Operation

1. Stop the machine and move the drive levers to

the neutral lock position.

2. Disengage the PTO.

3. Engage the park brake.

4. Stop the engine, remove the key and wait for all

moving parts to stop.

5. After adjusting the height of cut, adjust the

anti-scalp rollers by removing the nyloc nut.

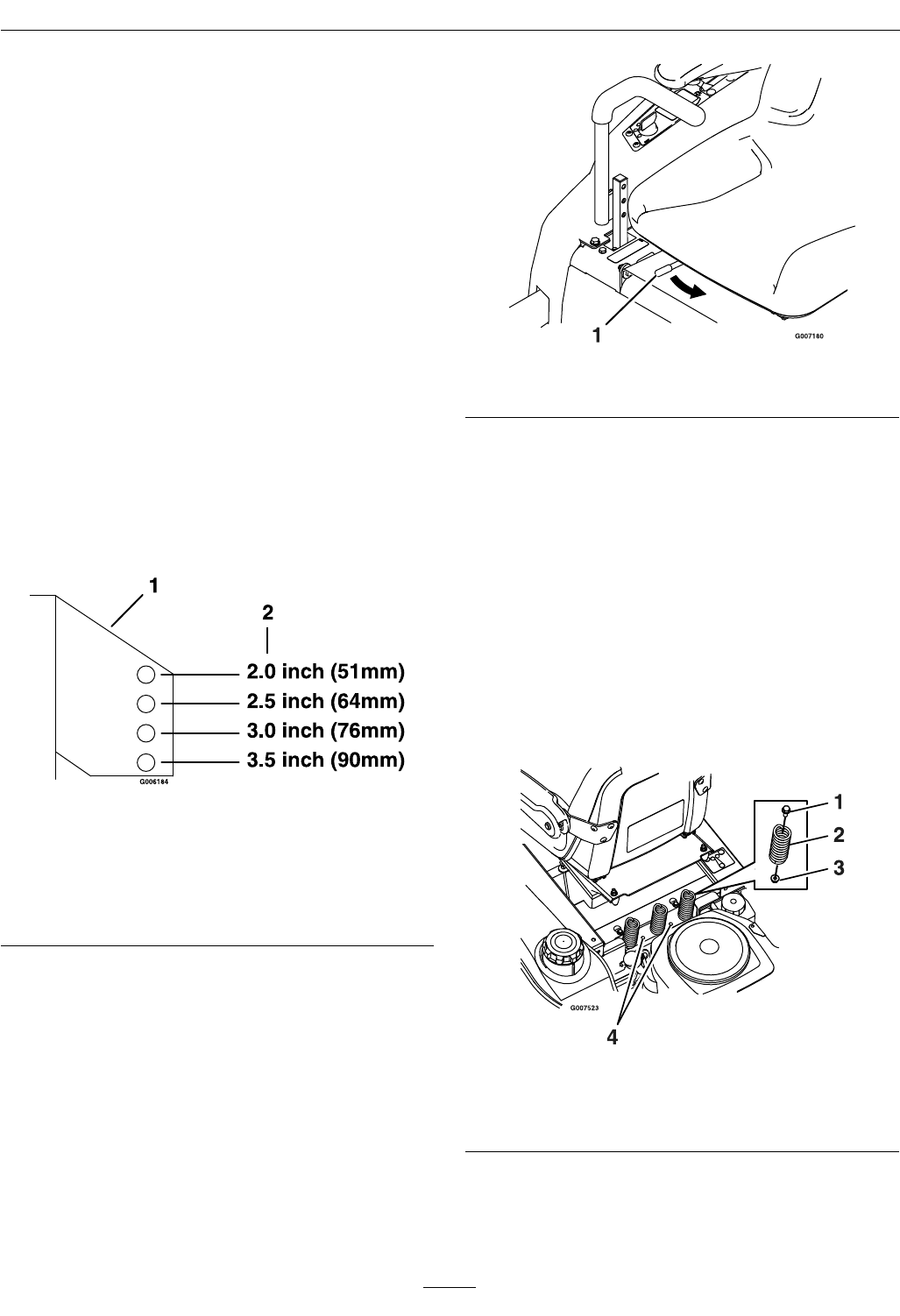

6. Adjust the anti-scalp rollers for the normal

operating conditions. Place rollers in one of

the positions shown in Figure 12. Rollers will

maintain 3/4 inches (19 mm) clearance to the

ground to minimize gouging and roller wear or

damage.

Note: For Maximum Deck Flotation, place

the rollers one hole position lower. Rollers should

maintain 1/4 inch (6.35 mm) clearance to the

ground. Do Not adjust rollers to support the

deck.

Figure 12

For cutting heights above 3 1/2 inches (38 mm) use the

bottom hole. The rollers will still be effective against

scalping.

1. Anti-scalp roller

mounting bracket

2. Cutting height

7. Torque hardware to 27-33 ft-lb (37-45 N-m) or

loss of roller may result.

Positioning the Seat

The seat can move forward and backward. Position

the seat where you have the best control of the

machine and are most comfortable.

1. Push the adjustment lever towards the center of

the machine to release the seat adjuster track

(Figure 13).

Figure 13

1. Adjustment lever

2. Move the seat to the desired position and release

the lever to lock in that position.

Changing the Seat Ride

Suspension

The number of seat springs can be changed to

maximize rider comfort. More springs should be used

with heavier operators and on rough terrain. Fewer

springs should be used with lighter operators and

when mowing smooth, well established lawns. Always

keep the number of springs on the left and right side

the same when adding and removing springs.

Figure 14

1. Bolt 3. Nut

2. Spring

4. Additional mounting

holes

Up to ve springs can be secured to the seat box with

a nut and bolt, see Figure 14.

24