5. Insert a starting pin into the table surface, using the pin location that best supports your work.

6. Inspect your stock or pattern for any irregularities that might transfer to the cut.

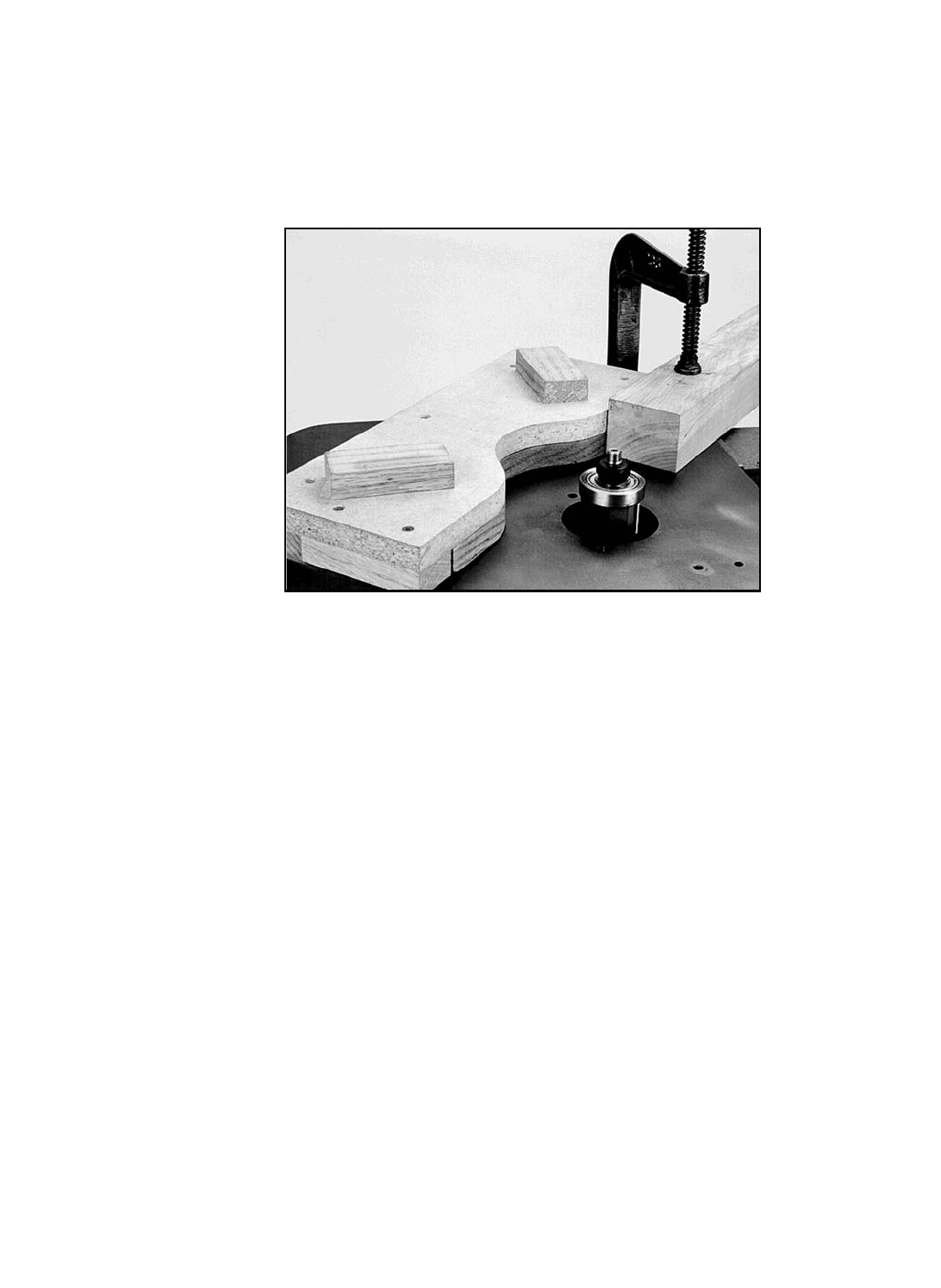

7. Use some type of hold-down fixture and guard when doing freehand work. See Figure 24.

Figure 24

8. Make a sample cut on a piece of scrap wood.

9. If everything is correct, feed your workpiece along the cutter, using firm pressure to keep your

work against the rub collar. Feed against the cutter rotation only.

- 25 -

Notice in Figure 24, the operator is not exposed to the cutting edge of the cutter. Cutters are remov-

ing material from the bottom of the workpiece.

Sometimes the starting pin will not be in the most advantageous position. Using a board firmly

clamped to the shaper table, as shown in Figure 24, will give you the same support as the starting

pin, with a better starting position. Always use a starting support when doing freehand work.

When using a solid rub collar, do not use excessive pressure when running your workpiece through

the shaper. Otherwise, a groove may burn into your pattern and be transferred to your workpiece.

Instead, take several passes, using lighter pressure against the rub collar. If you find this to be a con-

sistent problem, you may consider using ball bearing rub collars instead of solid collars.