TP-5700 7/9316 Section 4 Air Requirements

4.6 Liquid-Cooled Models

The three most common liquid cooling systems used for

generator setsare unit-mounted radiator, city water, and

remote radiator cooling. Since each involves somewhat

different installation considerations, they will be

discussed separately.

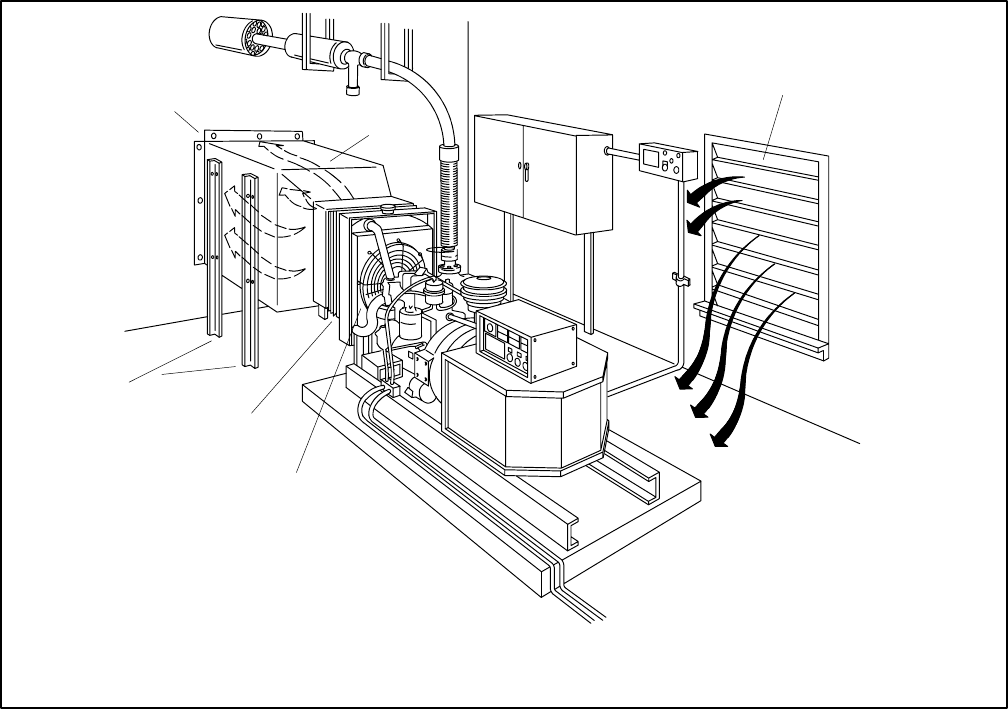

4.7 Unit-Mounted Radiator Cooling

This is the most c ommon c ooling system used for

engine-driven generator sets 20 kW and larger. T he major

system components are an engine-driven fan and

circulating water pump, a radiator , and a thermostat. The

pump circulates water through the engine until it reaches

operating temperature. Then the engine thermostat opens

and allows circulation through the radiator . It can also close,

restricting the flow as necessary to prevent overcooling.

The fan blows air from the engine side of the radiator across

the c ooling surface as s hown i n F igure 4-8.

Cooling air flow can be reversed by using a suction fan,

but this is generally not recommended because it may

interfere with generator cooling air flow, which moves in

the same direction as the engine’s standard pusher fan.

Also, a suction fan would result in higher temperature

combustion air being drawn into the air cleaner,

reducing the maximum engine power available.

Whenever a generator set is installed inside a building or

enclosure, the radiator air should be ducted outside the

room or enclosure. A typical arrangement is shown in

Figure 4-8. Ductwork should be as short, straight, and

unobstructed as possible. Static pressure restrictions of

more than 1/2 i nch (1.3 cm) water column o n t he radiator

outlet o r i nlet air will reduce a ir flow to the point of limiting

maximum power and/or ambient temperature that causes

overheating.

7

8

9

10

11

12

7. Self-supporting duct work

8. Air out

9. Air inlet opening

10. Pusher fan

11. Flexible section

12. Support legs

Figure 4-8 Radiator-Cooled Generator Set Installation