7

Vektor-CD Centrifugal Laboratory Exhaust

®

Fan Installation

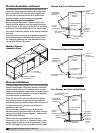

Fan Housing Installation

If the windband is shipped attached to the fan housing

or if the windband is secured to the fan housing

prior to mounting to the plenum, the fan / windband

assembly should be lifted by the lifting lugs located

on the fan housing. Do not lift this assembly by the

lifting lugs located on the windband. Connect fan

to plenum using Excelon™ flex connector found in the

Vektor-CD hardware kit.

Four (4) lifting

lugs located

at top of

windband

Lifting lugs located at top

of bypass air plenum

Lifting lugs located on the

four corners of the base

Windband and nozzle assembly, if required:

1. Place windband on top of nozzle and align brackets with each other.

2. Bolt windband and nozzle together with fasteners provided.

3. Lift the assembly with the lifting lugs at the top of the windband and

place on top of the fan after the fan is placed. Use the fasteners

provided to fasten the nozzle flange to the fan flange.

Span determines the number of lifting lugs to use:

Span

12 inches or less Minimum of four (4) lifting lugs

12 to 18 inches Minimum of six (6) lifting lugs

18 inches or greater Minimum of eight (8) lifting lugs

Lines of attachment

are to be lifted in the

vertical direction to

prevent damage.

Spreader bars

are recommended.

Windband Installation

Using the windband

lifting lugs, place

windband over blower

discharge, aligning

windband support

bracket holes with

bolt holes in blower

housing. Attach

windband to blower

discharge using 316

stainless steel bolts

(provided) through support brackets welded to the

inside of the windband. Use anti-seize gel (provided)

to prevent galling / welding of all stainless steel

fasteners.

Four (4) lifting

lugs located

at top of

windband

Lifting lugs located at top

of bypass air plenum

Lifting lugs located on the

four corners of the base

Windband and nozzle assembly, if required:

1. Place windband on top of nozzle and align brackets with each other.

2. Bolt windband and nozzle together with fasteners provided.

3. Lift the assembly with the lifting lugs at the top of the windband and

place on top of the fan after the fan is placed. Use the fasteners

provided to fasten the nozzle flange to the fan flange.

Span determines the number of lifting lugs to use:

Span

12 inches or less Minimum of four (4) lifting lugs

12 to 18 inches Minimum of six (6) lifting lugs

18 inches or greater Minimum of eight (8) lifting lugs

Lines of attachment

are to be lifted in the

vertical direction to

prevent damage.

Spreader bars

are recommended.

Fan Stack Installation

** Greenheck strongly recommends the use of guy wires on any system

that incorporates the usage of a stack extension and the subsequent

guy wires are to be designed and installed by others.

**Guy wire attachments

Fan Assembly

Stack Extension

If fan requires a stack or stack extension, install on

fan before installing nozzle and windband. Place

gasketing between any sections, blower housing and

initial stack. Use lifting lugs to position each piece

into place. Attach stack or stack extension to blower

housing using 316 stainless steel bolts (provided)

through flanges aligning bolt patterns. Use anti-

seize gel (provided) to prevent galling/welding of all

stainless steel fasteners.

Greenheck strongly recommends the use of guy

wires on any system that incorporates the usage

of a stack extension including inline attenuators.

Subsequent guy wires are to be designed and

installed by others.

1-1/4 inch thru-hole typical

NOTE: Guy wires to be supplied by others. Fastening to

building structure to be provided and engineered by others.

Guy Wire Locations

If your fan requires stack extensions, the use of guy

wires is recommended. See drawing for guy wire

connection locations.

Note: Keep 36 inches minimum spacing around unit

to provide adequate clearance for servicing or

repairing unit.

Bypass Air Plenum Installation

Four (4) lifting

lugs located

at top of

windband

Lifting lugs located at top

of bypass air plenum

Lifting lugs located on the

four corners of the base

Windband and nozzle assembly, if required:

1. Place windband on top of nozzle and align brackets with each other.

2. Bolt windband and nozzle together with fasteners provided.

3. Lift the assembly with the lifting lugs at the top of the windband and

place on top of the fan after the fan is placed. Use the fasteners

provided to fasten the nozzle flange to the fan flange.

Span determines the number of lifting lugs to use:

Span

12 inches or less Minimum of four (4) lifting lugs

12 to 18 inches Minimum of six (6) lifting lugs

18 inches or greater Minimum of eight (8) lifting lugs

Lines of attachment

are to be lifted in the

vertical direction to

prevent damage.

Spreader bars

are recommended.

Span No. of Lifting Lugs

12 inches or less Minimum of 4 lifting lugs

12 to 18 inches Minimum of 6 lifting lugs

18 inches or greater Minimum of 8 lifting lugs

Span determines the number of lifting lugs to be used

during installation: