Operation Section 4-7Turf Flex 08-01

OPERATION

© 2004 Alamo Group Inc.

OPERATION

WARNING! Either failure can allow the Driveline to come loose from the tractor which could cause bodily

injury to the operator or others in the vicinity along with expensive damage to the tractor and/or

Cutter.

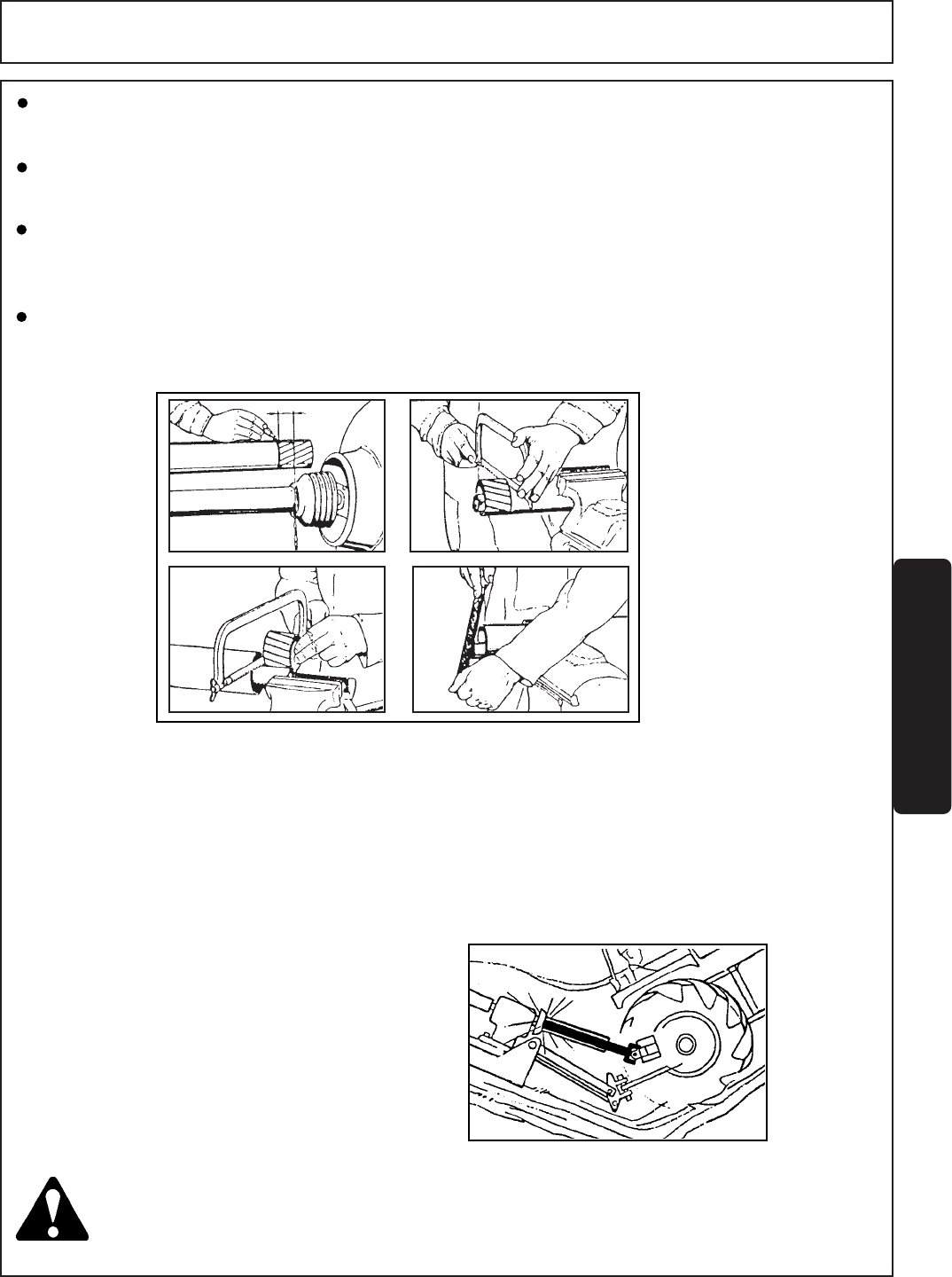

Driveline bottom out.

FIGURE 9

With the PTO NOT TURNING, slowly drive the tractor with mower attached through sharpest turn possible

and watch shaft movement.

With PTO NOT TURNING, slowly drive the tractor with mower attached through the most severe terrain

conditions expected and watch Shaft movement.

Check position which places driveline at maximum extended length and at maximum compressed length.

Maximum extended length must always maintain at least 10 inches of profile tube engagement. Maximum

compressed length should always maintain 1-9/16 clearance; if not shorten driveline as shown in Fig 8.

If driveline cannot be shortened and still maintain 10 inches of tube engagement then the operator should

note test so he can recognize the terrain conditions that might cause the problem and avoid possible dam-

age by disconnecting driveline from tractor.

SPECIAL INSTRUCTIONS FOR ROUGH TERRAIN OPERATIONS

When crossing ditches with steep banks or going up sharp inclines, it is possible to “bottom out” the Driveline that

connects the tractor PTO to the Gearbox on mower.

Note: To bottom out means that the Inner Shaft has penetrated into the Outer Housing to its maximum depth until

the Assembly becomes solid - it can shorten no more. See Figure 9.

If this happens, it can cause serious damage to the tractor PTO by pushing the PTO into the tractor and through

the Support Bearings or downward onto the PTO Shaft, breaking it off.

FIGURE 8

1-9/16