Dayton Operating Instructions and Parts Manual 3WY47, 3W735B, 3W736C, 3WY44, 3TE27A, 3WY45, and 3WY46

10

Dayton Professional-Duty

Electric Generators

®

Installation

FUEL

Gasoline presents a

hazard of fire or

explosion. Gasoline

is flammable. Its vapor is explosive.

• Keep fuel out of children’s reach.

• Refuel generator in a well-vented

area. Do not fill fuel tank in the dark.

Do not refuel while engine is

running. Unhook all electrical loads

and shut off engine before refueling.

• Do not overfill fuel tank. Always

allow room for fuel to expand. If you

overfill tank, fuel can overflow onto

hot engine. This can cause fire or

explosion. After refueling, tightly

close fuel tank cap.

• Do not spill fuel. Fuel or fuel vapor

may ignite. If fuel spills, make sure

area is dry before starting engine.

• Never smoke in refueling area. Never

allow open flames or sparks in area.

• Store fuel in approved container.

Store fuel in a well-vented area free

of open flames or sparks.

Use clean, fresh, unleaded gasoline. Use

gasoline with octane rating of 86 or

higher. Service station gasoline pumps

should display the octane rating. Using

gasoline with lower octane level could

damage engine. Avoid getting dirt, dust,

or water in fuel tank. Do not mix oil with

gasoline. See engine owner’s manual for

more information.

ENGINE OIL

We ship the generator without oil in the

engine crankcase. You must add oil before

starting engine. See engine owner’s

manual for specific oil type.

