Dayton Operating Instructions and Parts Manual 3WY47, 3W735B, 3W736C, 3WY44, 3TE27A, 3WY45, and 3WY46

16

Dayton Professional-Duty

Electric Generators

®

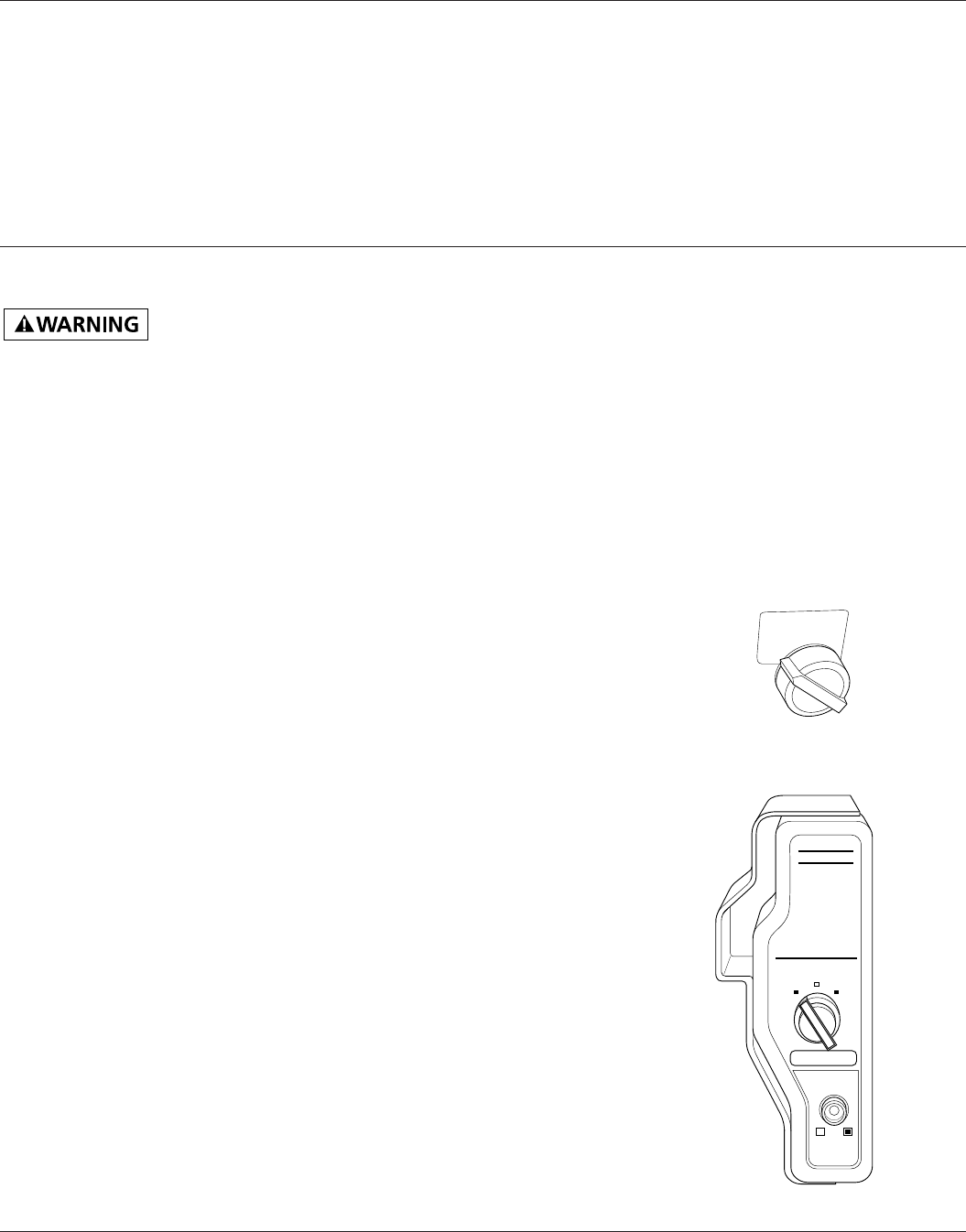

Figure 34 – Engine Switch in OFF Position,

Models 3WY46, 3WY45, and 3WY47

HONDA

OFF

ON

START

ENGINE SW

CIRCUIT

BREAKER

ON/push OFF

OFF

ENGINE SW

ON

Figure 33 – Engine Switch In OFF Position, All

Models Except 3WY46, 3WY45, and 3WY47

Operation (Continued)

HIGH ALTITUDE OPERATION

This generator will not perform well at

high altitudes without proper adjustment.

See engine owner’s manual for details.

ADDING ELECTRICAL LOADS

IMPORTANT: Do not overload generator.

Make sure total wattage of all electrical

loads does not exceed rated wattage of

generator. Overloading may shorten

generator life. It could also cause internal

damage to generator. Overloading

will trip circuit breaker.

IMPORTANT: Keep full power selector

switch in the 120 VOLT ONLY position if

only powering 120V items. Only move

switch to 120/240 VOLT position if

powering 240V items.

1. Check items to be powered. Their

nameplate lists their wattage ratings.

NOTE: The wattage ratings for some

electrical motors are misleading. They may

require 3 to 6 times their rated wattage to

start. You must figure total electrical load

wattage. Make sure total wattage of all

electrical loads does not exceed rated

wattage of generator. See “Determining

Electrical Load for Generator,” page 11.

2. Start engine. Let engine reach full

speed.

3. Connect electrical loads one at a time. If

the load consists of electric motors, start

them first. Always start the largest first.

Start each motor individually.

DISCONNECTING ELECTRIC LOADS

Remove electrical loads one at a time.

Remove voltage sensitive items first.

Voltage sensitive items include TVs, VCRs,

and other home electronic items.

STOPPING ENGINE

IMPORTANT: The engine speed is preset.

The throttle is locked in preset position. Do

not adjust throttle.

Follow the steps below to stop engine.

1. Remove all electrical loads from

generator (See “Disconnecting Electrical

Loads,” above). Remove electrical loads

one at a time.

2. Let engine run for two or three minutes

after removing electrical loads. This lets

engine cool slightly.

3. Turn engine switch to the OFF position

(See Figures 33 and 34).

Always set the idle

speed before

turning on the auto-idle. If idle speed

is not set, the larger resistor on the

control board may become hot. Heat

from the resistor may damage the

protective coating on the control

board.

5. Slowly pull solenoid bracket away

from engine (on Model 3WY47 this

will require bending the bracket

slightly).

6. With a volt meter, check the no-load

output voltage at the 120-volt duplex

receptacle. At proper idle speed (2680

minimum RPM) the meter should read

50-60 volts. Lower settings will cause

the auto-idle to not operate properly.

7. After reaching proper idle speed,

tighten M8 nut to secure solenoid

mounting bracket (Models 3WY46

and 3WY45 only).

8. Turn auto-idle switch ON. Make sure

solenoid is engaged. When engaged,

the plunger is pulled back into the

solenoid.

9. If the engine speed is too slow, the

engine will want to "hunt" or speed

up and slow down repeatedly. When

this occurs, increase engine speed by

adjusting throttle stop screw on

carburetor (refer to Carburetor

Adjustment in Honda Engine Manual).

10. Replace the engine linkage cover

(Models 3WY46 and 3WY45 only).