CUSTOMER RESPONSIBILITIES

1 FULL VtEW ]

I SIDE VIEW I

File Holder

1FRONT VIEW 1

"-Guide Bar

& Chain

Figure 23

Outside

/

Inside_

Figure 24

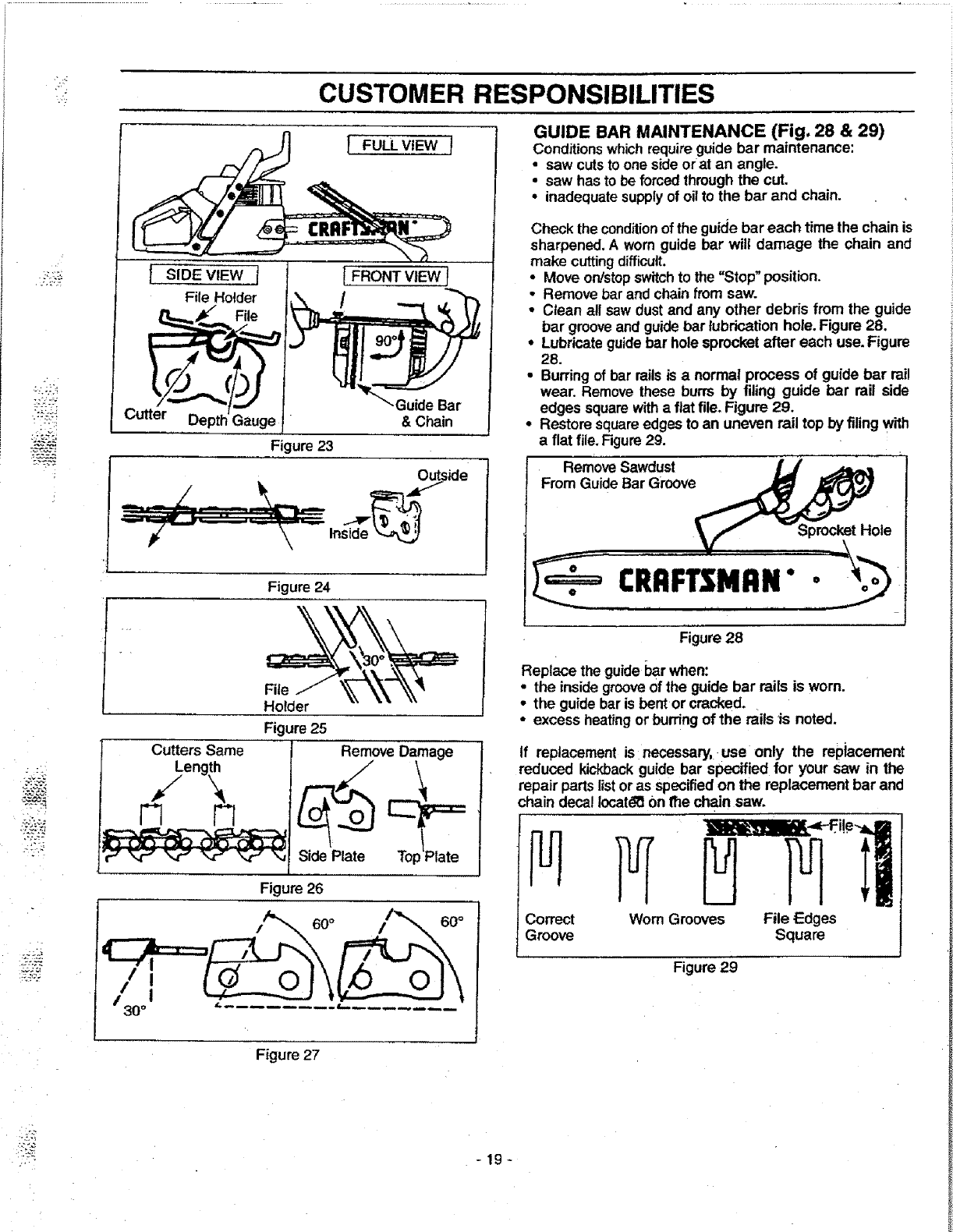

GUIDE BAR MAINTENANCE (Fig. 28 & 29)

Conditionswhichrequireguide bar maintenance:

• saw cutstoone side orat an angle.

• saw has to be forced through the cut.

• inadequate supply of oilto the bar and chain.

Check theconditionof the guide bar each time the chain is

sharpened, A wornguide bar will damage the chain and

make cuttingdifficult.

• Move on/stop switch to the "Stop _position.

• Remove bar and chainfrom saw.

• Clean all saw dust and any other debris from the guide

bar groove and guide bar lubrication hole. Figure 28.

• Lubricateguide bar hole sprocketafter each use. Figure

28.

• Burring of bar rails is a normal process of guide bar rail

wear. Remove these burrs by filing guide bar rail side

edges square with a flat file. Figure 29.

• Restore squareedges to an uneven rail top by filing with

a flat file. Figure 29.

RemoveSawdust l_f'

FromGuideBar Groove _ j_7_

- Sprec_t Hole

CRRFTSMRN"•

I

I

30o

Cutters Same

2e°o ,

n

File

Holder

Figure 25

t Remove Damage

Side Plate TopPlate

Figure 26

Figure 28

Replace theguide bar when:

• the inside grooveof the guide bar rails is worn.

• the guide bar isbent or cracked.

• excess heating orburring of the rails'is noted.

If replacement is necessary, use only the repiacernent

reduced kickback guide bar specified for your saw in the

repair parts list or as specified on the replacement bar and

chain decal locat_ Onthe chain saw.

Correct Worn Grooves

Groove

File Edges

Square

Figure 29

Figure 27

-19-