SERVICE TRANSMISSION

SERVICE TRANSMISSION- 22

• Do not wash paper element.

• Do not attempt to clean paper element by tapping

against another object.

• Do not use pressurized air to clean element.

• Replace element only if it is very dirty, damaged or the

seal is cracked.

NOTE: It may be necessary to check the air filter more

frequently if operating machine in dusty conditions.

Check and clean air filter elements at the intervals recom

-

mended in the Service Intervals section. See the engine

manufacturer’s owner’s manual provided with your machine

for the complete procedure.

Checking Spark Plug

CAUTION: Avoid injury! Touching hot surfaces can

burn skin. The engine, components, and fluids will

be hot if the engine has been running. Allow the

engine to cool before servicing or working near the

engine and components.

Check spark plugs at the intervals recommended in the

Service Intervals section. See the engine manufacturer’s

owner’s manual provided with your machine for the com-

plete procedure.

Cleaning Engine Oil Cooler - Kohler Engines

Keep engine oil cooler fins clear of debris to ensure proper

cooling. See the engine manufacturer’s owner’s manual

provided with your machine for the complete procedure.

Adjusting Carburetor

Carburetor is calibrated by the engine manufacturer and is

not adjustable.

If engine is operated at altitudes above 1829 m (6,000 ft),

some carburetors may require a special high altitude main

jet. See your authorized dealer.

If engine is hard to start or runs rough, check the TROU-

BLESHOOTING section of this manual.

Possible engine surging will occur at high throttle with

transmission in “N” neutral and mower engagement lever

disengaged. This is a normal condition due to the emission

control system.

After performing the checks in the troubleshooting section

and your engine is still not performing correctly, contact

your authorized dealer.

Replacing Fuel Filter

CAUTION: Avoid injury! Fuel vapors are explo-

sive and flammable:

• Do not smoke while handling fuel.

• Keep fuel away from flames or sparks.

• Shut off engine before servicing.

• Cool engine before servicing.

• Work in a well-ventilated area.

• Clean up spilled fuel immediately.

IMPORTANT: Avoid Damage! When installing a new fuel

filter, the filter arrow must be pointed in the direction of

the fuel flow.

Park machine safely. (See Parking Safely in the

SAFETY section.)

Allow engine to cool.

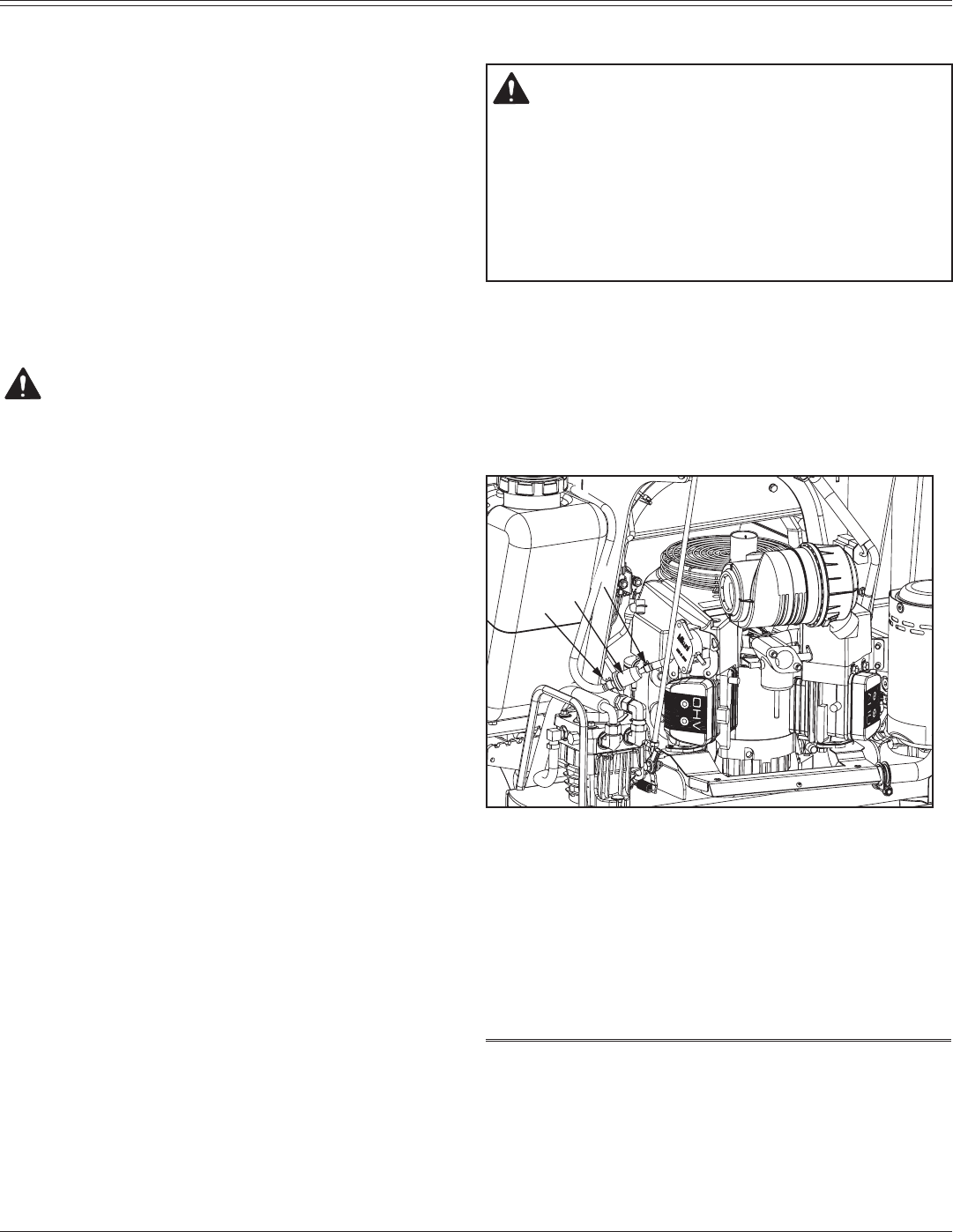

Slide hose clamps (A) away from fuel filter (B).

Place drain pan under hoses to catch any fuel that may

be left in the hoses.

Disconnect hoses from fuel filter (B).

Install new fuel filter (B).

Make sure fuel filter (B) is installed with arrow pointing

in direction of fuel flow.

Connect hoses to new fuel filter (B).

Install hose clamps (A).

Start engine and check for fuel leaks.

1.

2.

3.

4.

5.

6.

•

7.

8.

9.