FdcUon

Bearing

Bolts

Fasteners

i

i

i--

Unit Standingon Auger HousingEnd

• Remove right side bearing plate. Leave

hex shaft in original position.

• Remove friction wheel from hub. Slip fric-

tion wheel oft hex shaft towards right side.

See figure below.

• Position new friction wheel onto hub. See

Figure below.

Friction Wheel

Shaft

Bolt

Nut

• install bearing plates to original position.

Ensure hex shaft is engaged with both

bearing plates.

• Secure bearing plates, using bolts re-

moved earlier.

• Secure friction.wheel to hub using fasten-

ers removed earlier. Ensure hex shaft

tums freely.

• Should friction wheel require adjustment

(see To Adjust the Friction Wheel on

page 20).

NOTE: Ensure friction wheel and friction

disc are free from grease or oil."

• Replace bottom panel•

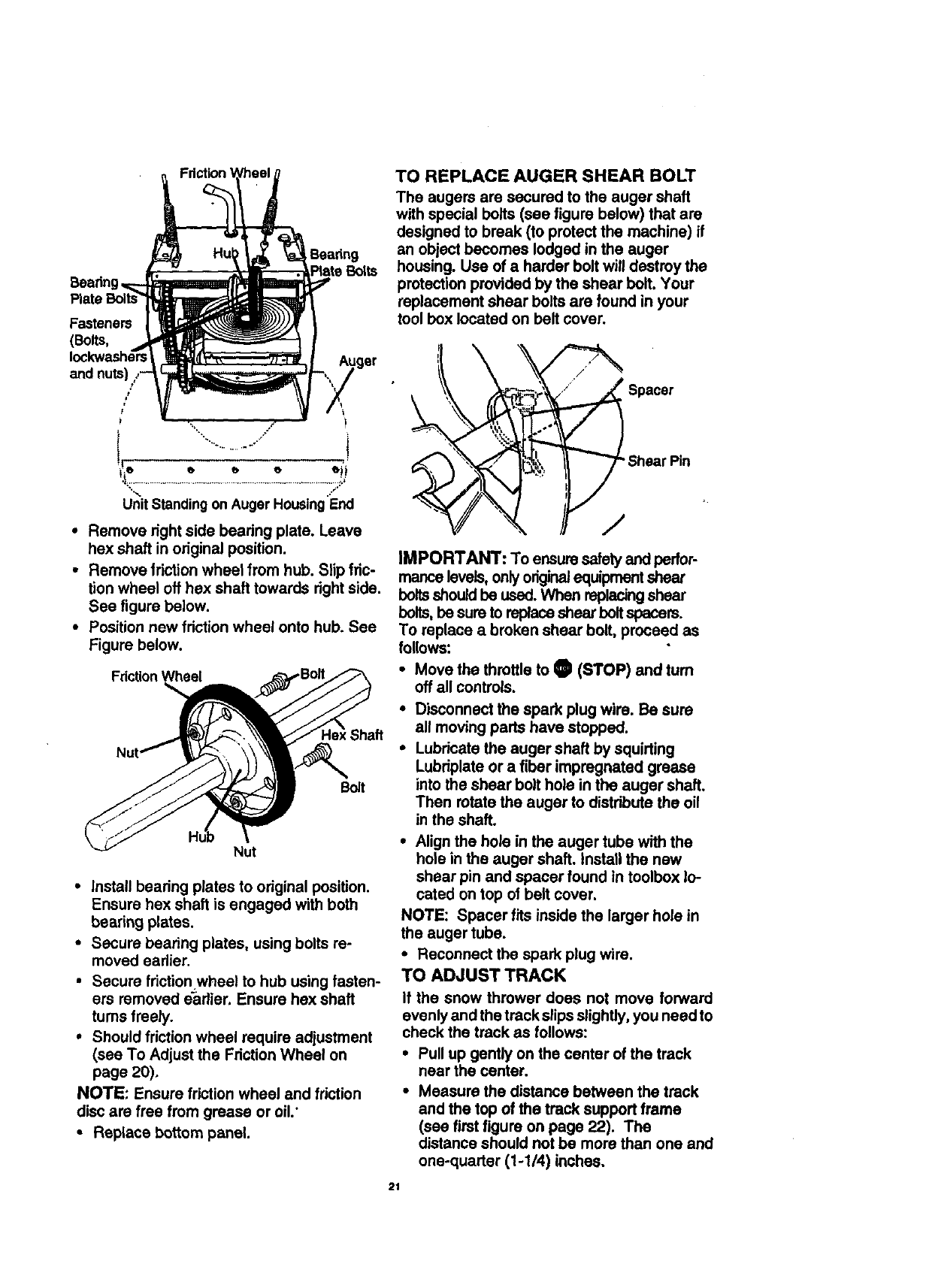

TO REPLACE AUGER SHEAR BOLT

The augers are secured to the auger shaft

with special bolts (see figure below) that are

designed to break (to protect the machine) if

an object becomes lodged in the auger

housing. Use of a harder bolt will destroy the

protection provided by the shear bolt. Your

replacement shear bolts are found in your

tool box located on belt cover.

IMPORTANT: To ensure safety and perfor-

mance levels, only originalequipment shear

boltsshouldbe used. When replacingshear

bolts, be sure to replace shear bolt spacers.

To replace a broken shear bolt, proceed as

follows:

• Move the throttle to O (STOP) and turn

off all controls.

Disconnect the spark plug wire. Be sure

all moving parts have stopped.

Lubricate the auger shaft by squirting

Lubriplate or a fiber impregnated grease

into the shear bolt hole in the auger shaft.

Then rotate the auger to distribute the oil

in the shaft.

• Align the hole in the auger tube with the

hole in the auger shaft, install the new

shear pin and spacer found in toolbox lo-

cated on top of belt cover.

NOTE: Spacer fits inside the larger hole in

the auger tube.

• Reconnect the spark plug wire.

TO ADJUST TRACK

it the snow thrower does not move forward

evenly and the track slips slightly, you need to

check the track as follows:

• Pull up gently on the center of the track

near the center.

• Measure the distance between the track

and the top of the track support frame

(see first figure on page 22). The

distance should not be more than one and

one-quarter (1-1/4) inches.

21