7

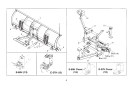

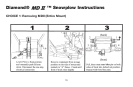

1. Blade

High strength steel. Built to last.

2. Adjustable Tripedge Extension Springs

Tripedge gives way when objects are struck at ground level.

NOTE: Trip spring tension should be checked on a regular basis

during the snowplowing season. See Page 18 under

SNOWPLOW Paragraph 4 for more information.

3. Power Angling Cylinders

Enables the operator to hydraulically position the moldboard

straight, or to right or left, by simply activating the fingertip

control switch.

4. MDII Attaching System

Rubber coated stainless steel pins give you the choice of

removing the plow, mount, hydraulics, and lights (blue pins) or to

remove only the plow (yellow pins).

5. Cutting Edge (optional)

Replaceable, high carbon steel provides extra long operating life.

Recommended for commercial plowers.

8. Wear Shoes

Wear shoes are an integral part of the tripedge to reduce wear.

7. Electric Hydraulic Power Unit

Operates snowplow hydraulically - raises, lowers, angles, holds

and floats blade in plowing position.

8. Pushframe

Designed to attach snowplow to vehicle, to pivot blade for angle

plowing, and to hold plow at proper distance in front of vehicle.

9. Upper/Lower Pivot Pins

Pins that attach blade to pushframe.

10. Lift Arm

Dual chain locks in position to lift snowplow. WARNING: Lift arm

extends beyond bumper of vehicle. To minimize damage

from a front-end collision, lift arm should be removed from

vehicle when snowplow is removed.

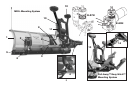

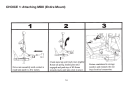

11. MDII

®

Mounting System

Allows for fast, complete removal of all front end hardware,

snowplow lights, hydraulic unit, moldboard, sector and

pushframe, in one complete module.

12. Snowplow Lights

Lights and brackets comply with the Federal Motor Vehicle

Safety Standards.

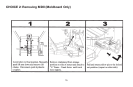

13. Tubular PULL-AWAY™ Mounting System

Allows for fast removal of all snowplow components in two

complete, easy to manage, modules.

14. Tubular PULL-AWAY™ Easy Hitch™ System

Allows moldboard, sector and pushframe to be detached and

attached as a separate module in minutes.

Get to know your Diamond Tripedge Snowplow