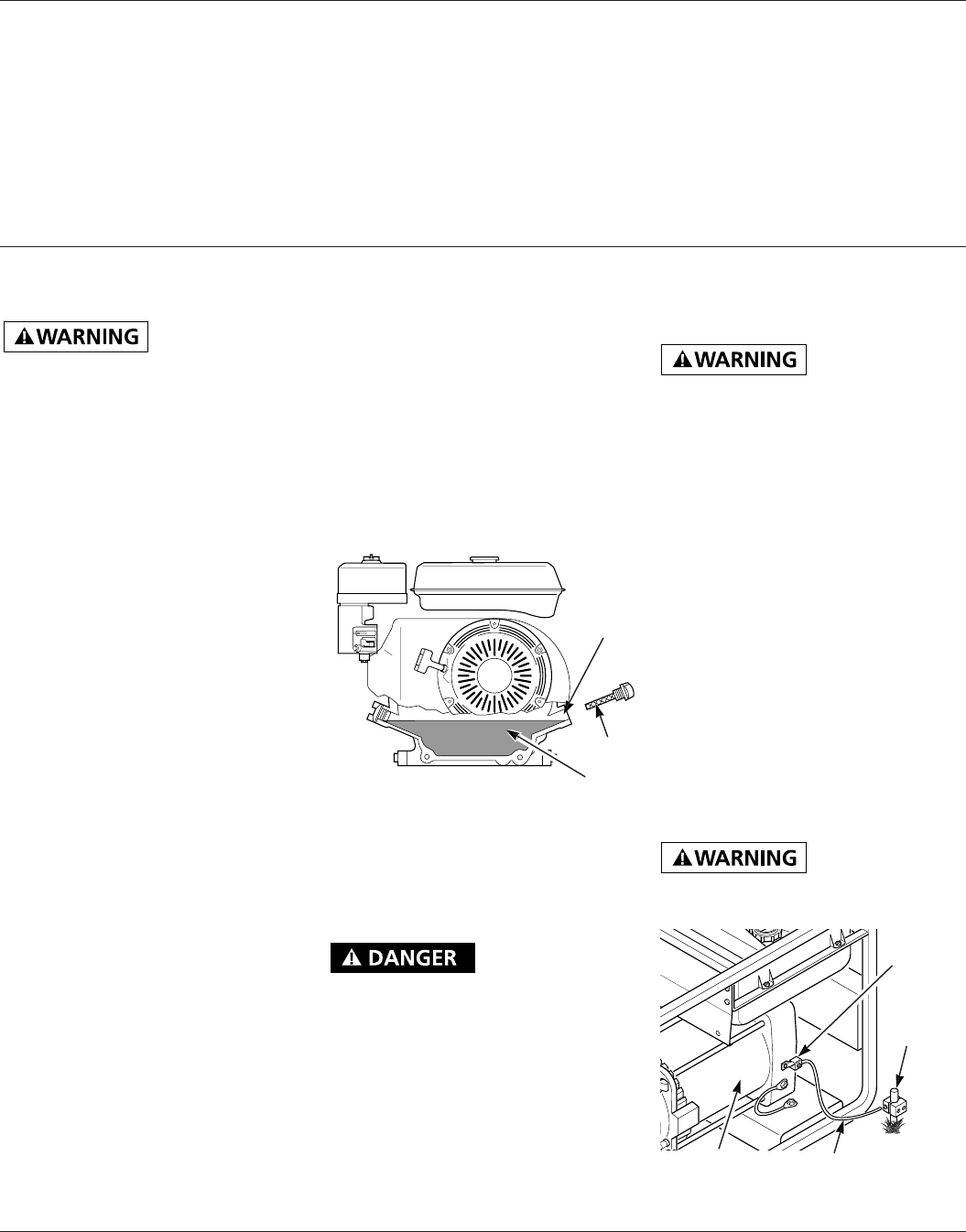

CHECKING OIL LEVEL AND ADDING OIL

Follow steps below to check oil level.

Make sure engine is level and stopped.

1. Remove dipstick (See Figure 19). Wipe

dipstick clean.

2. Insert dipstick into oil filler neck. Do not

screw it in. Oil level should be at top of

filler neck. Oil should cover most of

dipstick. For Model 3WY47 only, oil level

should be between two dots on dipstick.

3. If level is low, fill to top of oil filler neck

(See Figure 19). Only use oil recommended

in engine owner’s manual. For Model

3WY47 only, fill to top dot on dipstick.

Oil

Oil Level

At Top

Of Filler

Neck

Dipstick

Figure 19 – Checking Oil Level (Model

3W735B Shown)

VENTILATION

Use only in well-

vented areas. Make

sure area has plenty of free-moving,

fresh, outside air. Never run generator

in an enclosed or confined area. Never

run generator inside occupied building.

Engine exhaust contains poisonous

carbon monoxide gas. Overexposure

will cause loss of consciousness and

will lead to death.

This generator needs cooling air to run

properly. Never block free-flowing, cooling

air to generator. Overheating will occur

without cooling air. This will damage the

GENERATOR GROUNDING

You must properly

earth-ground

generator before starting. This will

help guard against deadly electric

shock. Only use grounded plugs with

generator. Only use grounded exten-

sion cords. Only use three-wire or

double-insulated power tools.

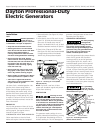

Grounding generator helps prevent electric

shock from a ground fault condition.

Locate ground lug on end of generator

housing (See Figure 20). Attach a #10

stranded-copper ground wire to ground

lug. Drive grounding point into ground.

Grounding point can be a stake, ground-

ing rod, or pipe. Grounding point should

be copper or brass. Attach ground wire to

grounding point. You must supply the

ground wire and grounding point. These

do not come with generator. Follow the

National Electrical Code and all state and

local codes. Consult your power company

or a licensed electrician.

Copper or

Brass

Grounding

Point

Ground

Lug

Alternator

Ground Wire

For a grounding

point, do not use

metal pipe being used to carry combus-

tible materials or gases.

Figure 20 – Grounding Generator

(Model 3WY45 Shown)

generator. Keep generator at least three

feet away from any object.

NOTE: If oil level is too low, oil alert

system will shutdown engine and prevent

engine from restarting.