t tl i i i i i

SERVICE AND ADJUSTMENTS

ii i ii i

CARBURETOR ADJUSTMENTS

.Ca_uretor adjustment is critical and if done imprope_ can permanently damage the engine as well as.the car-

- Durezor. vrease reaa all instructions and consult the Troubleshooting section of this manual before beginning

this process.

If engine does not start, it may be flooded. If in doubt,

read the section on flooded engine in the startingsection

of this manual priorto beginning any adjustments.

If you are unsure about adjustingthe carburetor or expe-

rience any problem while attemptingthis procese, please

call the 1-800 number listed on the front cover of th s

manual for further assistance.

The carburetor has been adjusted at the factory for sea

level conditions. Adjustments may become necessary if

, the unit:is used at significantly:higheraltitudesor i:fyou

notice any of the Tollowing conditions:

•* Bladeor trimmer head moveswhen the engine runs at

• Turn idle speed screw ("3")clockwise1/2 turn.

• Start the engine and operate for ten (10) minutes to

warm up. Go to "Adjusting Procedure.

ADJUSTING PROCEDURE

Engine operating speeds: Maximum operating speed:

11,000 RPM.

IDLE SPEED ADJUSTMENT

: Allowthe warm engine to idle.

Adjust the Idle Speed Screw untilthe engine continues

.... to run without stalling and without the, blaoe _or semi-

automatichead turning.

- Turn screw clockwise to increase engine speed if

enginestalls ordies.

idle speed. See =idle Speed Adjustment." _ . .

_ Engine will not idle. See Idle Speed Adjustment"and - lurn screw counterclockwise ro slow engine Oown

?LowSpeedMixture :AdjualmenL_ .... . an_,ortokeep.:thebladeorb'lmmerh_.d.fro.m_tumi.ng_

Engine dies or hesitates when it-should accelerate:See..- :. r_omrther adjustments are necessary _ place or ram-

=Acceleration Adjustment." mer head does not turn at idle speed and if peffor-

• Loss of cutting power which is not corrected by air filter .... mance is satisfa_ory.

_ cisan!ng. See =High Speed: Mixture Adjustment."

NOTE_ Ifthe Cutting Attachment rotates during idle; turn

the idlespeed adjusting screw ("T")counterclockwiseuntil

the Cutting Attachment stops.

_ CAUTION:

MAKE ALL CARBURETOR ADJUST-

MENTS WITH TRIMMER HEAD ATTACHED.

_0_ NOT ATTEMPTTO ADJUST CARBURE-

TOR WITH BLADE ATI'ACHED DUE TO DIF-

RCULTY OF PROPERLY SETTING CARBU-

RETOR. SEVERE ENGINE DAMAGE

COULD OCCUR.

_ WARNING:

MAKE CARBURETOR ADJUSTMENTS

WITH THE LOWER END SUPPORTED TO

PREVENT TRIMMER HEAD FROM CON;

TACTING ANY OBJECT. HOLD UNIT WITH

YOUR HAND.

THE TRIMMER HEAD WILL BE SPINNING

DURING MOST OF THIS PROCEDURE.

WEAR YOUR PROTECTIVE EQUIPMENTAND,

OBSERVE ALL SAFET_-_PRECAU:TIONS_ ...

IN "LOW SPEED MIXTURE:ADJUSTMENT,".

RECHECK IDLE SPEED,AFTER EACH,

ADJUSTMENT.THE TRIMMER HEAD MUST

; , • , NOT MOVE AT IDLE SPEED.

