8

Vektor-CD Centrifugal Laboratory Exhaust

®

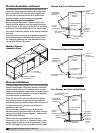

Plenum and Fan Drainage Piping and

Trap Detail (by others)

There are multiple locations for pipe connections, one

on each plenum section, and another on each tubular

fan housing located at the bottom of the scroll. Each

drain should be properly connected to a drainage

system to ensure proper disposal of any water or

condensate that may occur.

• Installed piping to have a downward angle to

allow for drainage

• Fill trap to recommended level before start-up

Y Dim ≥ System Pressure

X Dim ≥ 1/2 System Pressure

Dimension of X and Y are inches.

Bypass Air Plenum (BAP), Isolation

Damper Access & Actuator Mounting

Depending on the configuration and intended

operation of the system supplied, every Vektor plenum

section may not have a weatherhood and bypass air

damper. Typically systems that include a fan which

is on standby will have one less weatherhood and

BAP damper assembly than plenum sections. Refer

to submittal drawings for additional information. The

appropriate guard / cover needs to be removed for

installation, inspection and maintenance.

For Vektor Fans with a Weatherhood

Access to the bypass air plenum damper and the

isolation damper, actuator(s) (optional from factory),

and voltage transformer (optional from factory) is

gained through the removal of the weatherhood

guard / cover. The isolation damper assembly can be

removed from its location by unbolting the frame from

the plenum and removing the flex connector.

Duct Connections to the Bypass Air

Plenum (BAP)

Connecting primary exhaust air ducts is allowed

through the roof curb or through one or more of the

side access panels. To reduce the potential for system

effects in the plenum, the duct connection should

be sized to have a maximum air velocity of 1500 fpm

when entering. When attaching ductwork to the

plenum, care should be taken to ensure a tight fit and

proper seal to prevent leakage of the contaminated

airstream.

Ductwork that is a different size than the removable

access panel can either use a transition to the

plenum’s opening size, or the access panel can be

field modified by cutting an opening to the size of the

ductwork.

Vektor Field Coating Repair Procedure for

Scratched Areas

Standard coating and color for the Vektor laboratory

exhaust system is Greenheck’s Hi-Pro Polyester Gray

(041).

The procedure below details the correct method for

repairing minor scratches in the coating. Each Vektor

unit is supplied with a repair kit for use after the initial

installation.

The kit includes:

• 1 pint Kem Kromik

®

Universal Metal Primer

• 1 pint industrial enamel (Industrial 041 Gray)

• 4 disposable foam brushes

• 1 sheet of sandpaper

• 2 tech data sheets for the two paints

• 1 repair procedure.

1. Scuff affected area to be repaired using medium

sandpaper (provided). Feather the edges.

2. Clean affected area to be touched up using an

alkaline based cleaner and rinse.

3. Apply Kem Kromik

®

primer using the 1 inch foam

brush (provided). Follow technical data sheet

instructions.

4. Allow primer to dry a minimum of 2-1/2 hours

before top coating.

5. Topcoat with Industrial enamel using 1 inch foam

brush (provided). Follow technical data sheets

instructions. Allow painted units to air-dry and

cure before putting into service. See enclosed

Technical Data sheets for detailed drying and

cure schedules at different temperatures.

To order additional coating repair kits please reference

Greenheck’s part number, HAZ2037 HI-PRO GRAY

FIELD DAMAGE REPAIR KIT. Please contact factory

with your fan’s serial number for colors other than our

standard Gray (041).

Y

X

1 inch of water

A

B

C

Detail of bypass air

plenum and blower

housing

Clean out location

1 in. drain coupling in blower

housing and bypass air plenum

Note: Refer to local codes for proper disposal of

potential hazardous drainage.