SERVICE MISCELLANEOUS

SERVICE MISCELLANEOUS - 36

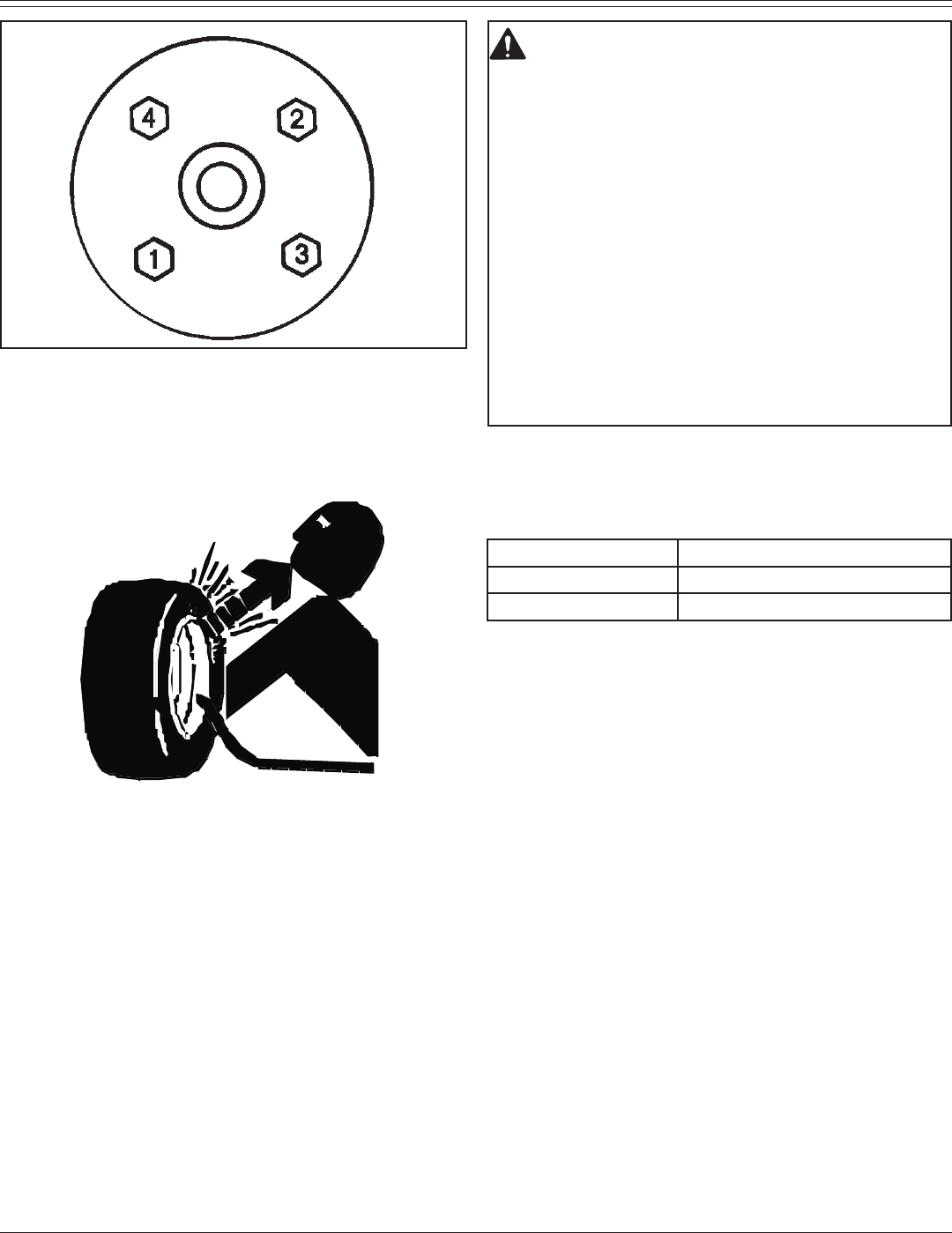

Tighten wheel nuts in numbered sequence shown for

safe wheel installation. Tighten alternately until recom-

mended torque value is reached.

Checking Tire Pressure

2.

CAUTION: Avoid injury! Explosive separation

of tire and rim parts is possible when they are

serviced incorrectly:

Do not attempt to mount a tire without

the proper equipment and experience to

perform the job.

Do not inflate the tires above the recom-

mended pressure.

Do not weld or heat a wheel and tire as-

sembly. Heat can cause an increase in

air pressure resulting in an explosion.

Welding can structurally weaken or de-

form the wheel.

Do not stand in front or over the tire

assembly when inflating. Use a clip-on

chuck and extension hose long enough

to allow you to stand to one side.

•

•

•

•

Check tires for damage.

Check tire pressure with an accurate gauge.

Add air, if necessary:

Tire Size Pressure

Front: 11 x 4 - 5

138–173 kPa (20-25 psi)

Rear: 18 x 6.5 - 8 69–97 kPa (10–14 psi)

Servicing Caster Wheel Roller Bearings

Park machine safely. (See Parking Safely in the

SAFETY section.)

Raise and securely support front of machine.

1.

2.

3.

1.

2.