20

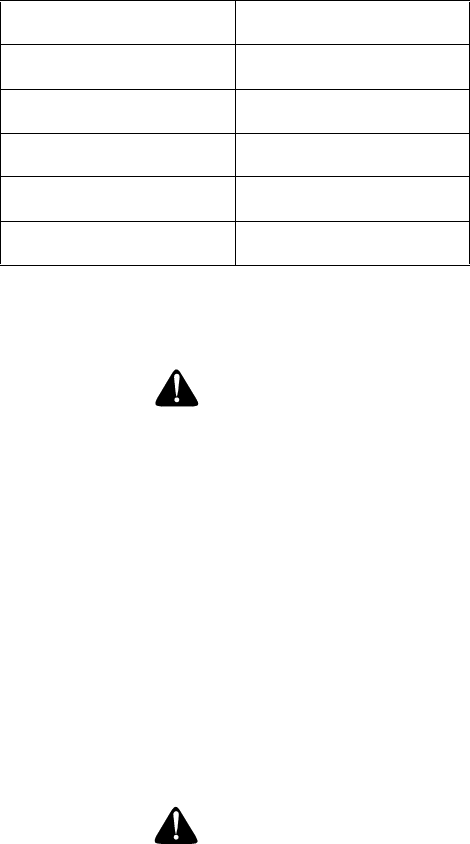

c. Store the battery with a full charge. A dis-

charged battery will freeze (refer to the

table below).

d. Recharge battery when ever the specific

gravity value is less than 1.225

3. Battery Removal

Warning:

When removing the cables from the battery

follow these steps to avoid a short between

the wrench and the frame.

a. Remove the Negative (black) cable.

b. Remove the Positive (red) cable.

c. Release the hold down straps.

d. Remove the battery without tipping.

4. Installing the Battery

Note: The battery is delivered from the fac-

tory fully charged and filled with electrolyte.

a. Attach the Positive (red) cable.

b. Attach the Negative (black) cable.

c. Attach the rubber battery strap.

5. Jump Starting

Warning:

Note: For E.F.I. Tanks, the battery must be

disconnected (Negative lead) for storage

exceeding four weeks. Do not “Jump Start” an

E.F.I. unit, recharge or replace battery to avoid

damage to the Electronic Control Unit (ECU).

Failure to use this starting procedure can

cause sparking, and the gases in the battery

to explode.

a. Attach the end of the red jumper cable to

the Positive terminal (+) of the charged

battery.

b. Attach the other end of the red jumper

cable to the Positive terminal (+) of the low

charge battery.

c. Attach the end of the black jumper cable to

the Negative terminal of the charged bat

-

tery.

d. Attach the other end of the black jumper

cable to the frame of the unit with the low

charge battery.

6.

Fuses:

There is one fuse located in the wiring

between the ignition and start switch and

other electrical components. This is a stan

-

dard plug-in type automotive fuse rated at 7.5

amp.

7.

Safety Switches:

There are three safety

switches in the electrical circuit which control

the engine. They are (1) the blade clutch

switch, (2) the steering lever/parking brake

switch, and (3) the seat switch.They operate

so that in order to start the engine, the blade

clutch switch must be off, the parking brake

must be engaged, and both steering levers

must be in the neutral position. Once the

engine is started, the seat must be occupied

and the parking brake must be released

before either of the steering levers can be

moved. Also, the seat must be occupied

before the blade clutch switch can cause the

blades to rotate.

8.

Safety Switch Operation Checks:

The fol-

lowing operational checks should be made

daily.

a. Blade Clutch Switch: Sit in the operator’s

seat. With both steering levers in the neu

-

tral position and the parking brake

engaged, turn the blade clutch switch “on”

and try to start the engine. The engine

should not start. If it does, the blade clutch

switch must be replaced. If the engine

does not start, turn the blade clutch switch

“off” and start the engine. Now turn the

blade clutch switch “on” and the blades

should rotate. If the blades do not turn, the

blade clutch switch must be replaced, the

seat switch must be replaced or the elec

-

tric PTO clutch must be repaired.

The air-gap should be checked every 100

hrs. (or less, if severe operating conditions

exist such as when there are many on/off

cycles, mulching operations, material col

-

lection systems used, and dusty/dirty con-

ditions), and the air-gap adjusted if more

than 0.025". To inspect, remove the “nega

-

tive” cable from the battery and all spark-

plug wires. The air-gap should be checked

with feeler gages in the three slots of the

BBC (PTO Clutch). See page 22 for air gap

adjustment specs. There are three inspec

-

tion slots in the brake cover. To adjust, suc-

cessively tighten each of the three gap

adjustment nuts an equal amount. Insert a

feeler gage (see page 22 for specs) into

each slot as the air gap adjustment nut are

tightened. The correct adjustment occurs

Specific Gravity Freezing Temp (°F)

1.265 -71

1.250 -62

1.200 -16

1.150 5

1.100 16