MegaTherm Commercial Pool Heating Boiler

Page 7

flamme d’une chandelle ou la fumée d’une

cigarette, d’une cigare ou d’une pipe.

6. Une fois qu’il a été déterminé, selon la méthode

indiquée ci-dessus, que chaque appareil raccordé

au systéme d’évacuation est mis à l’air libre de

façon adéquate. Remettre les portes et les

fenêtres, les ventilateurs, les registres de

cheminées et les appareils au gaz à leur position

originale.

7. Tout mauvais fonctionnement du systéme

d’évacuation commun devrait être corrigé de

façon que l’installation soit conforme au

National Fuel Gas Code, ANSI.Z223.1 et (ou)

aux codes d’installation CSA-B149.1. Si la

grosseur d’une section du système d’évacuation

doit être modifiée, le système devrait être

modifié pour respecter les valeurs minimales des

tableaux pertinents de l’appendice G du National

Fuel Gas Code, ANSI Z2231.1 et (ou) des codes

d’installation CSA-B149.1.

2.3 Installation of Outdoor Boilers

1. Locate the boiler to provide the clearances as

listed in Table 1, “Minimum Boiler Clearances.”

2. Do not place the boiler in an enclosure or wall

recess. Avoid locations where wind deflection

off structures might cause downdraft. When such

wind conditions are possible, place the heater at

least 3 feet (0.9m) from the structures.

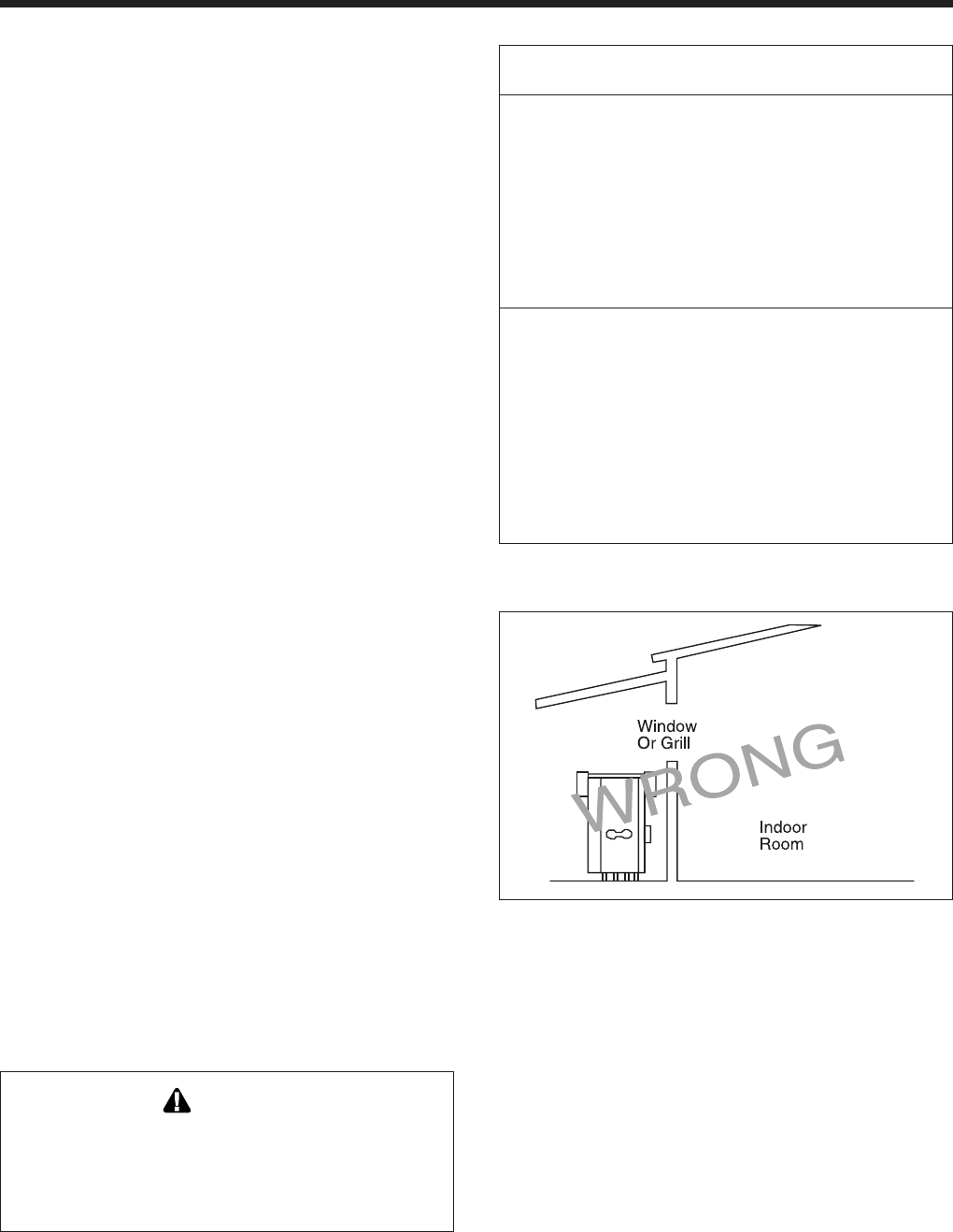

3. Never install the boiler under any kind of roof

overhang. Do not place the boiler below or

adjacent to any doors, windows, louvers, grills,

etc., which connect in any way with an inhabited

area of a building. This includes other structures

such as garages or utility rooms (see Figure 7).

4. Although these models are CSA designed

certified for outdoor installations, such

installations are not recommended in areas where

the danger of freezing exists unless proper

precautions are taken for freeze protection.

Outdoor installations are not recommended in

areas where the danger of snow blockage exists.

WARNING

Liquefied petroleum gas is heavier than air.

Therefore, the pool heating boiler should not be

installed in pits or other locations where gas

could accumulate.

The boiler should be located a safe distance from

Propane gas storage and filling equipment. Consult

local codes and fire protection authorities for advice

on specific installation restrictions.

2.4 Gas Supply and Piping

Review the following instructions before

proceeding with the installation.

1. Verify that the boiler is fitted for the proper type

of gas by checking the rating plate. MegaTherm

boilers are normally equipped to operate below a

2000 foot (609.6m) altitude. Boilers equipped to

operate at higher altitudes have appropriate

stickers or tags attached, also printed information

on rating plate.

2. Use the figures in Table 3 to provide adequate

gas piping from the gas meter to the boiler.

3. A sediment trap (drip leg) must be provided

ahead of the gas controls (see Figure 8). A

manual gas shutoff valve must also be provided

for service convenience and safety. Check the

local codes.

Boiler Each Opening*

Size square inches

square cm

500 125

806.5

600 150

967.8

715 179

1154.9

850 213

1374.3

1010 253

1632.4

1200 300

1935.6

1430 358

2309.8

1670 418

2696.9

1825 457

2948.6

* Net Free Area.

Check with louver manufacturers for net free area of louvers.

Correct for screen resistance to the net free area if a screen is

installed. Check all local codes applicable to combustion air.

Area indicated is for one of two openings: one at floor level

and one at the ceiling, so the total net free area could be

double the figures indicated. For special conditions refer to the

latest editon of ANSI Z223.1.

Consult factory if openings do not communicate directly

through the walls with the outdoors.

Table 2. Minimum Recommended Air Supply to Boiler.

Figure 7. Incorrect Outdoor Installation.