Page 14 For technical questions, please call 1-800-444-3353. SKU 67596

Start Procedure

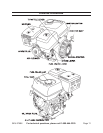

Before starting the engine:

Follow the Set Up a.

Instructions to prepare the

equipment.

Inspect the equipment and b.

engine. Make sure the pump

has the Pump Breather Plug

installed.

Replace the non-vented c.

brass oil plug with the

aluminum Pump Breather

Plug.

Fill the engine with the d.

proper amount and type of

both fuel and oil.

Read the Equipment e.

Operation section that

follows.

Point Nozzle in safe direction and 1.

squeeze trigger to release all pres-

sure from the pump.

Turn the fuel valve lever to its 2.

“OPEN” position.

Turn the ignition switch to its ON or 3.

RUN position.

Then, turn the engine choke lever 4.

to its “CHOKE” position for cold

start. Set the choke lever in the “1/2

CHOKE” position when starting a

warm engine.

Close the throttle.5.

Grasp the starter handle, and pull 6.

slowly until resistance is felt. While

holding the handle, allow the starter

rope to rewind slowly. Then, pull the

starter handle with a rapid, full arm

stroke. Once again while holding

the handle, allow the rope to rewind

slowly. Repeat as necessary, until

the engine starts.

After the engine starts and warms 7.

up, slowly move the choke lever to its

“RUN” position.

IMPORTANT: Allow the engine to 8.

run at no load (low pressure) for ve

minutes after each start-up so that

the engine can stabilize.

Move the throttle up to operating 9.

speed. Operating speed is maximum

speed (fast or rabbit), except during

operational break-in period.

Break-in Period

Breaking-in the engine will help to 1.

ensure proper equipment and engine

operation.

The operational break-in period will 2.

last about 3 hours of use. During this

period:

Do not apply a heavy load to the •

equipment.

Do not operate the engine at its •

maximum speed.

The maintenance break-in period will 3.

last about 20 hours of use. After this

period:

Change the engine oil.•

Under normal operating conditions

subsequent maintenance follows the

schedule in the MAINTENANCE AND

SERVICING section.