22

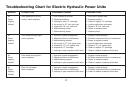

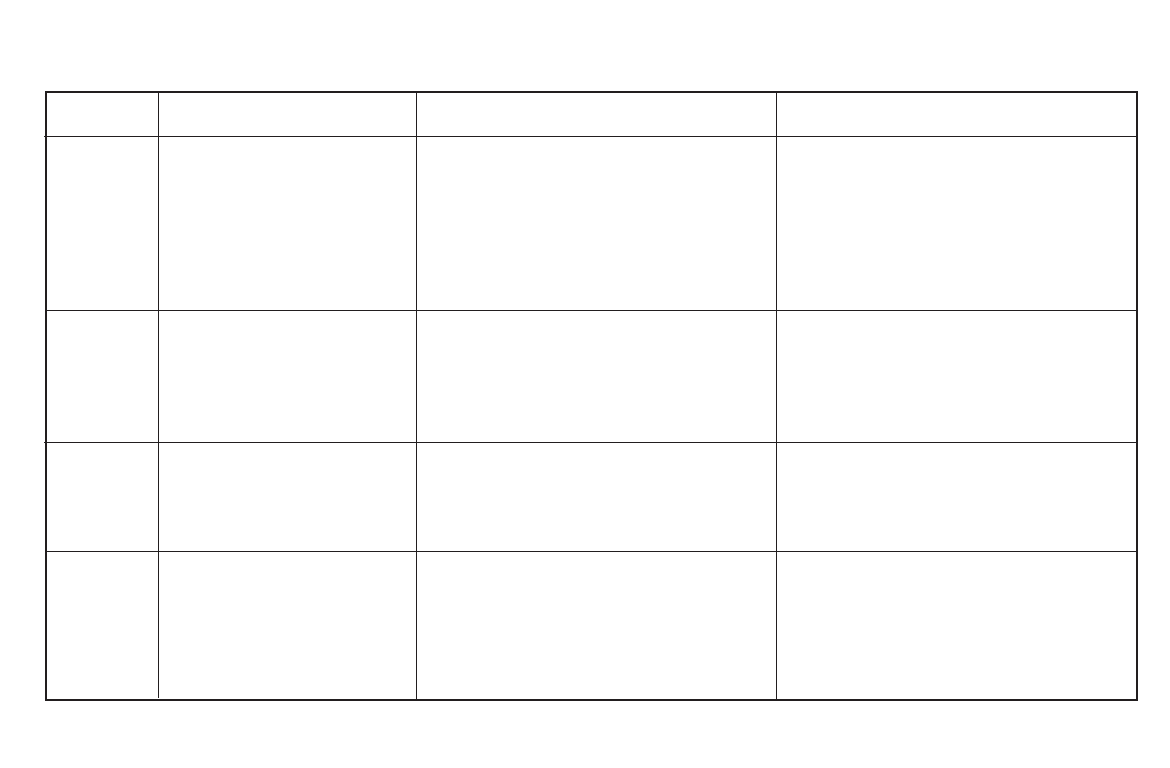

MODEL CONDITION POSSIBLE CAUSE CORRECTION

All Plow will not hold in 1. Air in cylinders and hoses. 1. Bleed cylinders and hoses. Tighten P.A.

Power angled position. cylinder gland nut.

Angling 2. Leaking “C” cartridge O-rings. 2. Replace O-rings.

Models 3. Leaking or open pilot check valve. 3. Clean or replace pilot check valve.

4. Leaking crossover relief valve. 4. Clean or replace crossover relief valve.

5. Crossover relief valve opening at 5. Replace crossover relief valve.

too low a pressure.

All Motor does not operate. 1. Discharged or defective battery. 1. Recharge or replace battery.

Power 2. Loose or corroded electrical connections. 2. Clean and tighten electrical connections.

Angling 3. Inoperative starter solenoid. 3. Replace starter solenoid.

Models 4. Malfunctioning control switch. 4. Replace control switch.

5. Malfunctioning motor. 5. Repair or replace motor.

All Plow does not lower. 1. No current to “A” coil. (black wire) 1. Locate malfunction and repair.

Power 2. “A” cartridge jammed in closed position. 2. Clean or replace “A” cartridge.

Angling 3. Inoperative “A” coil. (black wire) 3. Replace “A” coil. (black wire)

Models

All Plow creeps down. 1. Leaking “A” cartridge. 1 Clean or replace “A” cartridge.

Power 2. Leaking “A” cartridge O-ring. 2. Replace O-ring.

Angling 3. Leaking “B” check valve. 3. Clean or replace “B” check valve.

Models 4. Leaking ram packing cup. 4. Replace ram packing cup.

5. Leaking O-ring at bottom of lift cylinder. 5. Replace O-ring.