Maintenance

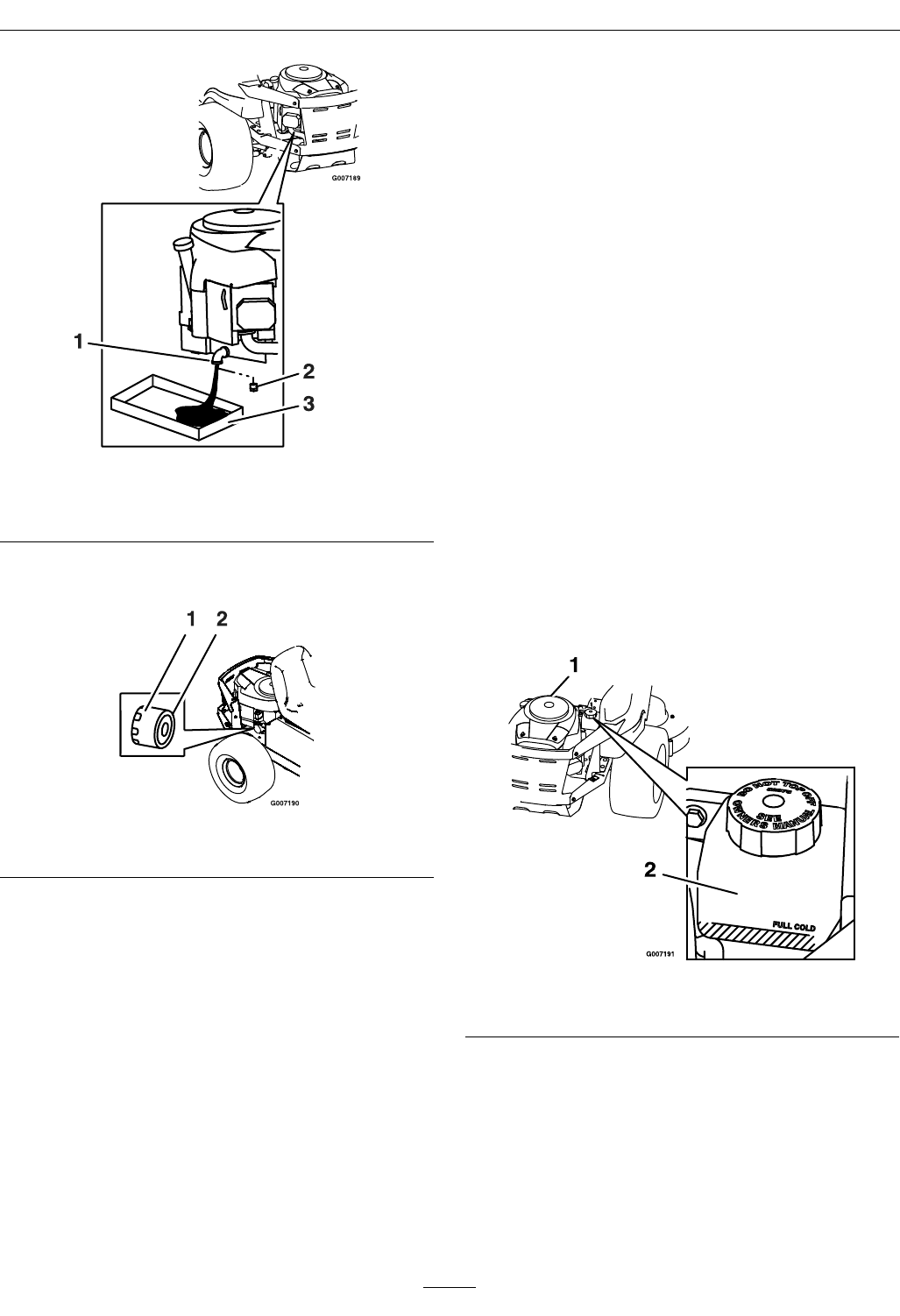

Figure 22

1. Oil drain

3. Pan

2. Oil drain plug

5. Remove the oil drain plug (Figure 22 ). Remove

the oil ll cap/dipstick (Figure 21).

Figure 23

1. Oil lter 2. Gasket

6. Be sure to allow ample time for complete

drainage.

7. Remove the old lter and wipe off the mounting

pad (Figure 23).

8. When the oil has drained completely, install the

oil drain plug. Tighten the plug to 14 N-m (125

in-lb) torque. Wipe up any excess oil on the frame

(Figure 22 ).

Note: Dispose of the used oil at a recycling

center.

9. Apply a thin lm of clean oil to the rubber gasket

on the new lter.

10. Install the replacement oil lter to the mounting

pad. Turn the oil lter clockwise until the rubber

gasket contacts the pad, then tighten the lter an

additional 1/2 to 3/4 turn (Figure 23).

11. Slowly pour approximately 80% of the specied

oil into the ller tube—use oil recommended in

the Engine Owner’s Manual.

12. Install the oil ll cap/dipstick and push rmly

into place.

13. Check the oil level (Figure 21); refer to Checking

the Oil Level.

14. Slowly add additional oil to bring it to the full

mark. Do Not overll.

15. Install the oil ll cap/dipstick and push rmly

into place.

16. Start the engine and check for leaks.

Checking the Hydraulic Oil

Level

Service Interval: Before each use or daily

Check expansion tank and if necessary add Exmark

Premium Hydro oil to the FULL COLD line.

Figure 24

1. Engine 2. Expansion tank

33