23

Section 3 - OPERATING INSTRUCTIONSSection 5 - ADJUSTMENTS & REPAIR

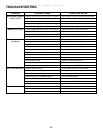

5.3 TRACTION BELT TENSION

The traction drive belt tension does not require adjustment.

If the belts are slipping, they will have to be replaced.

5.4 TRACTION BELT REPLACEMENT

1. Remove clutch to deck belt. Refer to Section

“Mower Drive Belt Replacement”.

2. Turn hex nuts out to the end of eyebolt, reducing

spring tension. See Figure 5.9.

3. Remove hardware securing anti-rotation bracket to

frame. See Figure 5.9. NOTE: Do not remove anti-

rotation bracket from clutch.

4. Disconnect the electric clutch from main wire har-

ness. See Figure 5.9.

5. Remove traction belts from around engine pulley

and hydro pumps.

6. Install new belts, routing around engine pulley and

hydro pump pulleys. See Figure 5.10.

7. Reconnect electric clutch to main wire harness.

8. Reinstall anti-rotation bracket to frame and tighten

hardware securely.

9. Run hex nuts all the way to the end of the threads

on the eyebolt. See Figure 5.9.

10. Reinstall electric clutch to deck belt onto electric

clutch.

FIGURE 5.9

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine running. STOP engine. STOP

blades. Set brake. Remove key. Remove spark plug

wires and secure away from spark plugs. Engine and

components are HOT. Avoid serious burns, allow suf-

ficient time for all parts to cool.

!

!

FIGURE 5.11

INSERT FEELER GAUGE.

GAP SHOULD BE .015

ROTATE NUTS IN OR

OUT TO ACHIEVE

CORRECT GAP

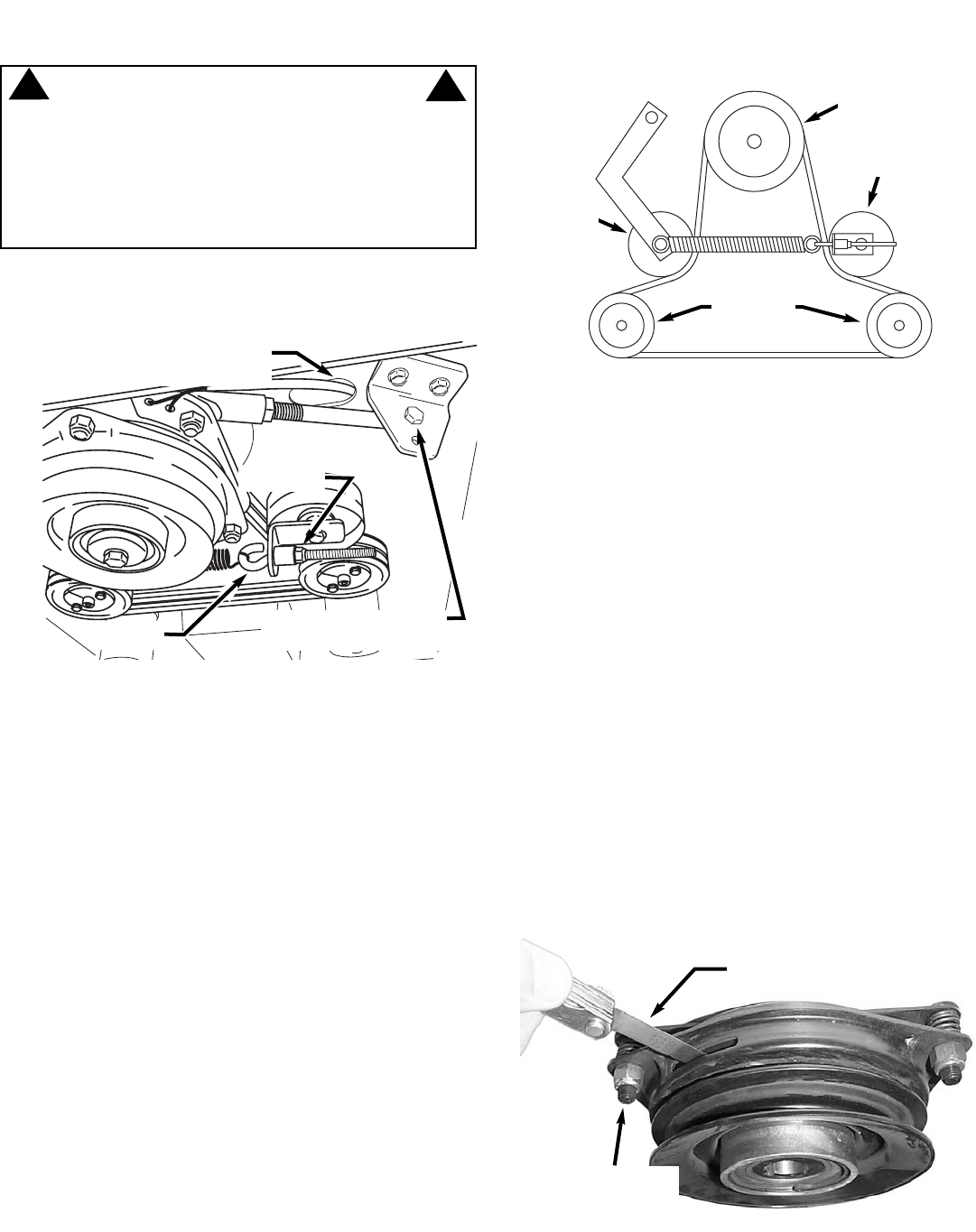

5.5 BLADE BRAKE/ELECTRIC CLUTCH ADJUSTMENT

The blade switch engages the electric clutch when

pulled out to the "ON" position. When the blade switch

is in the "ON" position the cutting blade(s) are

engaged. The blade switch disengages the electric

clutch when the blade switch is pushed in to the "OFF"

position. When the blade switch is in the "OFF" posi-

tion the cutting blade(s) are disengaged. The electric

clutch is adjustable. The blades should stop rotation in

7 seconds or less. If the electric clutch fails to stop the

blades rotation in 7 seconds, adjustment is necessary.

1. Insert a feeler gauge into the three slots on the

electric clutch.

2. Check gap through all three slots in the side of the

clutch. The gap should be set at .015.

3. If gap is incorrect rotate nuts in or out to achieve the

correct gap. See Figure 5.11.

NOTE: Electric Clutch is shown removed from the

machine. Removal is not necessary for adjustment.

FIGURE 5.10

(View looking up)

ENGINE PULLEY

(ABOVE CLUTCH)

STATIONARY

IDLER

TENSIONING

IDLER

PUMP

PULLEYS

TRACTION

BELT

ROUTING

HEX NUTS

REMOVE ANTI-ROTATION

BRACKET FROM FRAME

DISCONNECT CLUTCH FROM

MAIN WIRING HARNESS

EYEBOLT