24

Section 3 - OPERATING INSTRUCTIONSSection 5 - ADJUSTMENTS & REPAIR

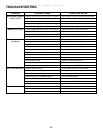

5.6 TRACKING ADJUSTMENT

If the machine does not track straight when the Motion

Control Levers are in the maximum forward speed

position, perform the following adjustment. Rear tire

pressure must be set to 12 PSI before making this

adjustment.

1. Loosen bolts that secure adjustment plates and

slide plates all the way forward. Retighten bolts.

2. Start machine and drive in smooth flat open area at

maximum forward speed.

3. If machine tracks to the right, loosen bolts that

secure the left adjustment plate. Move plate rearward

to slow the left wheel. Retighten bolts.

4. If machine tracks to the left, loosen bolts that

secure the right adjustment plate. Move plate rearward

to slow the right wheel down. Retighten bolts. See

Figure 5.12.

5. Drive machine again. Repeat adjustment as neces-

sary until machine tracks straight.

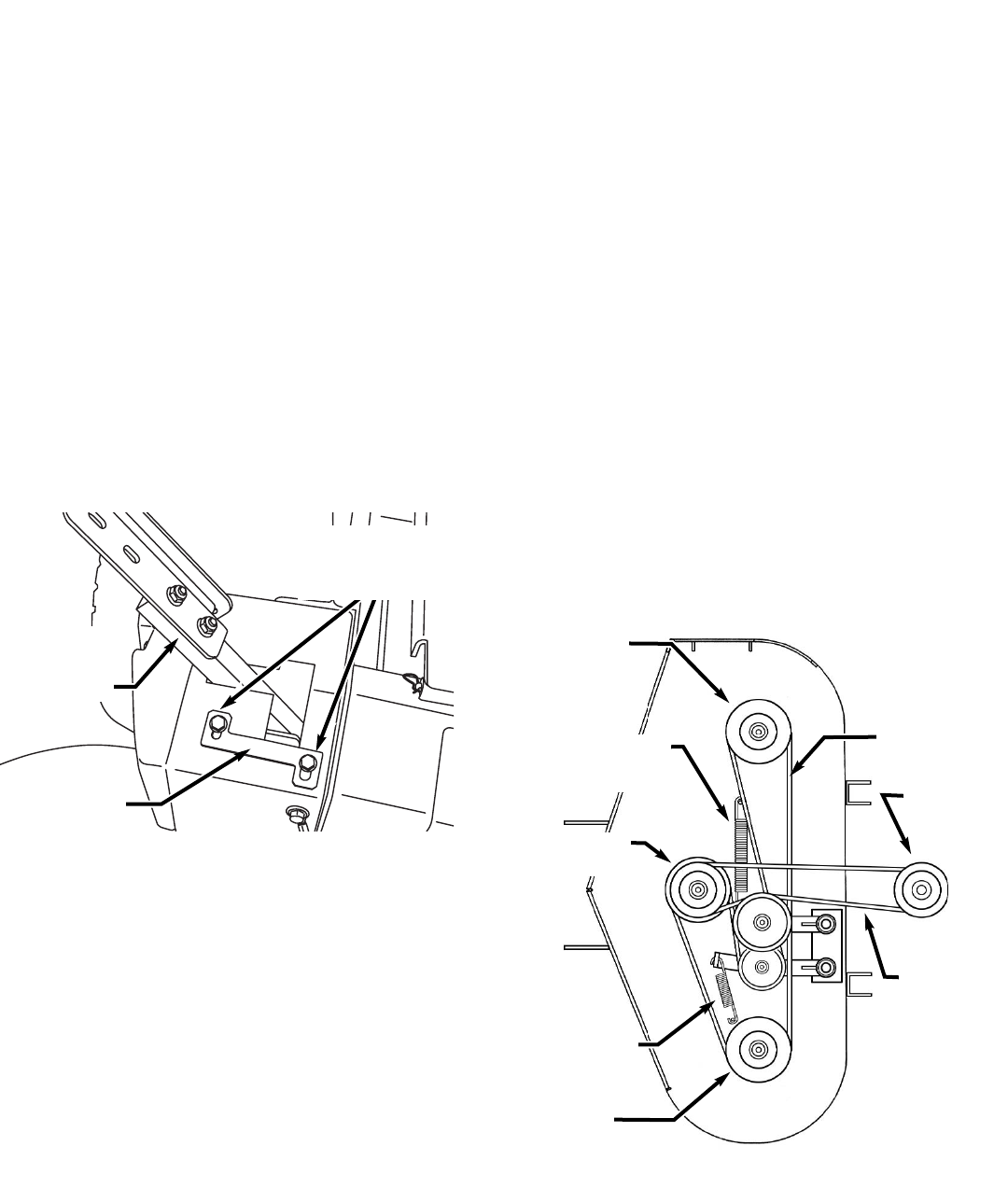

5.7 MOWER DRIVE BELT REPLACEMENT

Inspect mower drive belt. Replace belt if it shows signs

of excessive wear, damage and/or is broken.

5.7.1. BELT REMOVAL

1. Remove power unit footrest.

2. The engine to deck belt must be removed before

the deck belt can be removed. Remove engine to

deck belt. NOTE: Disconnecting engine to deck belt

idler spring may assist in removing belt.

3. Disconnect deck belt tension spring.

4. Remove old deck belt. Note the belt routing. See

Figure 5.13.

5.7.2. BELT REPLACEMENT

1. The deck belt must be installed first and the engine

to deck belt installed last.

2. Route deck belt around blade pulleys and idler pul-

ley in the same position as old belt was removed. See

Figure 5.13.

3. Reconnect idler pulley spring.

4. Reinstall engine to deck belt. Reconnect idler

spring if disconnected.

5. Reinstall power unit footrest.

FIGURE 5.12

FIGURE 5.13

LEFT

PULLEY

CENTER

PULLEY

ELECTRIC

CLUTCH

ENGINE TO

DECK BELT

BELT ROUTING

ENGINE TO

DECK BELT

IDLER SPRING

ADJUSTMENT

PLATE

RIGHT SIDE

MOTION

CONTROL

LEVER

LOOSEN BOLTS,

SLIDE PLATE TO

MAKE MACHINE

TRACK STRAIGHT

RIGHT

PULLEY

DECK BELT

DECK BELT

IDLER SPRING