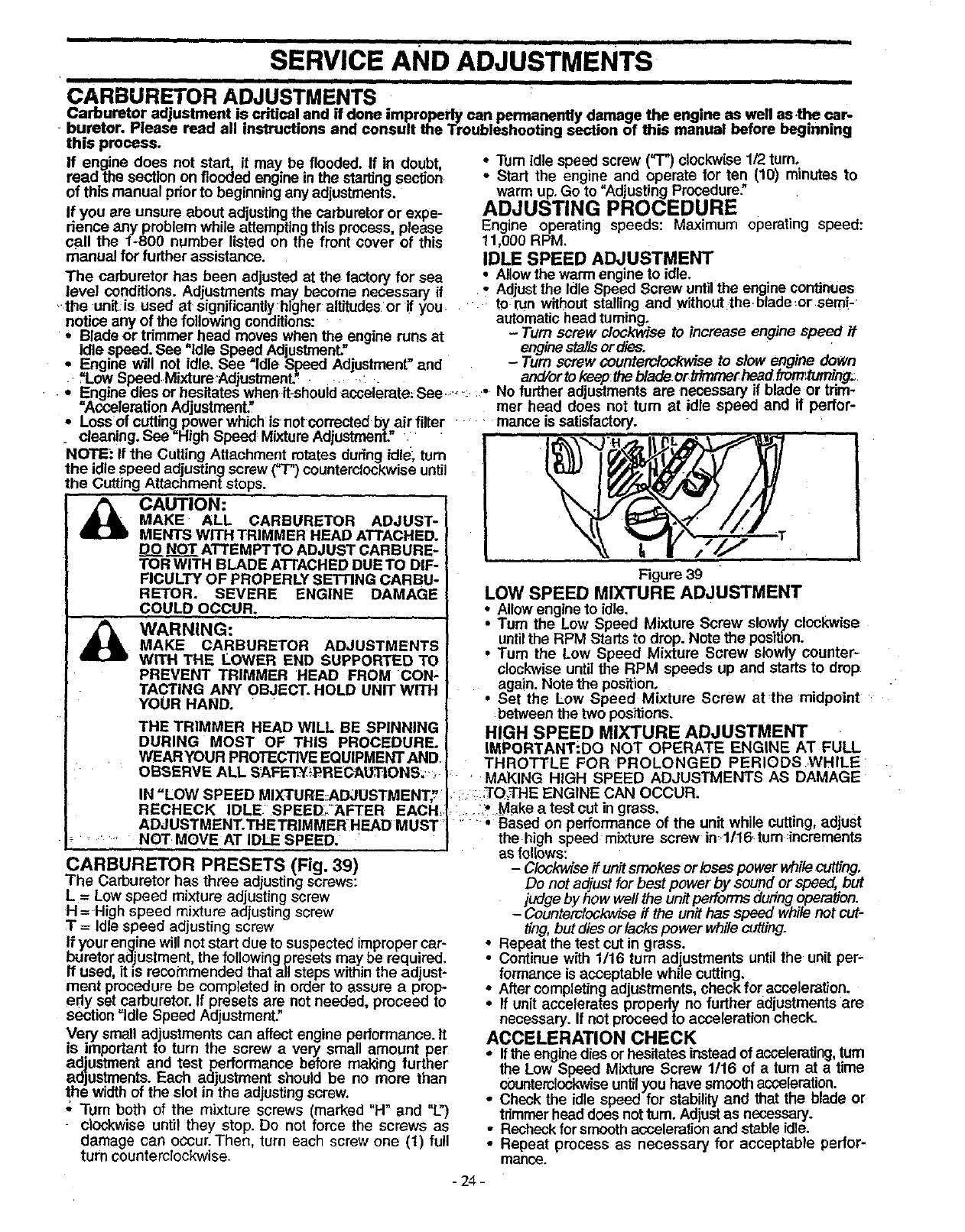

CARBURETOR PRESETS (Fig. 39)

The Carburetor has three adjustingscrews:

L = Low speed mixture adjusting screw

H= High speed mixture adjustingscrew

T = Idle speed adjusting screw

If your engine willnot start due to suspected improper car-

bt.iretoradjustment, the following presets may be required.

If used, it is recommended that all steps within the adjust-

ment procedure be completed in order to assure a prop-

edy set carburetor. If presets are not needed, proceed to

section =Idle Speed Adjustment."

Very small adjustments can affect engine pedorrnance. It

is important to turn the screw a very small amount per

ad._ustmentand test performance before making further

aojustments. Eacn adjustment should be no more than

the widthof the slot in the adjusting screw.

° Turn both of the mixture screws (marked "H" and "L")

- clockwise until they stop. Do not force the screws as

damage can occur. Then, turn each screw one (t) full

turn counterclockwise.

Figure 39

LOW SPEED MIXTURE ADJUSTMENT

• Allow engine to idle.

•Tum the Low Speed Mixture Screw slowly clockwise

• untilthe RPM Starts to drop. Note the position.

Turn the Low Speed Mixture Screw slowly counter-

clockwise untilthe RPM speeds up and starts to drop

again. Note the position.

• Set the Low Speed Mixture Screw at :the midpoint

between the two pos_ons.

HIGH SPEED MIXTURE ADJUSTMENT

IMPORTANT'DO NOT OPERATE ENGINE AT FULL

THROTTLE FOR PROLONGED PERIODS WHILE:

• MAKING HIGH SPEED ADJUSTMENTS AS DAMAGE

,_; ,TO,THE ENGINE CAN OCCUR.

: '• Make a test cut in grass.

--,, Based on performance of the unit while cutting, adjust

the high speed mixture screw in 1116 turn,increments

as follows:

- Clockwise if unit smokes or loses power while cutting.

Do not adjust for best power by sound or speed, but

judge by how well the unit performs during,operation.

- Counterclockv_se if the unit has speea whilenot cut-

ting, but dies or lacks power whilecutting.

: Repeat the test cut in grass.

Continue with 1/16 turn adjustments until the unitper÷

formance is acceptable while cutting.

• After completing adjustments, check for acceleration.

• If unit accelerates properly no further adjustments are

necessary. If not proceed to acceleration check.

ACCELERATION CHECK

, Ifthe engine dies or hesitates insteadofsccelerating, turn

the Low Speed Mixture Screw 1/16 of a turn at a time

counterclockwise until you have smooth acceleration.

• Check the idle speed for stability and that the blade or

trimmer head does not turn. Adjust as necessary.

• Recheck for smooth acceleration and stable idle.

• Repeat process as necessary for acceptable perfor-

mance.

- 24 -