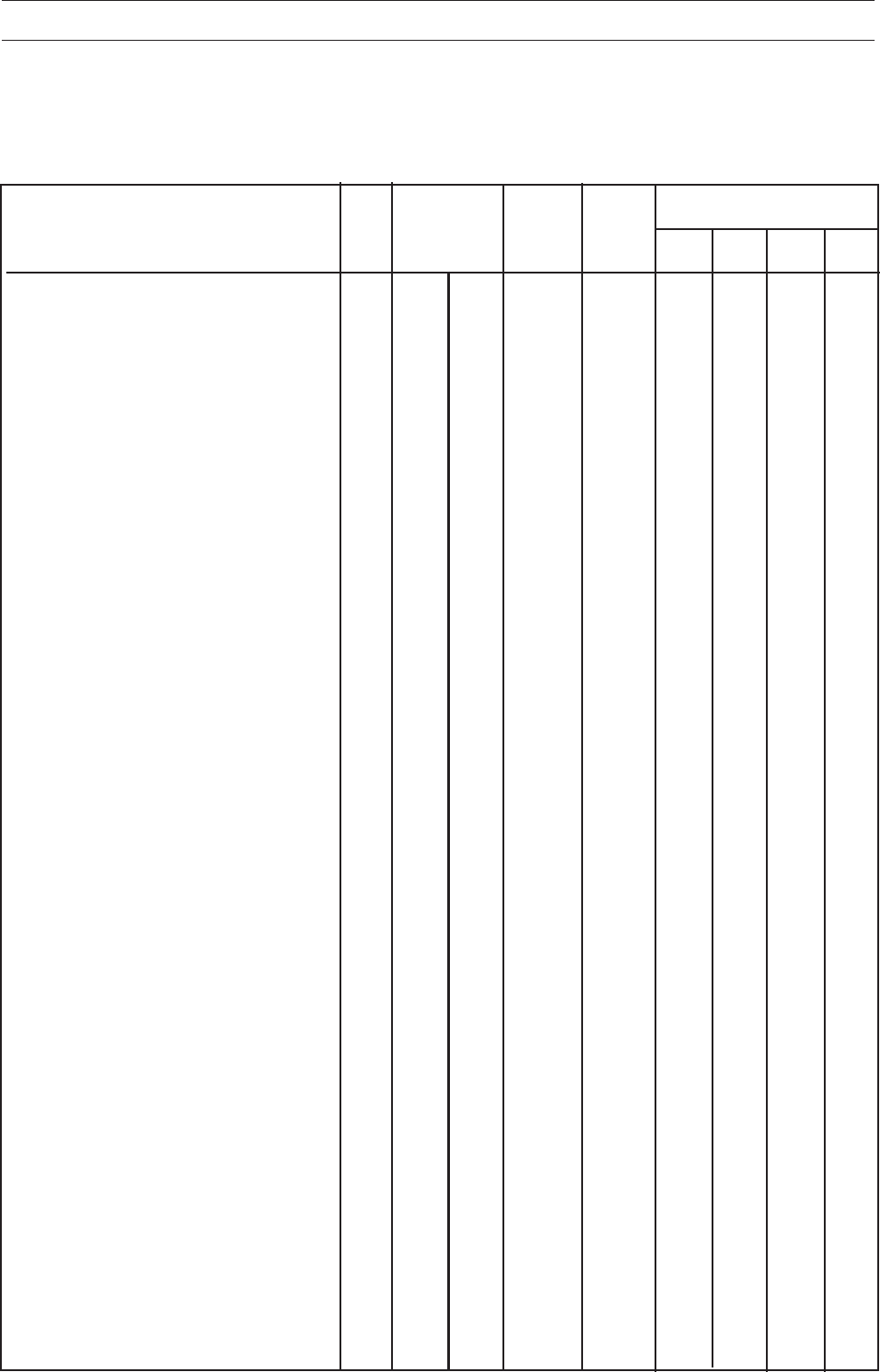

18 – English

MAINTENANCE

Maintenance interval in

hours

Daily main-

tenance

before after

Weekly

3)

main-

tenance

At least

once a

year

Maintenance schedule

The following is a list of the maintenance which should be conducted on the machine. For the items which

are not described in these instructions go to an authorised service workshop.

Check for fuel and oil leakage - ❍

Check the parking brake 25 ●

Check the engine oil level (when you

refuel) 43 ●

Check the fuel pump air filter 27 ●●

Check the seat safety switch 28 ●

Check the lift lever safety switch 28 ●

Check the parking brake safety switch 28 ●

Check/clean the engine cooling air intake 21 ●●

Check the cutting unit: 29 ●

• blades are secure 33 ●

• condition of blades (sharpness,

shape, etc.) 33 ●

• blade synchronisation (90° between

BioClip) 33 ●

Check steering wires (for play, etc.) 22 ●

Check fasteners (screws, nuts, etc.) - ❍

Start engine and blades, listen for noise - ❍

Clean underside of cutting unit 33 ●

Clean transmission air intake 21 ●●

Check battery acid level 28 ●

Check transmission oil level 45 ●

Check the condition of belts, pulleys, etc. - ❍

Check for damage - ❍

Check tyre pressures (60 kPa) 25 ●

Check for damage to wire guide at

articulated joint - ❍

Clean thoroughly around engine - ❍

Clean thoroughly around transmission - ❍

Clean all belts, pulleys, etc. 41 ●

Lubricate the wire for the differential lock 42 ●

Lubricate belt tensioner (nipple) 45 ●

Lubricate triangle link (nipple) 44 ●

Lubricate the driver’s seat 44 ●

Lubricate all wires 41 ●

Lubricate safety lock on cutting unit 44 ●

Lubricate inner stud on cutting unit 44 ●

Lubricate slot for cutting unit tool frame 44 ●

Lubricate bearing surfaces on cutting unit 44 ●

Clean inside frame tunnel - ❍

Lubricate pedal mechanism inside frame

tunnel 41 ●

Lubricate the gear lever 43 ●

Lubricate the parking brake wire 45 ●

25 50 100 300

PageMaintenance