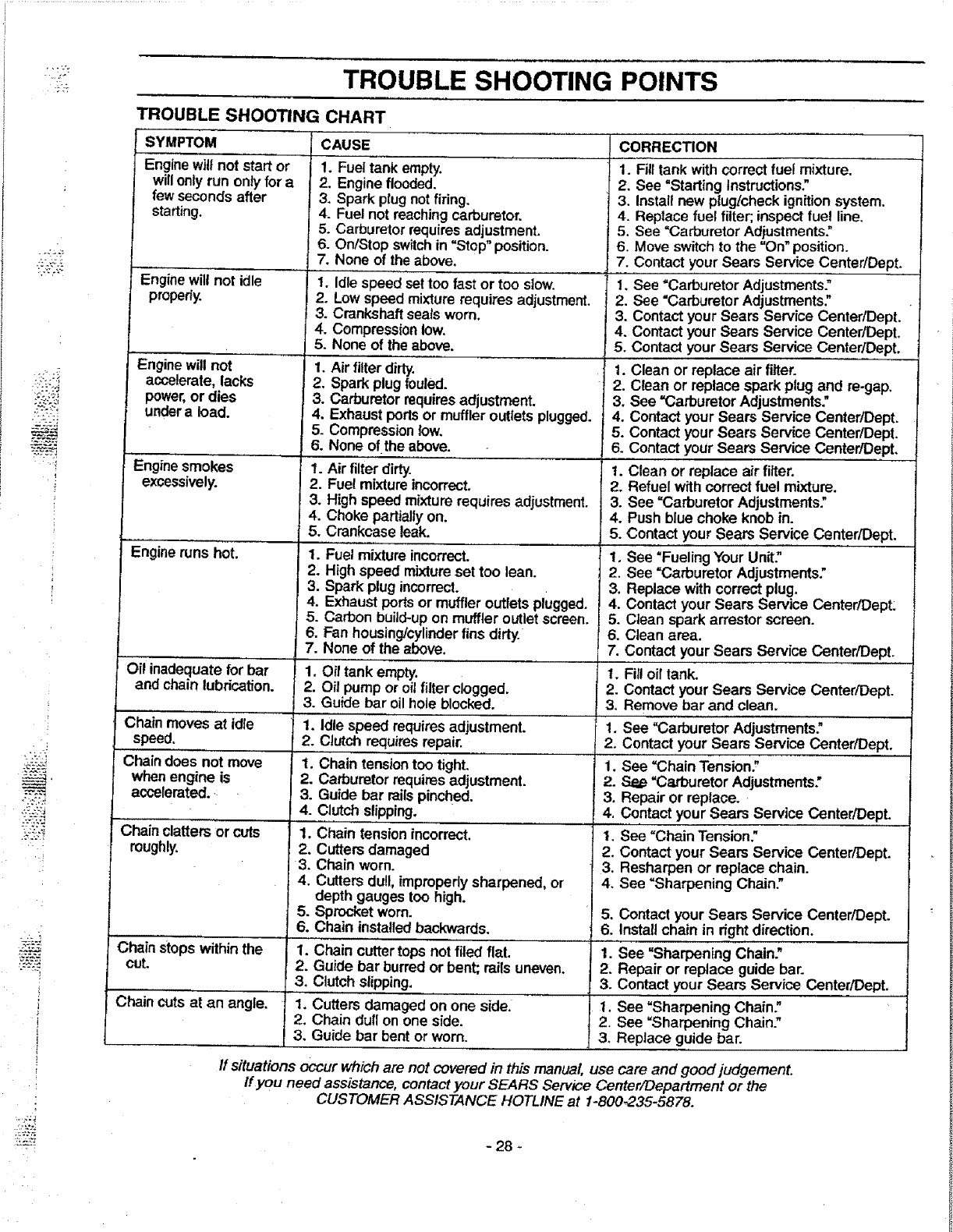

TROUBLE SHOOTING POINTS

TROUBLE SHOOTING CHART

SYMPTOM

Enginewiltnot start or

willonlyrun onlyfor a

few secondsafter

starting.

EngineWillnot idle

properly.

Enginewillnot

accelerate,lacks

power, or dies

undera load.

Enginesmokes

excessively.

Engine runshot.

Oil inadequate for bar

and chainlubrication.

