TP-5700 7/9336 Section 7 Electrical Requirements

7.2 Electrical Connections

Several electrical connections must be made between

the generator set and other components of the system

for proper operation. Because of the large number of

accessories and possible combinations, this manual

does not address specific applications. Refer to the

submittal catalog accessory drawings and wiring

diagrams for connection and location. Most

field-installed accessory kits include installation

instructions.

For customer-supplied wiring, select the wire

temperature rating in Figure 7-2 based upon the

following criteria:

D Selectrow1,2,3,or4ifthecircuitratingis

110 amperes or less or requires #1 AWG (42.4 mm

2

)

or smaller conductors.

D Select row 3 or 4 if the circuit rating is greater than

110 amperes or requires #1 AWG (42.4 mm

2

)or

larger conductors.

Comply with applicable national and local codes when

installing a wiring system.

Row Temp. Rating Copper (Cu) Only Cu/Aluminum (Al) Combinations Al Only

1

60_C (140_F)

or

75_C (167_F)

Use No. * AWG, 60_C

wire or use No. * AWG,

75_Cwire

Use 60_C wire, either No. * AWG Cu, or

No. * AWG Al or use 75_C wire, either

No.*AWGCuorNo.*AWGAl

Use 60_Cwire,No.*

AWG or use 75_Cwire,

No. * AWG

2

60_C (140_F) Use No. * AWG, 60_C

wire

Use 60_C wire, either No. * AWG Cu or

No. * AWG Al

Use 60_Cwire,No.*

AWG

3

75_C (167_F) Use No. *[ AWG, 75_C

wire

Use 75_C wire, either No. * [ AWG Cu or

No. *[ AWG Al

Use 75_Cwire,No.*[

AWG

4

90_C (194_F) Use No. *[ AWG, 90_C

wire

Use 90_C wire, either No. * [ AWG Cu or

No. *[ AWG Al

Use 90_Cwire,No.*[

AWG

* Thewire sizefor 60_C (140_F)wire isnot requiredto beincluded inthemarking. If included,thewire sizeis basedonampacities for thewire

given in Table 310-16 ofthe National Electrical Coder, in ANSI/NFPA70, and on 115% of themaximum current that thecircuit carries under

rated conditions. The National Electrical Coder is a registered trademark of the National Fire Protection Association, Inc.

[ Usethelargerofthefollowingconductors: thesamesizeconductorasthatusedforthetemperaturetestoroneselectedusingtheguidelinesin

the preceding footnote.

Figure 7-2 Terminal Markings for Various Temperature Ratings and Conductors

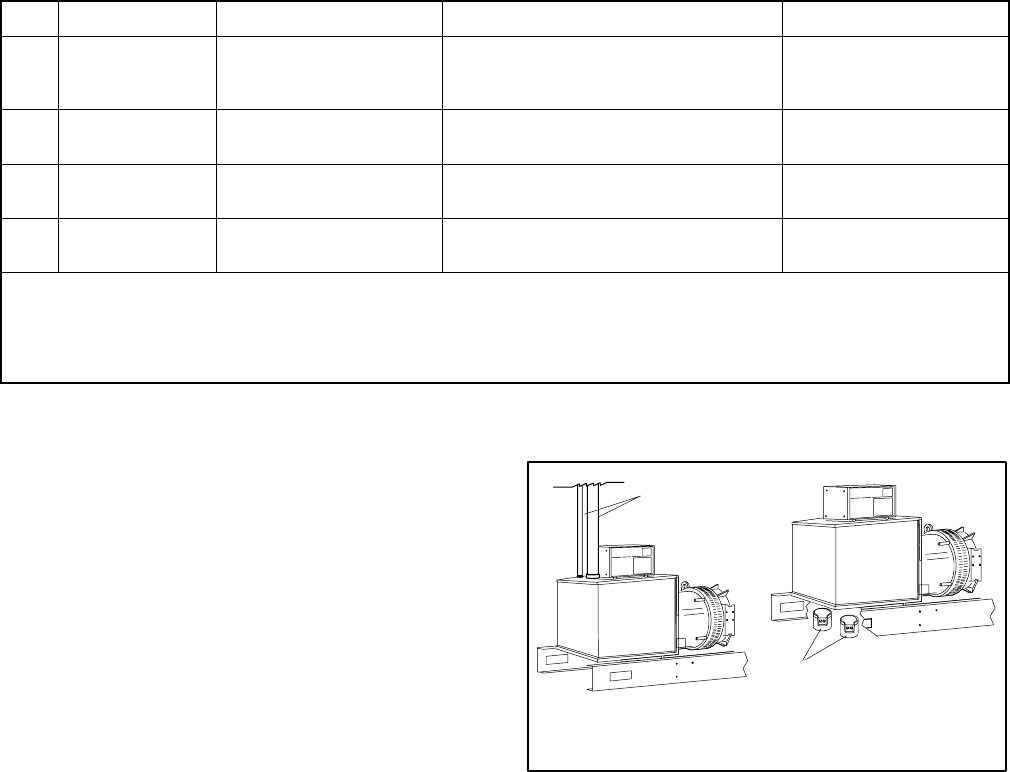

7.3 Load Lead Connections

Load leads being broughtinto the generator can enter in

a number of different areas. On generators 300 kW and

below the most commonly used is the bottom entry,

where conduit is “stubbed up” into the junction box from

below. Other methods include flexible conduit roughed

into the sides or top of the junction box. When using this

method, be sure not to block the front or rear of the

controller,as doingso willprevent accessto itfor service

purposes. See Figure 7-3.

On generators larger than 300 kW, a junction box is

mounted on the rear of the generator. Larger sets may

have oversize junction boxes suppliedas an option or to

accommodate buss bar connections. Consult the

dimensional drawing on your unit for detailed

information.

TP-5700-7

1

2

1. Conduit from ceiling

2. Conduit stubbed up from below

Figure 7-3 Typical Load Lead Connection