12

Vektor-CD Centrifugal Laboratory Exhaust

®

Motors

Motor maintenance is generally limited to cleaning

and lubrication. Cleaning should be limited to exterior

surfaces only. Removing dust and grease buildup on

the motor housing assists proper motor cooling. Never

wash-down motor with high pressure spray.

Greasing of motors is only intended when fittings are

provided. Many fractional motors are permanently

lubricated for life and require no further lubrication.

Motors supplied with grease fittings should be

greased in accordance with the manufacturer’s

recommendations. When motor temperature does not

exceed 104ºF (40ºC), the grease should be replaced

after 2000 hours of running time.

Direct drive systems have extended grease lines to

lubricate the motor without removal of any guarding.

Bearings

The bearings for Greenheck fans are carefully

selected to match the maximum load and operating

conditions of the specific class, arrangement, and

fan size. The instructions provided in this manual

and those provided by the bearing manufacturer will

minimize any bearing problems. Bearings are the

most critical moving part of the fan, therefore, special

care is required when mounting them on the unit and

maintaining them.

Greenheck Fan Corporation recommends bearings

to be relubricated quarterly at a minimum. All

Vektor-CD fans use Mobil Mobilith SHC 100 synthetic

grease conforming to NCGI Grade 2. Never mix

greases made with different bases. This will cause a

breakdown of the grease and possible failure of the

bearing. For specific information, contact the factory

representative or the fan system submittals.

Service

V-Belt Drives

The V-belt drive components, when supplied by

Greenheck Fan Corporation, have been carefully

selected for this unit’s specific operating condition.

Caution: Changing V-belt drive components could

result in unsafe operating conditions which may cause

personal injury or failure of the following components:

• Fan Shaft

• Fan Wheel

• Bearings

• V-belt

• Motor

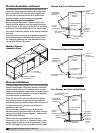

V-Belt Drive Installation — Belt Drive

1. Remove the protective coating from the end of

the fan shaft using mineral spirits or another

similar solvent. Check to ensure that the shaft is

free of nicks and burrs.

2. Slide sheaves on shafts - do not drive sheaves on

as this may result in bearing damage.

3. Align fan and motor sheaves with a straight-edge

or string and tighten.

4. Place belts over sheaves. Do not pry or force

belts, as this could result in damage to the cords

in the belts.

5. Adjust the tension until the belts appear snug.

Run the unit for a few minutes and allow the belts

to “set” properly.

6. With the fan off, adjust the belt tension by moving

the motor pivot plate. When in operation, the

tight side of the belts should be in a straight line

from sheave to sheave with a slight bow on the

slack side.

FAN

MOTOR

FAN

MOTOR

Aligning sheaves with a straight edge