- 16 -

Outfeed Fence

Cutter Rotation

Workpiece

Infeed Fence

Feed Direction

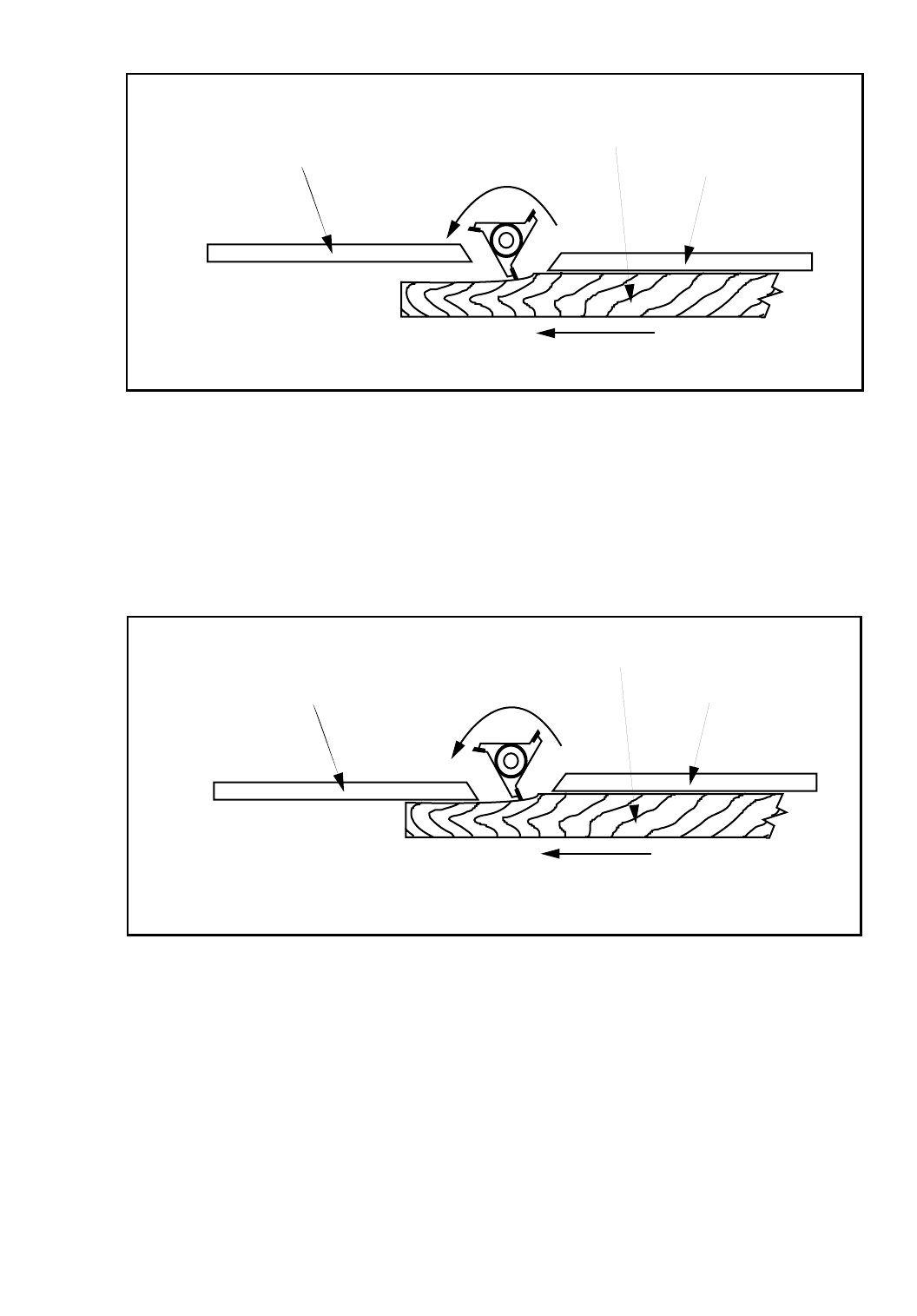

Improper Fence Adjustment

Figure 11

When the shaping operation removes the entire face of the workpiece, the shaped surface will not

be supported by the outfeed fence when the fences are paralleled, or mis-aligned, as shown in

Figure 11. In this case, a test sample of the desired cut should be advanced to the point shown, then

stopped. Once the shaper is turned off and the cutter has come to a complete stop, the outfeed fence

can be re-adjusted to provide support for the milled surface of the workpiece. See Figure 12.

Outfeed Fence

Cutter Rotation Infeed Fence

Workpiece

Feed Direction

Proper Fence Adjustment

Figure 12

When performing work which requires that both fences be in-line – such as a cut where only a por-

tion of the workpiece’s surface comes in contact with the cutter – you should begin by adjusting the

infeed fence to the point where only the desired amount of the workpiece comes in contact with the

knives. Use a test piece to determine your ideal setting. Once your positioning is correct, lock the

infeed fence in place.

Once you adjust the infeed fence to your liking, adjust the outfeed fence to the same plane as the

infeed. Use a high-quality straight edge to ensure parallelism. Lock the outfeed fence in place. Once

again, run a test piece through the shaper to check your results. See Figure 13. Remember to unplug

your shaper while making fence adjustments.