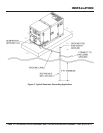

PAGE 16 — DCA250SSI 3-POSITION WHEEL GEN. • OPERATION AND PARTS MANUAL — REV. #0 (01/13/11)

GENERATOR

This generator is a 220 kW generator (Figure 3) equipped

with a 3-position voltage selector wheel, and is designed as

a high quality portable (requires a trailer for transport) power

source for telecom sites, lighting facilities, power tools,

submersible pumps and other industrial and construction

machinery.

ENGINE OPERATING PANEL

The “Engine Operating Panel” is provided with the following:

Tachometer

Emergency Stop Switch

Water Temperature Gauge

Oil Pressure Gauge

Charging Ammeter Gauge

Fuel Level Gauge

Battery Switch

Pre-Heat Lamp

5 Engine Alarm Lamps

Engine Speed Switch

GENERATOR CONTROL PANEL

The “Generator Control Panel” is provided with the following:

Frequency Meter (Hz)

AC Ammeter (Amps)/AC Voltmeter (Volts)

Engine Control Unit (ECU)

Ammeter Change-Over Switch

Voltmeter Change-Over Switch

3-Position Selector Switch

Voltage Regulator

Pilot Lamp

Panel Light/Panel Light Switch

3-Pole, 800 amp Main Circuit Breaker

“Control Box” (located behind the Gen. Control Panel)

• Automatic Voltage Regulator

• Current Transformer

• Over-Current Relay

• Voltage Rectifi er

• Starter Relay

• Diagnostic Panel

OUTPUT TERMINAL PANEL

The “Output Terminal Panel” is provided with the following:

Three 120/240V output receptacles (CS-6369), 50A

Three auxiliary circuit breakers, 50A

Two 120V output receptacles (GFCI), 20A

Two GFCI circuit breakers, 20A

Eight output busbar terminal lugs (3Ø power)

Battery Charger/Water Heater (Optional)

OPEN DELTA EXCITATION SYSTEM

These generators are equipped with a state of the art

“Open-Delta” excitation system. The open delta system

consist of an electrically independent winding wound

among stationary windings of the AC output section.

There are four connections of the open delta A, B, C and

D. During steady state loads, the power from the voltage

regulator is supplied from the parallel connections of A to

B, A to D, and C to D. These three phases of the voltage

input to the voltage regulator are then rectifi ed and are the

excitation current for the exciter section.

When a heavy load, such as a motor starting or a short

circuit occurs, the automatic voltage regulator (AVR)

switches the confi guration of the open delta to the series

connection of B to C. This has the effect of adding the

voltages of each phase to provide higher excitation to the

exciter section and thus better voltage response during the

application of heavy loads.

The connections of the AVR to the AC output windings are

for sensing only. No power is required from these windings.

The open-delta design provides virtually unlimited excitation

current, offering maximum motor starting capabilities. The

excitation does not have a “fi xed ceiling” and responds

according the demands of the required load.

ENGINE

This generator is powered by a 6 cylinder, water cooled,

direct injection, turbocharged air-cooled ISUZU BH6UZ1X

diesel engine. The engine is designed to meet every

performance requirement for the generator. Reference

Table 1 for engine specifi cations.

In keeping with MQ Power’s policy of constantly improving

its products, the specifi cations quoted herein are subject

to change without prior notice.

ELECTRIC GOVERNOR SYSTEM

The electric governor system controls the RPMs of the engine.

When the engine demand increases or decreases, the

governor system regulates the frequency variation to ±.25%.

EXTENSION CABLES

When electric power is to be provided to various tools or

loads at some distance from the generator, extension cords

are normally used. Cables should be sized to allow for

distance in length and amperage so that the voltage drop

between the generator and point of use (load) is held to

a minimum. Use the cable selection chart (Table 6) as a

guide for selecting proper extension cable size.

GENERAL INFORMATION