27

each appliance. Adjust thermostat so appliance

will operate continuously.

e) Check the pressure at a pressure tap located 12

in. above the bottom joint of the first vertical vent

pipe. Pressure should be anywhere between -.01

to -.08 in. WC.

f) After it has been determined that each appliance

remaining connected to the common venting sys-

tem properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace

dampers and other gas burning appliances to their

previous conditions of use.

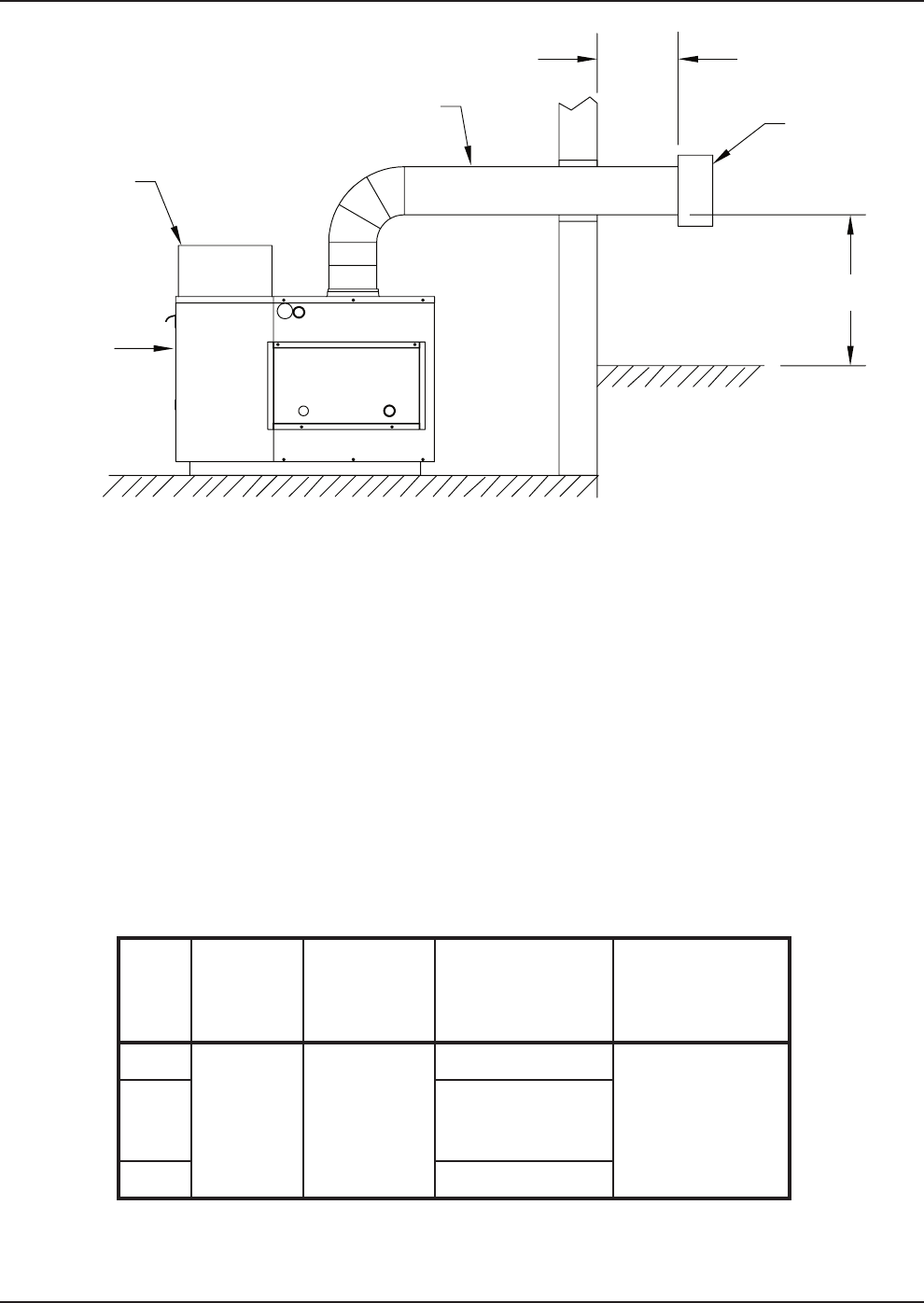

12"

MIN

FLUE EXHAUST

VENT CAP

INSULATED

EXHAUST

VENTING

12" MIN

COMBUSTION

AIR FILTER

BOILER

UNIT

Fig. 19: Horizontal Thru-Wall Venting (Category III)

g) Any improper operation of the common venting

system should be corrected so that the installation

conforms with the latest edition of the NFGC (US)

and the B149 Installation Code (Canada). When

re-sizing any portion of the common venting sys-

tem, the common venting system should be

re-sized to approach the minimum size as deter-

mined using the appropriate tables in Appendix G

in the NFGC (US) and Appendix B of the B149

Installation Code (Canada).

Model

No.

Appliance

Category

Certified

Venting

Material

Vent Size

(inches)

Max. Venting

Length (feet)

122

III

Stainless

Steel

(Gas Tight)

4

70

Subtract 10 ft per

elbow, maximum

three elbows

162

202

242

5

322 6

Table K: Horizontal Thru-Wall Venting (Category III)