15

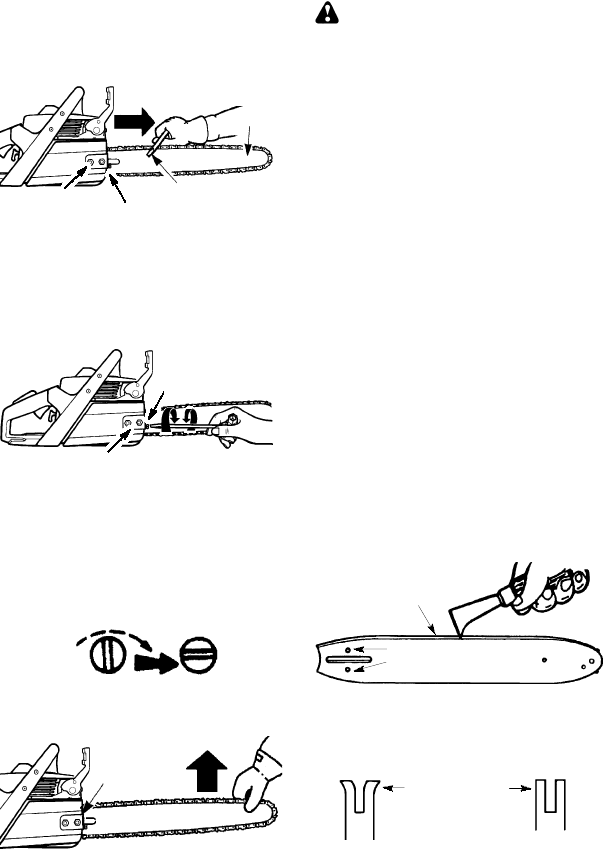

1. Use the screwdriver end of the

chain adjustment tool (bar tool) to

move chain around guide bar to

ensure kinks do not exist. The

chain should rotate freely.

Chain Adjustment

Tool

(Bar Tool)

Guide

Bar

Chain Brake

Nuts

Adjusting

Screw

2. Loosen chain brake nuts until they

are finger tight against the chain

brake.

3. Turn adjusting screw clockwise

until chain solidly contacts bottom

of guide bar rail.

Adjusting screw

Chain Brake Nuts

4. Using bar tool, roll chain around

guide bar to ensure all links are in

bar groove.

5. Lift up tip of guide bar to check for

sag. Rel ease tip of guide bar, then

turn adjusting screw

1

/

4

turn clock-

wise. Repeat until sag does not

exist.

Adjusting Screw --

1

/

4

Turn

6. While lifting tip of guide bar, tighten

chain brake nuts securely with the

bar tool.

Chain Brake

Nuts

7. Use the screwdriver end of the bar

tool to move chain around guide

bar.

8. If chain does not rotate, it is too

tight. S lightly loosen chain brake

nuts and loosen chain by turning

the adjusting screw counterclock-

wise. Retighten chain brake nuts.

9. If chain is too loose, it will sag be-

low the guide bar.

DO NOT

operate

the saw if the chai n is loose.

W ARNING:

If the saw is operated

with a loose chain, the chain could

jump off the guide bar and result in se-

rious injury.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A

dull chain makes a sawdust powder

and cuts slowly. See

CHAIN SHARP-

ENING

in the

SERVICE AND ADJUST-

MENTS

section.

CHECK GUIDE BAR

Conditions which require guide bar

maintenance:

S

Saw cuts to one side or at an angl e.

S

Saw h as to be forced t hrough t he cut.

S

Inadequate supply of oil to bar/chain.

Check the condition of guide bar each

time chain is sharpened. A worn guide

bar will damage the chain and make

cutting difficult.

After each use, ensure

ON/ST OP

switch is in the

STOP

position, then

clean all sawdust from the guide bar

and sprocket hole.

To maintain guide bar:

S

Move

ON/ST OP

switch to

STOP.

S

Loosen and remove chain brake

nuts and chain brake. Remove bar

and chain from saw.

S

Clean the oil hol es and bar groove

after each 5 hours of operation.

RemoveSawdust From

Guide Bar Groove

Oil Holes

S

Burring of guide bar rails is a normal

process of rail wear. Remove these

burrs with a flat file.

S

When r ail top is uneven, use a flat file

to r estore square edges and sides.

CorrectGrooveWorn Groove

File Rail Edges

and Sides

Square

Replace guide bar when t he g roove is

worn, the guide bar is bent or cracked,

or w hen excess heating or burring of the

rails occurs. If r eplacement is necessary,

use only the guide bar specified for your

saw in the repair par ts list o r on the de-

cal located on the chain saw.

CHECK FUEL MIXTURE LEVEL

S

See

FUELING ENGINE

under the

OP-

ERATION

section.