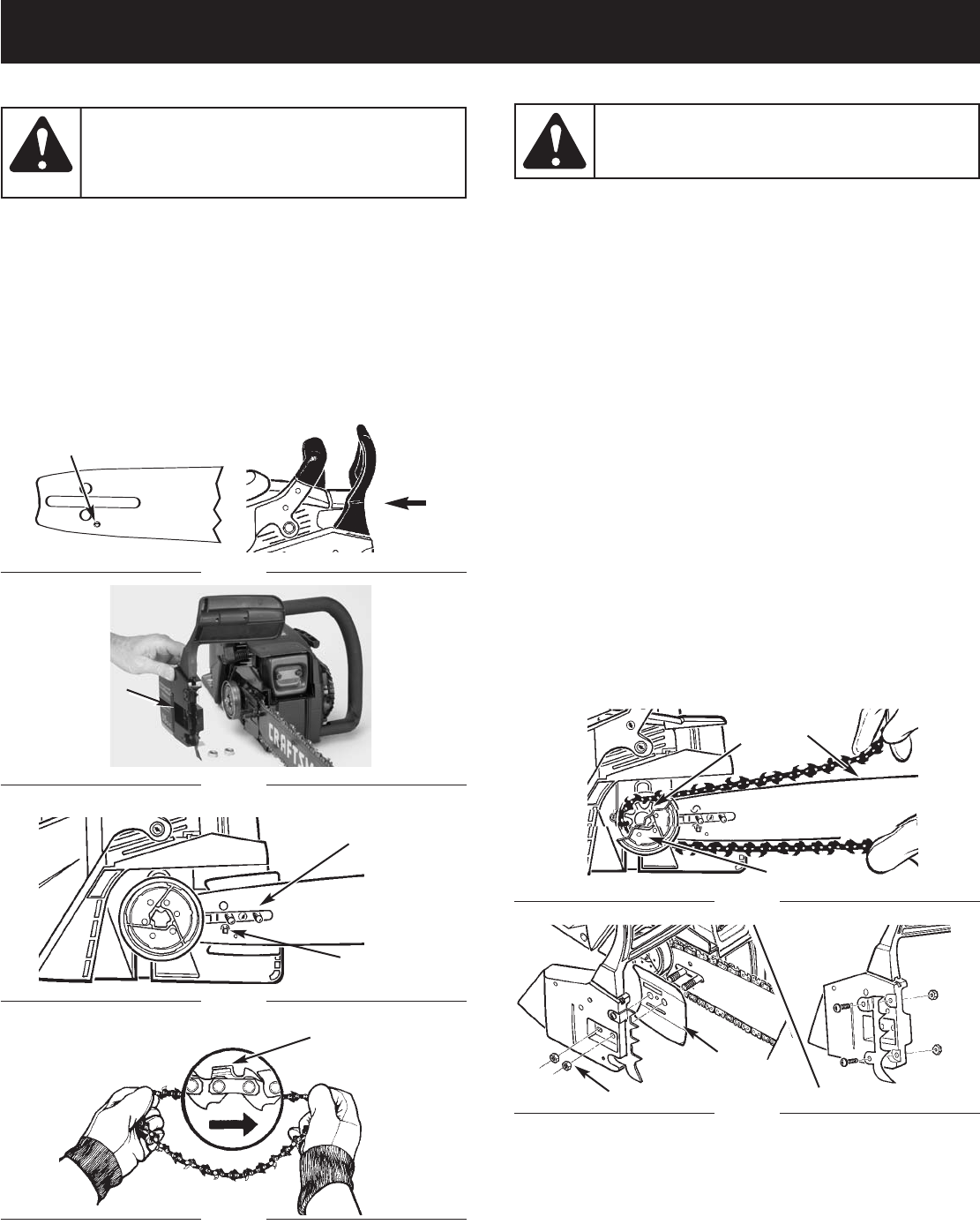

REMOVING GUIDE BAR AND CHAIN

NOTE: Always wear heavy gloves when handling the

saw chain.