Chain moves at idle

speed,

Chain does not move

whenengine is

accelerated.,

'Chainclattersor cuts

roughly.

Chain''stopsWithinthe

cut.

3hain cutsat an angle,

CAUSE

1. Fueltank empty.

2. Engine flooded.

3. Spark ptug not firing.

4. Fuel not reaching carburetor.

5. Carburetor requiresadjustment.

6. On/Stop swilch in "Step" position.

7. None of theabove,

1. Idle speed settoo fast or too slow.

2. Low speed mixture requires adjustment.

3. Crankshaft seats worn.

4. Compression low.

5. None of the above.

1. Air filter dirty, '

2. Spark plug fouled.

3. Carburetor requires adjustment.

4. Exhaustports or muffler outlets plugged.

5. Compression low.

6. None of the above.

1. Air filter dirty.

2. Fuel mixture incorrect.

3. High speed mixture requires adjustment.

4. Choke partially on.

5. Crankcase leak.

1. Fuel mixture incorrect......

2. High speed mixture set too lean.

3. Spark plug incorrect.

4. Exhaust ports or muffler outlets plugged.

5. Carbon build-up on muffler outlet screen.

6. Fan housing/cylinder fins dirty.

7. None of the above.

1. Oil tank empty.

2. Oil pump or oil filter clogged.

3. Guide bar oil hole blocked.

1. Idle speed requires adjustment.

2. Clutch requires repair.

1. Chain tension too tight.

2. Carburetor requires adjustment.

3. Guide bar rails pinched.

4, Clutch sl!pplng.

1. Chain tensionincorrect.

2. Cuttersdamaged

3. Chain worn.

4. Cuttersdull, improperlysharpened, or

depthgauges too high.

5. Sprocketworn.

6. Chain installedbackwards.

1. Chain cuttertops notfiledfiat.

2. Guide bar burredor bent; railsuneven.

3. Clutch slipping,

1. Cutters damaged on one Side.

2. Chain dull on one side.

3, Guide bar bent or worn.

CORRECTION

1. Fi!l tank withcorrect fuel mixture.

2. See "StartingInstructions."

3. Installnew plug/checkignitionsystem.

4. Replace fuel filter; inspectfuel line.

5. See "Carburetor Adjustments."

6. Move switch to the =On"position.

.,7:Contactyour Sears Service CentedDept.

t. See "Carburetor Adjustments."

2. See =CarburetorAdjustments."

3. Contact your Sears Service CentedDept.

4. Contact your Sears Service Center/Dept.

5. Contact your Sears Service Center/Dept.

1. Clean or replace air filter.

2. Clean or replace spark plugand re-gap,

3. See "Carburetor Adjustments."

4. Contact your Sears Service CentedDept.

5. Contact your Sears Service Center/Dept.

6. Contact your Sears Service Center/DePt.

t. Clean or replace air filter.

2. Refuel with correct fuel mixture.

3. See =Carburetor Adjustments."

4. Push blue choke knob in.

5. Contact your Sears Service Center/Dept.

1. See "Fueiing You; Unit.".......

2. See "CarburetorAdjustments."

3. Replace with correct plug.

4. Contact your Sears Service center!Dept.

5. Clean spark arrestor screen.

6. Clean area.

7. Contact......... your Sears Service center/Dept.

t. Fitloil tank,

2. Contact your Sears Service Center/Dept.

3. Remove bar and c!earl ,.........

1. See "Carburetor Adjustments."

2. Contactyour Sears Service center/Dept.

1. See =ChainTension."

2. SP_ =CaJ'buretorAdjustments."

3. Repair or replace.

4, Contact your Sears Service Center/Dept.

1, See "Chain Tension."

2. Contact your Sears Service Center/Dept.

3. Resharpen or replace chain.

4. See "Sharpening Chain."

5. Contact your Sears Service Center/Dept.

6. Installchain in right direction.

.....11See =Sharpening Chain."

2. Repair or replace guide bar.

3. Contact your Sears Service center/Dept.

! 1. See "Sharpening Chain."

2. See "Sharpening Chain."

3. Replace guide bar.

ff situations occur which are not covered in this manual, use care and good judgemenL

ff you need assistance, contact your SEARS Service Center/Department or the

CUSTOMER ASSISTANCE HOTLINE at 1-800-235-5878.

- 28 -