12

MAINTENANCE

CUSTOMER RESPONSIBILITIES

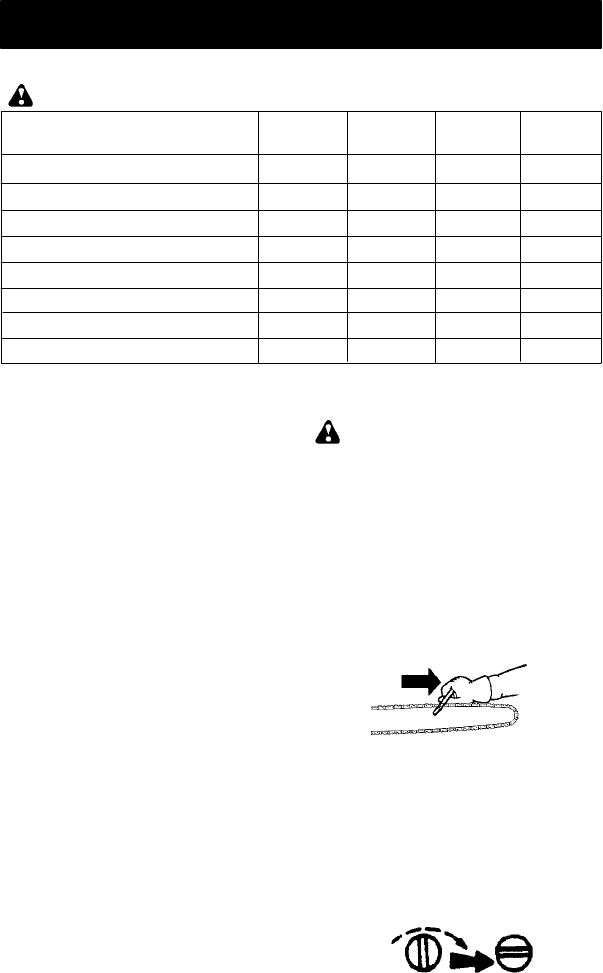

Fillindatesasyoucomplete

regular service

Check for damaged/worn parts

Check for loose fasteners/parts

Check chain tension

Check chain sh arpness

Check guide bar

Inspect and clean unit & labels

Before

Use

After

Use

Every

15 min.

Service

Dates

n

n

n

n

n

nCheck bar and chain oil level

Clean guide bar groove

n

n

n

WARNING: Disconnect power source before performing maintenance.

GENERAL RECO MMENDATIONS

Thewarrantyon this unitdoes notcover

items thatha ve been subjected tooper-

atorabuse or negligence.To receivefull

value from the warranty, the operator

must maintain unit as instructed in this

manual. Various adjustments will need

to be made periodically to properly

maintain your unit. Improper mainte-

nance may cause damage to the unit

andposs ibleinjurytotheoperatororby-

standers.

CHECK FOR D AMA GED OR

WORN PARTS

Contact an authorized s ervi ce dealer for

replacement of wor n or damaged parts.

NOTE: Itis normalforasmall amountof

oil to appear under the saw after motor

stops.Donotconfusethiswith aleaking

oil tank.

S Tri gger Switch -- Ensure t he trigger

switch functi ons properly by squeezing

and hol di ng the tri gger switch. Make

sure mo tor starts and stops.

S OilTank -- Disconti nueuse ofchai nsaw

if oi l tank shows signs of damage or

lea ks.

S Extension C or d -- Discontinue use if

chai n saw exte nsion cord shows signs

of damage or wear.

CHECK FOR L OOSE FASTENERS

AND PARTS

S Bar Clamp Nut s

S Chain

S Bar Adjusti ng Screw

CHECK CHAIN TENSION

WARNING: Wear protective

gloves when handling chain. The chain

issharpandcancutyouevenwhenitis

not moving.

Chain t ension is ver y i m port ant . Chai n

stretches during use. Thi s is esp ecially

tr ueduringthe fir stfew t imesyou useyour

saw. Al ways check chain tension each

time yo u use your saw.

1. Unplug u nit from the power source.

2. Use a screwdriver to move chain

around guide bar to ensure kinks do

not exist. The chain should rotate

freely.

NOTE: It is recommended that the saw

be turned upside down for c hain

tensioning.

3. Loosen barc lamp nuts until theyare

finger tight against the bar clamp.

4. Turn the adjustin g screw clo ckw ise

until the chain soli dly contacts bott om

of guide bar rail . Then, t urn a djusting

screw an add itiona l 1/4 tur n. Thi s is

correct chain tensi on setting.

Adjusting Screw -- 1/4 Turn

NOTE: To ti ghten the c hain, t ur n the ad-

justin g screw clockwise; to loosen the

chain, turn the adj usti ng screw counter-

clockwi se .