1. Make sure the Chain Brake® lever is pulled back into

the DISENGAGED position (Fig. 21). Remove bar

retaining nuts with supplied multi-purpose tool (Fig.

22).

2. Remove chain brake cover (C, Fig. 22) and outer

guide bar plate (I, Fig. 27) by pulling straight out (Fig.

22).

3. Slide bar off the two bar bolts and remove chain (Fig.

23).

REPLACING GUIDE BAR AND CHAIN

1. Spread chain out in a loop with cutting edges (E)

pointing CLOCKWISE around loop (Fig. 24).

2. Slip the chain around the sprocket (F) behind the

clutch (G). Make sure the links fit between the sprock-

et teeth (Fig. 25).

3. Place the slotted end of the guide bar over the two

bar bolts (D, Fig. 23). Be sure adjusting tang

(J, Fig. 23) is in lower adjusting hole of the bar.

4. Guide the drive links into the groove (H) and around

the end of the bar (Fig. 25).

5. The chain will be tight so you will have to rotate the

clutch clockwise by hand so the chain engages the

bar sprocket.

6. Replace the outer guide bar plate (I) so the bent

edges (top and bottom) are directed away from the

chain (Fig. 27).

7. Install the Chain Brake® cover (Fig. 27). Make sure

the chain does not slip off of the bar. Install the 2 bar

retaining nuts hand tight and follow instructions in

Saw Chain Tension Adjustment.

NOTE: The guide bar retaining nuts are installed only

hand tight at this point because saw chain adjust-

ment is required. Follow instructions in Saw Chain

Tension Adjustment.

Always use protective

gloves when handling

the saw chain.

WARNING:

To ensure the bar and

chain receive oil, ONLY

USE THE ORIGINAL STYLE BAR with the oil

passage hole (A) as illustrated in Fig. 21.

CAUTION:

E

MAINTENANCE AND REPAIR INSTRUCTIONS

A

D

Fig. 21

Fig. 22

Fig. 23

H

I

G

Fig. 25

Fig. 27

B

C

Fig. 24

F

16

J

B

MAINTENANCE AND REPAIR INSTRUCTIONS

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the fre-

quency stated in the table. These pr

ocedures should also

be a part of any seasonal tune-up.

NOTE: Maintenance, r

eplacement, or repair of the

emission control devices and system may only be

performed by a Sears or other qualified service

dealer.

NOTE: Maintenance, replacement, or repair of the emis-

sion control devices and system may be per-

for

med by a Sears or other qualified service dealer.

To prevent serious

injury, never perform

maintenance or repairs with unit running.

Always service and repair a cool unit.

Disconnect the spark plug wire to ensure that

the unit cannot start.

WARNING:

A good preventive maintenance program of regular inspection and care will increase life and improve performance of your

chain saw. This maintenance checklist is a guide for such a program.

Cleaning, adjustment, and part replacement may be required, under certain conditions, at more frequent intervals than

those indicated.

CUSTOMER RESPONSIBILITY

CHECK FOR LOOSE SCREWS/

NUTS/BOLTS

CLEAN OR REPLACE THE AIR FILTER

REPLACE SPARK PLUG

REPLACE OIL / FUEL FILTER

CLEAN, INSPECT SPARK PLUG

ARRESTOR SCREEN / MUFFLER

CHECK GUIDE BAR AND CHAIN OIL,

FUEL HOSES

CLEAN UNIT AND INSPECT DECALS

CHECK CHAIN BRAKE® COMPONENTS

CLEAN GUIDE BAR GROOVE

CHECK FOR DAMAGED / WORN P

AR

TS

CHECK CHAIN TENSION

CHECK CHAIN SHARPNESS

LUBRICA

TE SPROCKET TIP

CHECK FUEL MIXTURE

ITEM BEFORE EACH USE 10 20

MAINTENANCE CHECKLIST

AFTER

EACH USE

HOURS OF OPERA-

TION

15