16

Section 4: Maintenance & Lubrication

PR1660, PR1672 & PR1690 Powered Rakes 314-216M

10/20/06

Land Pride

Table of Contents

Slip Clutch Maintenance

Slip clutches should be “run-in” prior to initial operation

and after long periods of inactivity. To prevent driveline

and gearbox damage, repeat “Run-In” instructions at the

beginning of each season and when moisture and/or

condensation seizes the inner friction disks.

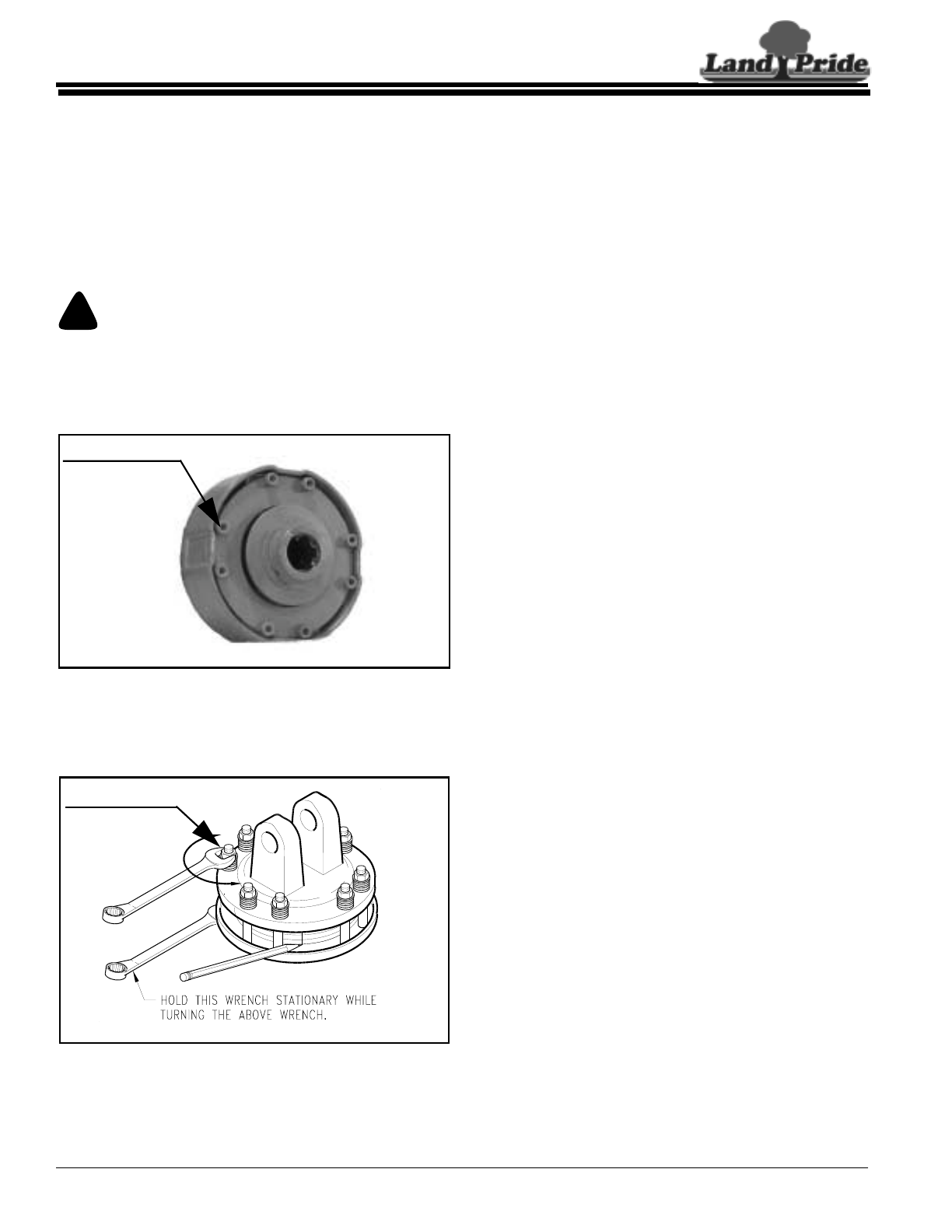

Your Powered Rake will have one of two types of slip

clutches. One is adjustable with hex socket bolts and the

other is adjustable with hex head bolts. Refer to

Figure 4-1 and Figure 4-2 to determine which slip clutch

your Powered Rake has. Follow run-in and assembly

instructions for your particular slip below.

Slip Clutch with Hex Socket Bolts

If your clutch has enclosed friction disks and is tensioned

with hex socket bolts as shown in Figure 4-1, follow

clutch run-in and assembly instructions below.

If your clutch has exposed friction disks and is tensioned

with hex head bolts as shown in Figure 4-2, skip to “Slip

Clutch with Hex Head Bolts” on page 17.

Clutch Run-in (with hex socket bolts)

Refer to Figure 4-1:

1. Loosen counterclockwise all 8 hex socket bolts

uniformly 6 full turns.

2. Cycle clutch on and off 5 or 6 times (15 seconds on

and 15 seconds off) with the engine operating at half

throttle.

3. Tighten clockwise all 8 hex socket bolts fully back.

Clutch is ready for use.

Clutch Assembly (with hex socket bolts)

Refer to Figure 4-3 on page 17:

If clutch run-in indicated that one or more of the friction

disks did notslip,then the clutch must be disassembled into

separate parts.

1. Rotate the 8 hex head socket bolts (#4) all the way out

to free stop flange (#5).

2. Rotate stop flange (#5) and remove from housing (#1)

3. Remove the following inner components:

a. Spring kit (#6)

b. Pressure flange (#7)

c. 1st Friction disk (#8)

d. Hub with flange and pull collar (#2 & #3)

e. 2nd Friction disk (#8)

f. Bearing (#9)

4. Inspect all components and replace to their original

position. Make certain stop flange (#5) is replaced

with its flange down as shown.

5. Fully tighten all 8 hex socket bolts (#4).

Maintenance

Proper servicing and adjustment is the key to the long life

of any implement. With careful and systematic inspection,

you can avoid costly maintenance, time and repair.

After using your Powered Rake forseveral hours, check all

bolts to be sure they are tight.

Replace any worn, damaged or illegible safety labels by

obtaining new labels from your Land Pride Dealer.

!

CAUTION

BEFORE any maintenance is performed, lower the Powered

Rake tothe ground, stoptractor engineand remove ignitionkey.

DO NOT attempt to make maintenance adjustments while

tractor is running.

Slip Clutch with Hex Socket Bolts

Figure 4-1

Slip Clutch with Hex Head Bolts

Figure 4-2

Hex Socket Bolts

21270

24501

Hex Head Bolts

Section 4: Maintenance & Lubrication