TP-6843 1/13 Section 4 Scheduled Maintenance 47

4.2 Lubrication System

See the service schedules in Section 4.1 for oil change

and oil filter replacement intervals. See the service

views in Section 1.7 for the oil drain, oil dipstick, oil fill,

and oil filter locations.

4.2.1 Low Oil Pressure Shutdown

The low oil pressure (LOP) shutdown feature protects

the engine against internal damage if the oil pressure

drops below a minimum pressure because of oil pump

failure or other malfunction.

Note: The LOP shutdown feature does not protect

against damage caused by operating when the

oil level is low; it is not a low oil level shutdown.

Check the oil level regularly, and add oil as

needed.

4.2.2 Oil Check

The generator set is shipped with oil. Before operating

the generator set, check the engine oil in the

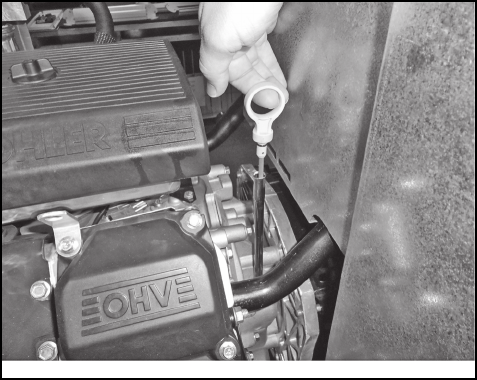

crankcase. See Figure 4-1.

Maintain the oil level at or near, not over, the full mark

on the dipstick. Add 5W-30 synthetic oil when the oil

level is low.

Check the oil level before each use. For extended

operation, check the oil level every 8 hours. Do not

check the oil level when the generator set is running.

Shut down the generator set and wait several minutes

before checking the oil.

Figure 4-1

Figure 4-1 Oil Check (typical)

4.2.3 Engine Oil Recommendation

Use 5W-30 API (American Petroleum Institute)

Service Class SG, SH, or SJ synthetic oil. Synthetic oil

oxidizes and thickens less than other oils and leaves

the engine intake valves and pistons cleaner.

4.2.4 Oil Change Procedure

Note: Dispose of all waste materials (engine oil, fuel,

filter, etc.) in an environmentally safe manner.

Drain the oil while it is still warm.

1. Drain the oil.

a. Press the OFF button on the generator set

controller.

b. Disconnect the AC power to the generator set.

c. Disconnect the generator set engine starting

battery, negative (–) lead first.

d. Open the housing service door and remove

roof panel.

e. Clean the area around the dipstick and oil fill

cap.

f. Remove the screw in plug on drain fitting in

skid rail.

g. Open the oil drain valve on the engine.

h. Remove the dipstick and oil fill cap. Allow time

for the engine oil to drain completely.

i. Close the oil drain valve. Replace the cap in

skid rail.

j. Replace the dipstick.

2. Replace the oil filter.

a. Clean the area around the oil filter. Remove

the oil filter by rotating it counterclockwise with

an oil filter wrench.

b. Clean the gasket sealing surface of the oil filter

adapter.

c. Apply a light coat of clean oil to the rubber seal

of the new oil filter.

d. Install the new oil filter following the

instructions provided with the filter.

KPS_026