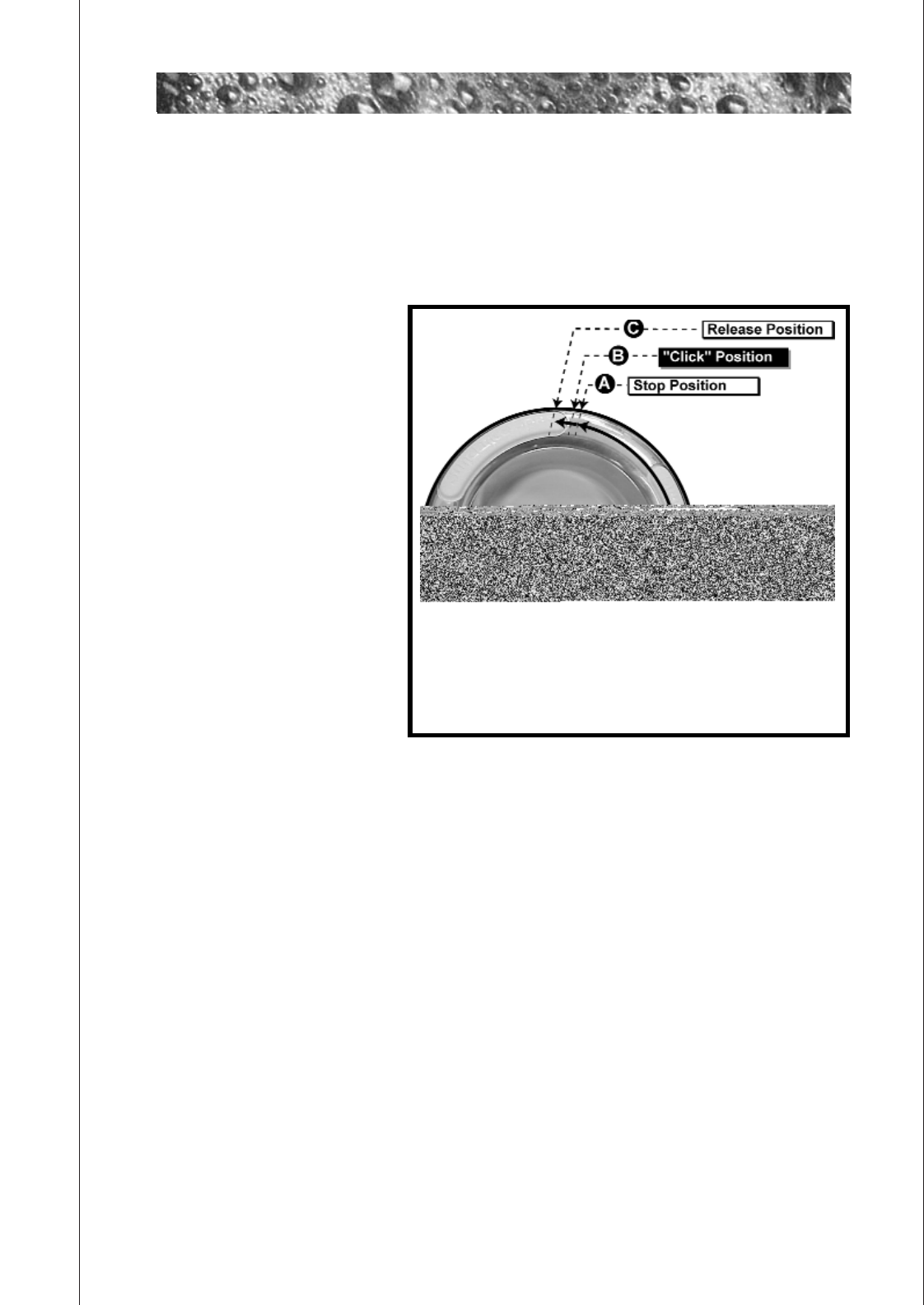

1. Remove jet internal

from hot tub wall

fitting by placing your

hand around the

outer jet adjustment

ring and rotating it

counterclockwise

(fig. 1). Rotate jet

adjustment ring until

it stops at position

(A). Use additional

force at position (A)

to continue rotation

until you feel a “click”

at position (B); then

feel the internal

release at position

(C). It may seem like

your are overtorquing

the jet internal between positions (A-B), however, additional force

is necessary at position (A) to unlatch its retaining mechanism

from the wall fitting.

2. Fill a clean bucket with tap water and immerse jet internal. Rotate

submersed jet internal’s nozzle in a circular motion while moving

it back and forth allowing water to flow through both ends of the

jet. This motion allows slow moving water to wash back through

the jet bearing and dislodge any debris that might be lodged in

the bearing. Clean each jet internal for approximately 1 to 2

minutes twice a year, or when a particular jets rotation appears

sluggish, jerky, or obstructed.

3. Reinstall jet internal by inserting it in any jet opening of the same

jet type. Rotate the jet internal clockwise with light pressure until

your feel the retaining mechanism “snap” in place. The jet’s

nozzle should rotate freely to the left or right using only fingertip

pressure. If jet rotation appears sluggish or obstructed at this

time, repeat steps 2-3 until condition clears. If condition persists,

contact dealer for technical support.

Page 26